Rotary spherical trash rack

A trash rack and rotary technology, applied in the field of rotating spherical trash racks, can solve the problems of clogging the water outlet and hindering the water flow rate of the water inlet, and achieve the effects of increasing water intake, simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

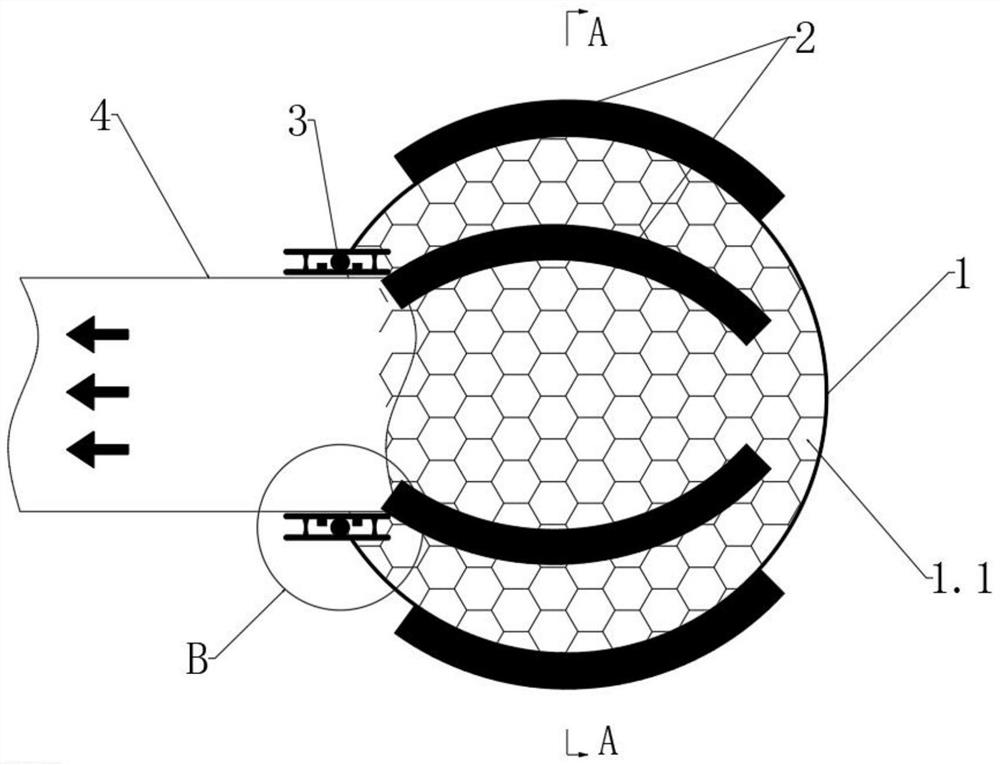

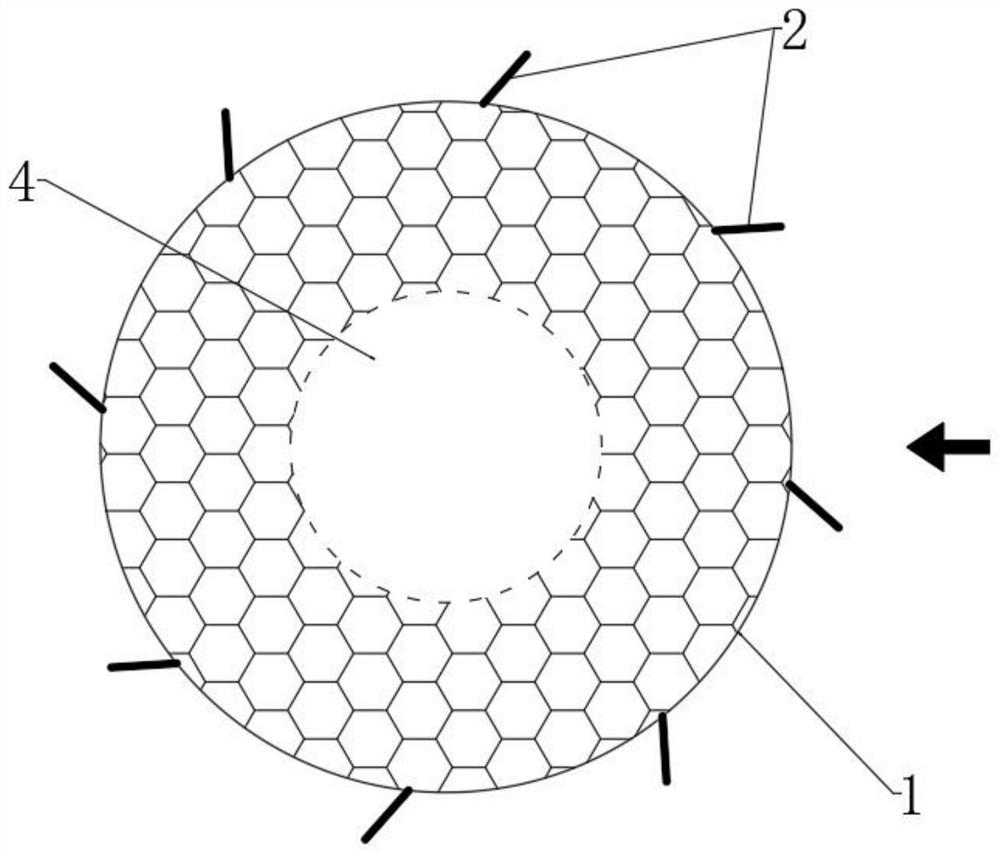

[0016] combined with Figure 1~2 , a rotating spherical trash rack, comprising a trash rack 1, the trash rack 1 is in a spherical shape, and its outer ring is provided with a rotating blade 2 fixedly connected to it, and the trash rack 1 is connected to the trash rack by a rotating device 3 The water pipe 4 is connected in a rotating and sealed manner, and the central axis of the rotating device 3 is on the same axis as the central axis of rotation of the trash rack 1 and the rotating blade 2 .

[0017] As a preferred implementation of this embodiment, the trash rack 1 is provided with uniformly arranged grid holes 1.1 along its spherical surface, and the grid holes 1.1 are in the shape of a regular hexagon.

[0018] As a preferred implementation of this embodiment, the rotating blades 2 are in the shape of fan blade arcs, which are evenly arranged on the outer ring of the trash rack 1 .

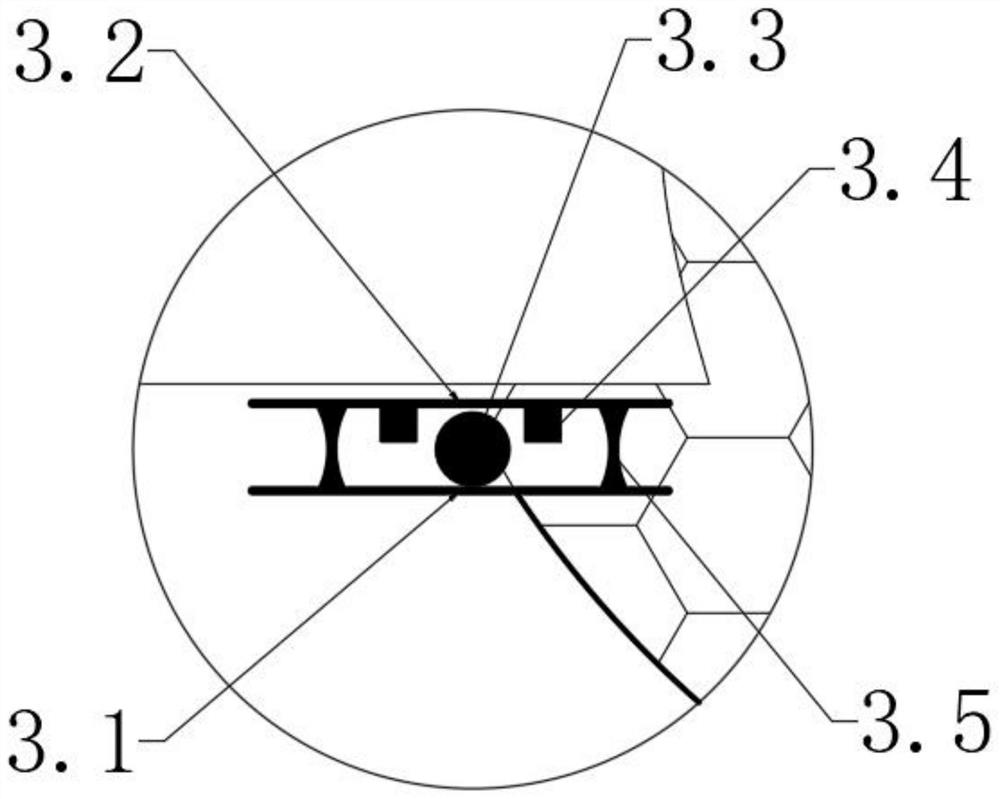

[0019] As a preferred implementation of this embodiment, the rotating device 3 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com