Tunnel double-layer inverted arch construction formwork, trestle and construction method

A formwork and double-layer technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of occupying tunnel space, high labor intensity, and inability to install, so as to ensure construction quality, improve construction efficiency, and reduce space occupation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

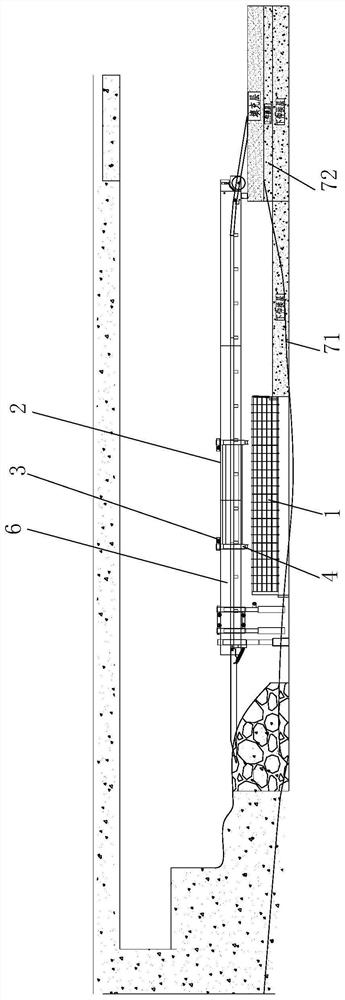

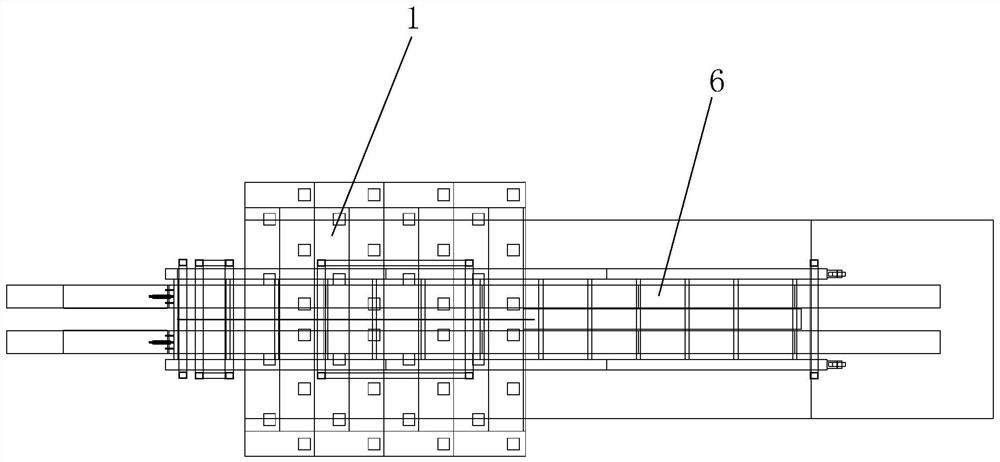

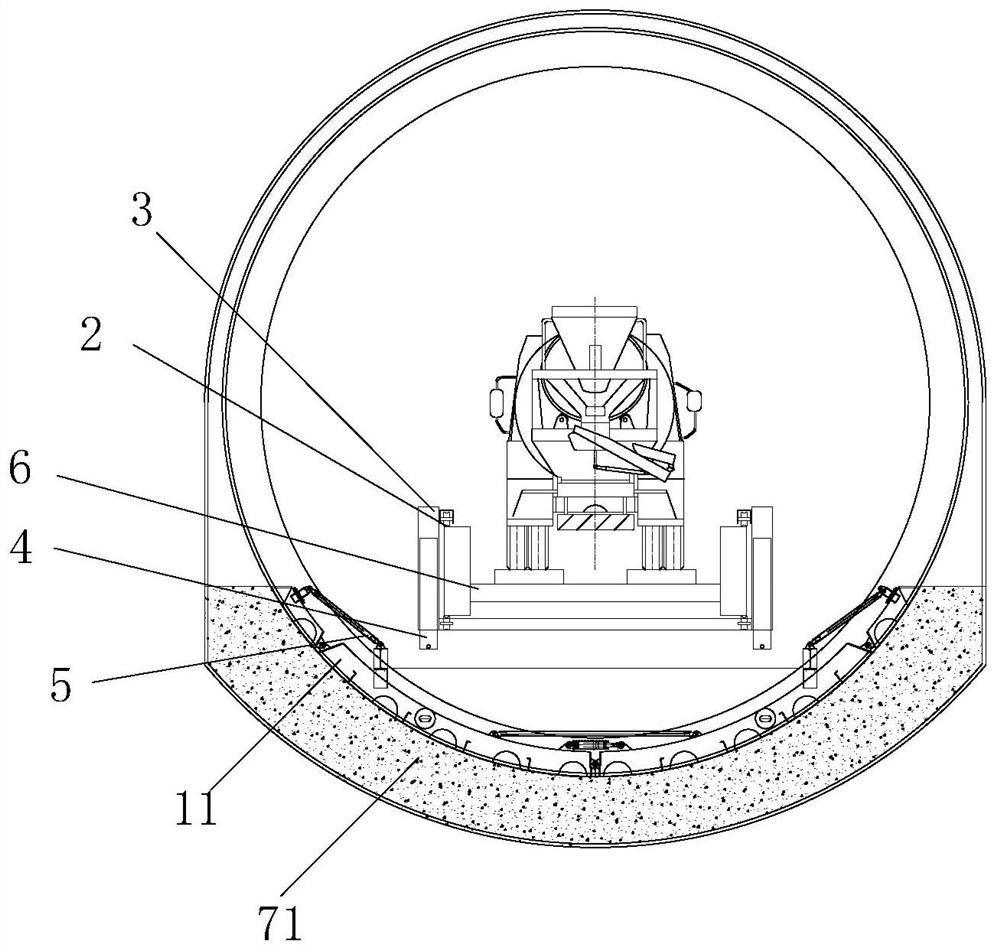

[0027] Figure 1 to Figure 5 It shows an embodiment of the tunnel double-layer inverted arch construction template of the present invention. The tunnel double-layer inverted arch construction template of this embodiment includes a template assembly 1, a track 2, a mobile trolley 3 and a lifting part 4. For the longitudinal arrangement of the arch, the moving trolley 3 is set on the track 2, and the lifting part 4 is set on the moving trolley 3 and connected with the formwork assembly 1. The formwork assembly 1 includes a plurality of arc-shaped sub-boards 11, and two adjacent arc-shaped sub-plates 11 hinged. Wherein, the lifting component 4 may be, for example, a common hydraulic cylinder, a lifting device, and the like.

[0028] The tunnel double-layer inverted arch construction formwork is provided with rails 2 and mobile trolley 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com