Shaft end hydraulic band-type brake

A hydraulic and shaft-end technology, applied in the direction of shock absorbers, hoisting devices, mechanical equipment, etc., can solve the problems of short replacement cycle, poor heat dissipation performance, fast wear, etc., and achieve the effect of simple structure and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

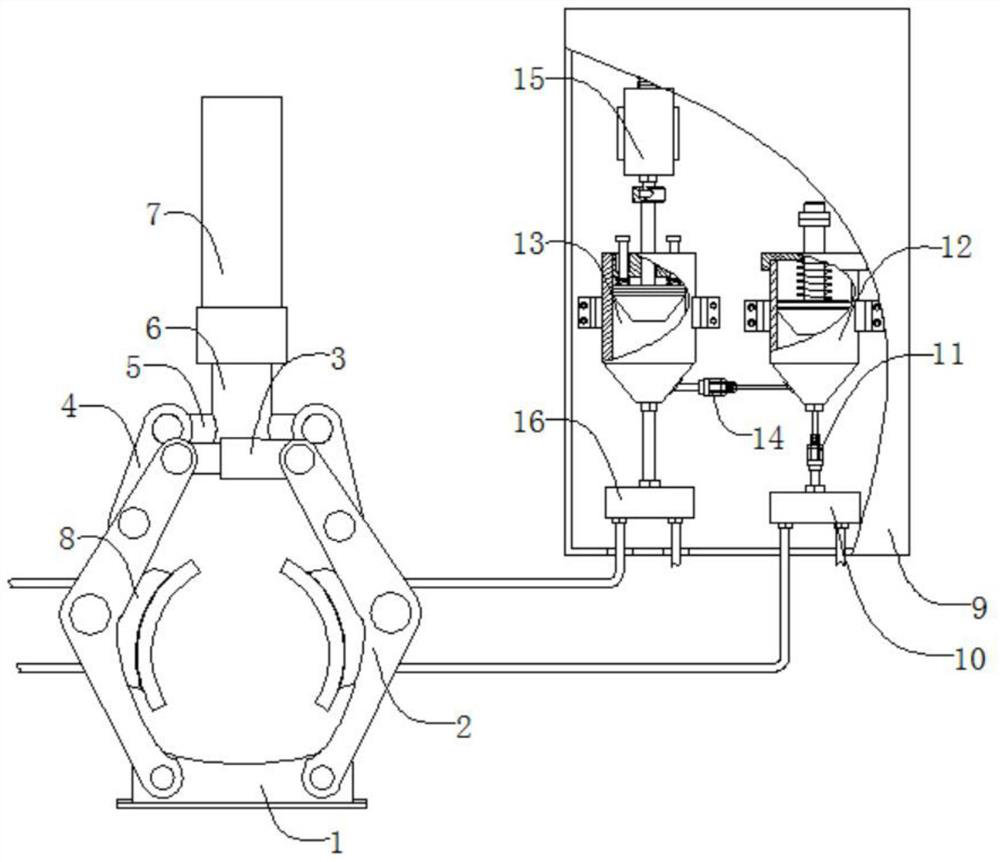

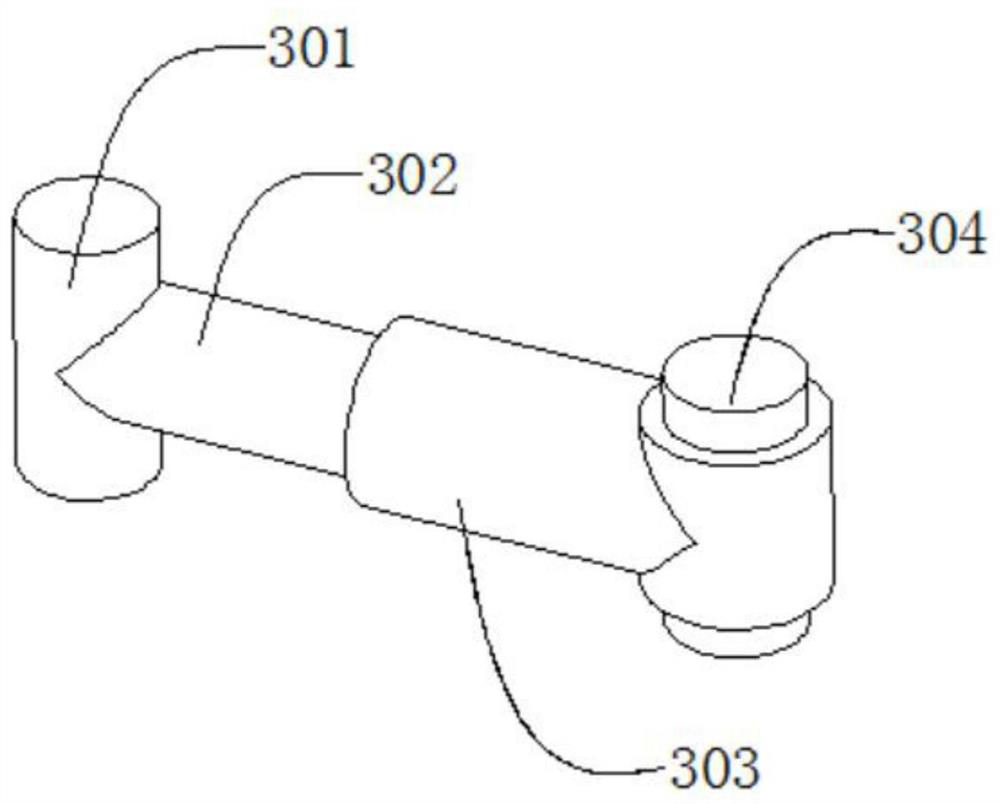

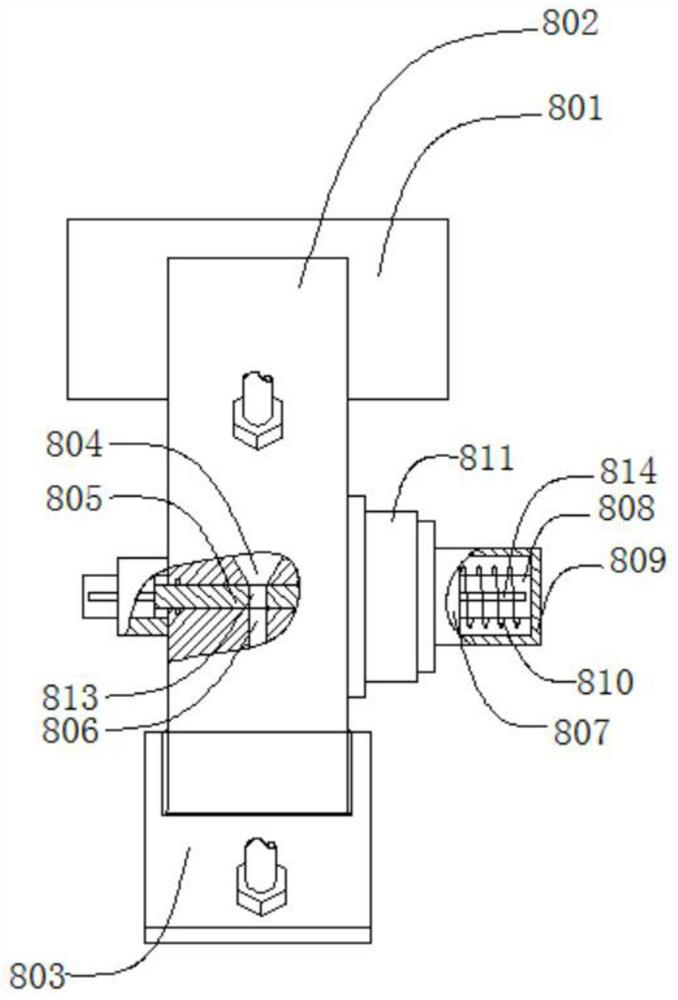

[0020] Such as Figure 1 to Figure 5As shown, an elevator brake device includes a base 1, a support frame 2, a guide mechanism 3, a pressure rod 4, a final shaft 5, a push sleeve 6, an oil cylinder 7, a brake mechanism 8, a housing 9, and a first liquid distribution block 10 , the first one-way valve 11, the buffer mechanism 12, the extrusion mechanism 13, the second one-way valve 14, the long-stroke electromagnet 15, the second liquid-distributing block 16, the number of the support frame 2 is 2 pieces, along the base The left and right directions of 1 are symmetrically arranged, and the guide mechanism 3 is located between two symmetrically arranged support frames 2, and the described guide mechanism 3 is respectively connected to the two symmetrically arranged support frames 2 with clearance fit, and the described support frame 2 is also provided with a pressure rod 4, the pressure rod 4 is connected to the support frame 2 with clearance fit, the pressure shaft 5 is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com