Coal slime drying device and method

A drying device and coal slime technology, which is applied in the direction of drying gas arrangement, drying solid materials, non-progressive dryers, etc., can solve the problems of high cost, high energy consumption and poor effect, and achieve convenient operation and low operating cost. Low, reduce the effect of difficult connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

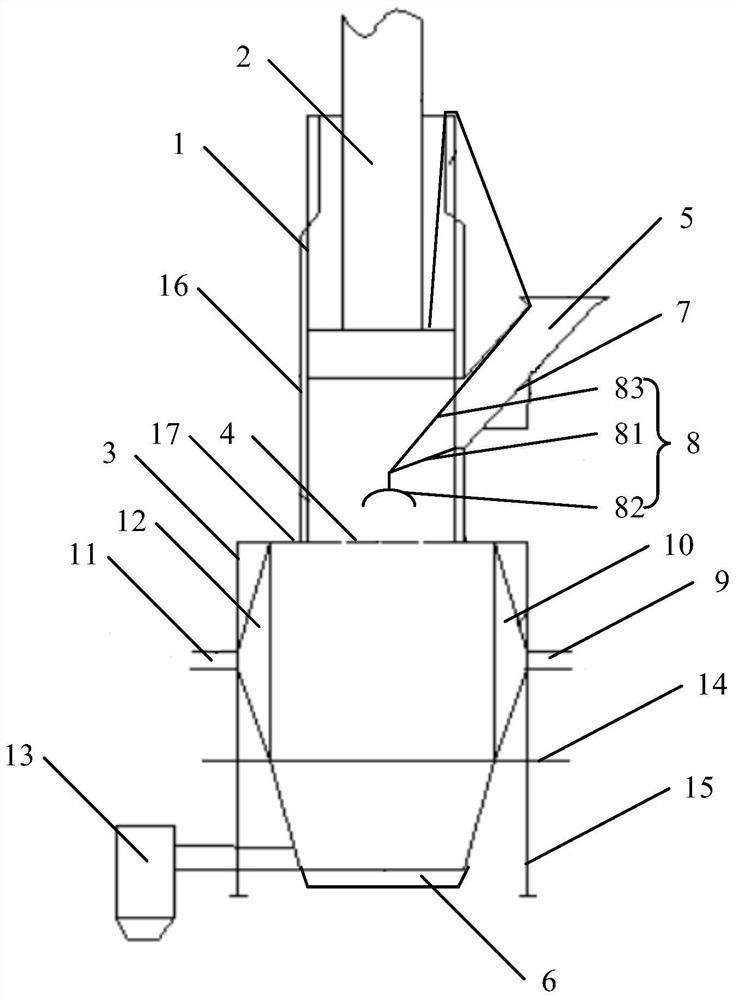

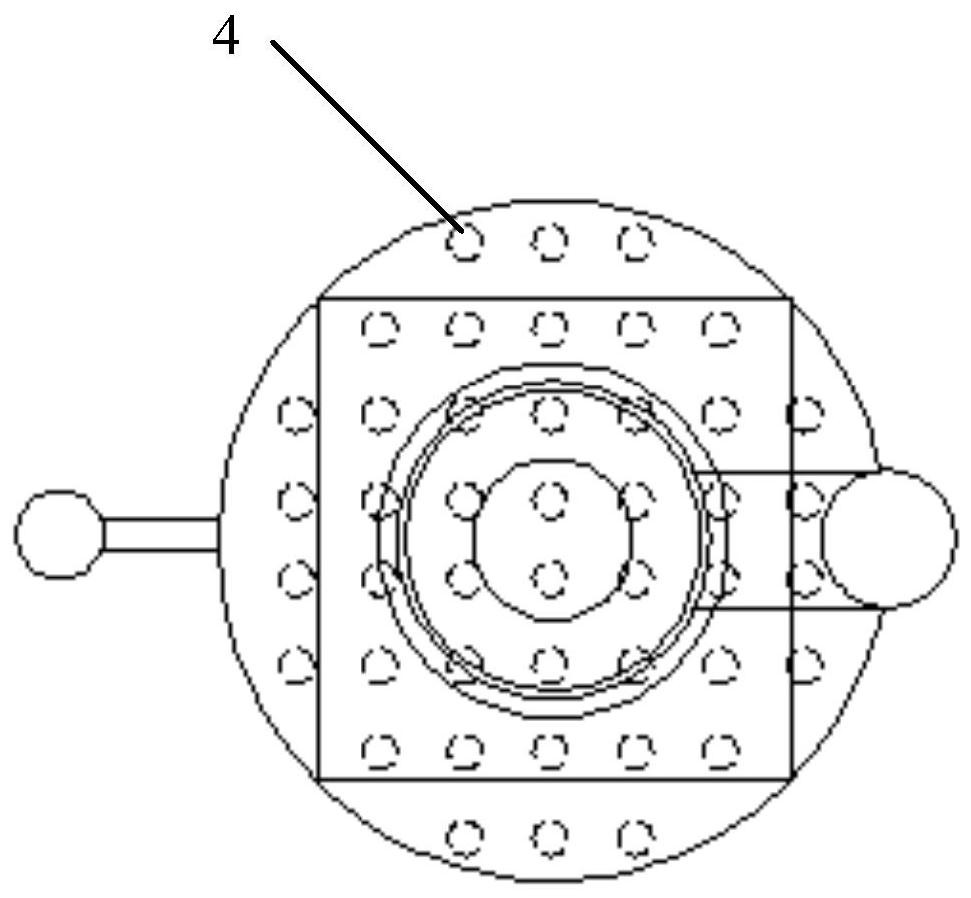

[0063] This embodiment provides a drying device for making slime strips, see Figure 1 to Figure 2 , comprising an extruding assembly, a drying assembly located below the extruding assembly, and a sliver-making orifice 4 between the extruding assembly and the drying assembly, wherein the extruding assembly includes an extruding cylinder 1 and a piston located in the extruding cylinder 1 2. The drying assembly includes a drying cylinder 3 and an air supply unit for supplying dry gas to the drying cylinder 3. The space between the piston 2 and the sliver orifice 4 in the extrusion cylinder 1 is an extrusion cavity, and the inside of the drying cylinder 3 is The drying chamber and the extrusion chamber are connected to the feed pipe 5, and the drying cylinder 3 is connected to the discharge pipe 6; that is to say, along the vertical direction, the piston 2, the extrusion chamber, the sliver orifice 4, and the drying chamber are arranged in sequence.

[0064] It should be noted th...

Embodiment 2

[0088] The present embodiment provides a kind of coal slime drying method, comprises the following steps:

[0089] Step 1: Feed of Slime

[0090] Open the feeding pipe, and the coal slime enters the extrusion chamber from the feeding pipe. When the coal slime in the extrusion chamber reaches a certain thickness, close the feeding pipe;

[0091] Step 2: Compression cutting and extrusion drying of slime

[0092] When the piston is opened, the piston moves to the direction of the orifice plate, the volume of the extrusion chamber gradually decreases, the piston squeezes the slime, and under the action of pressure, the coal slime passes through the sliver hole of the orifice plate to complete the compression cutting of the slime and extruding and drying to obtain slime strips, and the piston resets;

[0093] Step 3: Drying of slime strips

[0094] The slime strips formed by extrusion are hung vertically under the strip-making orifice and in the drying chamber. The air supply un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com