Molecular pump unit and vacuum system leak detection method

A technology of vacuum system and molecular pump, which is applied in the direction of liquid tightness measurement, pump, and pump control by using liquid/vacuum degree, which can solve the problems of complicated leak detection process and achieve the effect of simple and fast self-test and inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

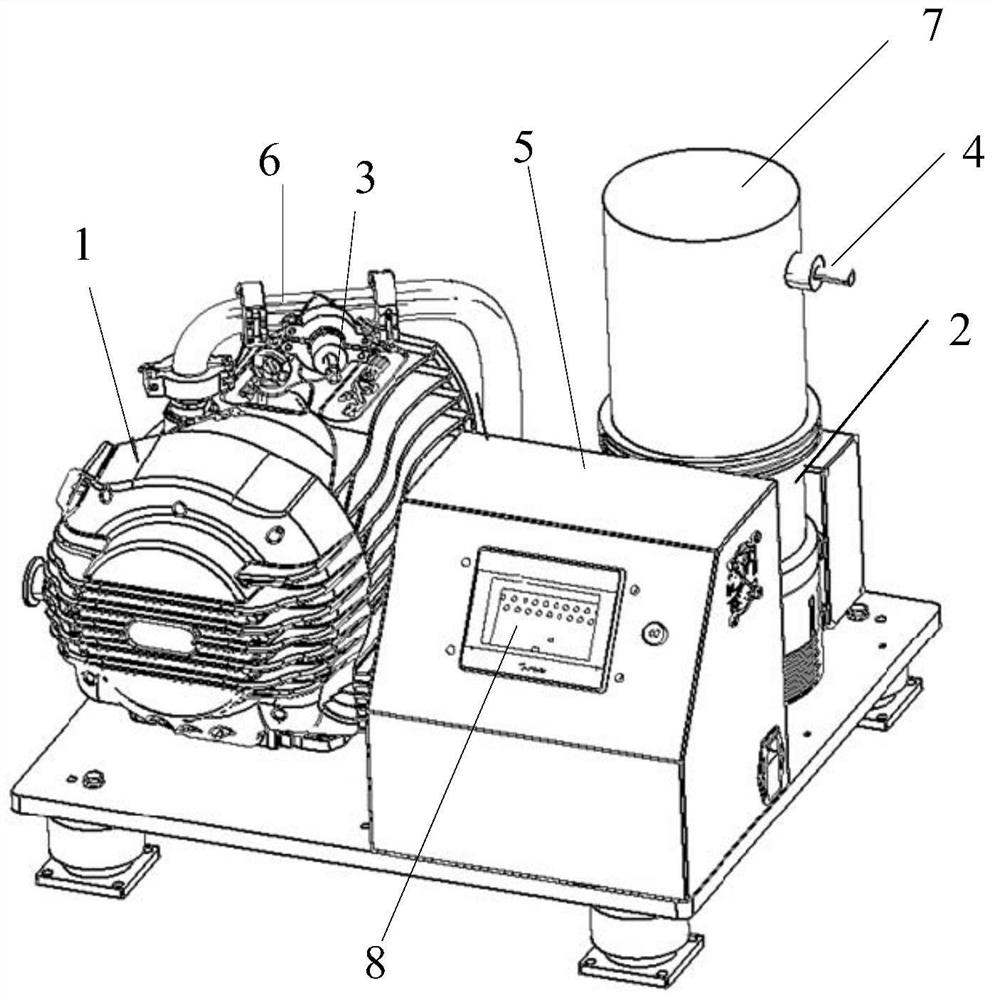

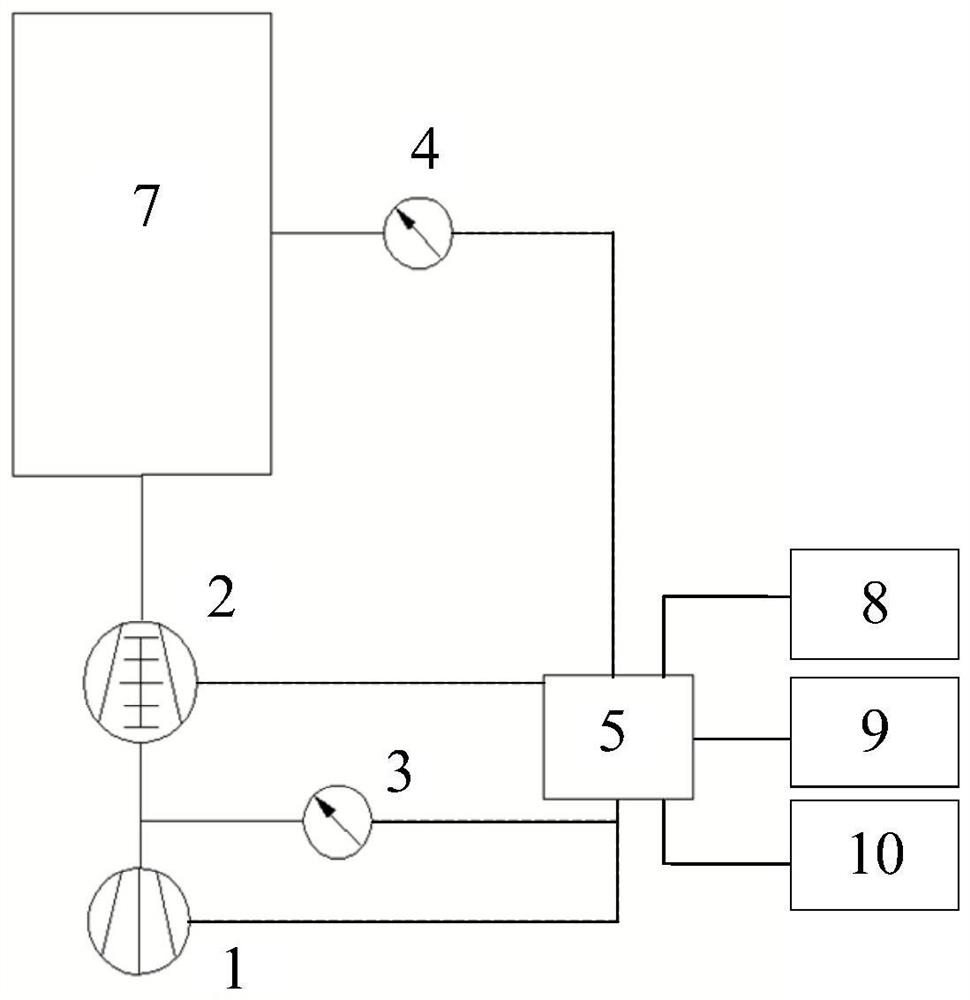

[0023] The embodiment of the present invention provides a molecular pump unit, such as figure 1 and figure 2 As shown, it includes a backing pump 1 and a molecular pump 2, and also includes: a backing vacuum gauge 3, a high vacuum gauge 4, and a unit controller 5. Specifically, the backing pump may be an oil-sealed mechanical vacuum pump.

[0024] The backing vacuum gauge 3 is arranged on the vacuum pipeline 6 for measuring the backing pressure after the backing pump 1 is turned on.

[0025] In the embodiment of the present invention, the vacuum pipeline 6 is connected to the backing pump 1 and the backing vacuum gauge 3 respectively. The internal pressure can obtain the fore-stage pressure after the fore-stage pump 1 is turned on, so that the air leakage condition of the vacuum system where the molecular pump unit is located can be indirectly reflected through the fore-stage pressure.

[0026] In a specific embodiment, if the foreline pump 1 is turned on, the pressure of o...

Embodiment 2

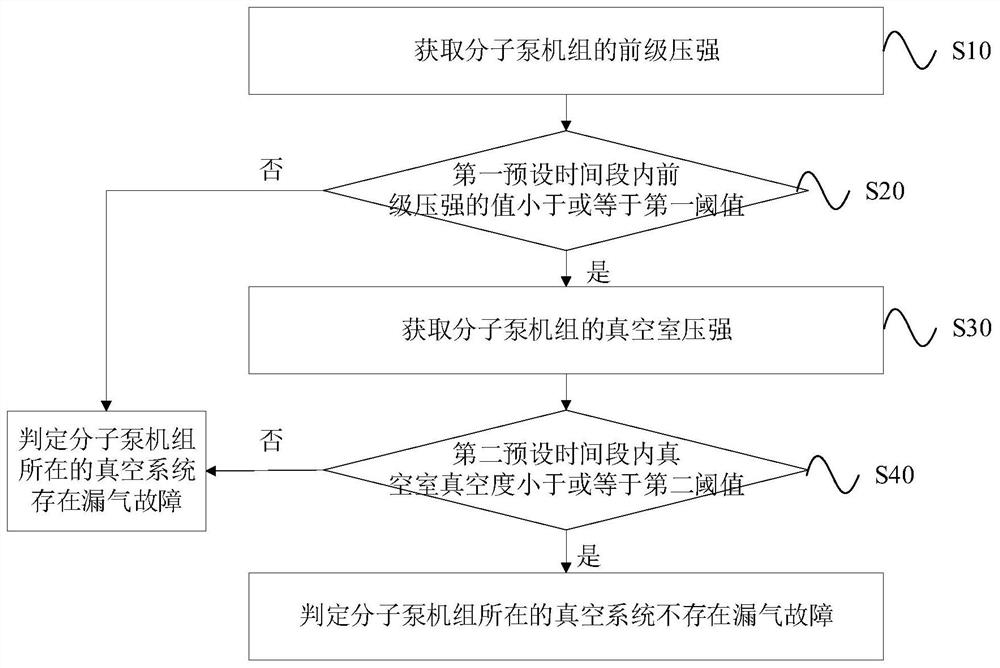

[0039] The embodiment of the present invention provides a vacuum system leak detection method, which is suitable for the molecular pump unit provided in the above embodiment 1, such as image 3 As shown, the leak detection method mainly includes:

[0040] Step S10: Obtain the backing pressure of the molecular pump unit. In practical applications, the backing pump 1 can be turned on first, and the backing vacuum gauge 3 is used to measure the pressure of the vacuum pipeline 6 to obtain the backing pressure.

[0041] Step S20: judging whether the value of the pre-stage pressure within the first preset time period is less than or equal to the first threshold. In a specific embodiment, the first threshold can be adjusted according to the actual working conditions. In the embodiment of the present invention, the value of the first threshold can be set to 10Pa, and the ideal time for the pressure in the vacuum line 6 to reach 10Pa is the same as The parameters of the backing pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com