TPU reinforced wiredrawing air cushion and production process thereof

A production process and wire drawing technology, applied in the direction of layered products, synthetic resin layered products, coatings, etc., can solve the problems of poor heat sealing performance, poor anti-aging performance, high production cost, etc., and achieve pressure bearing capacity and structural stability Enhanced durability, improved wear resistance and anti-aging properties, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

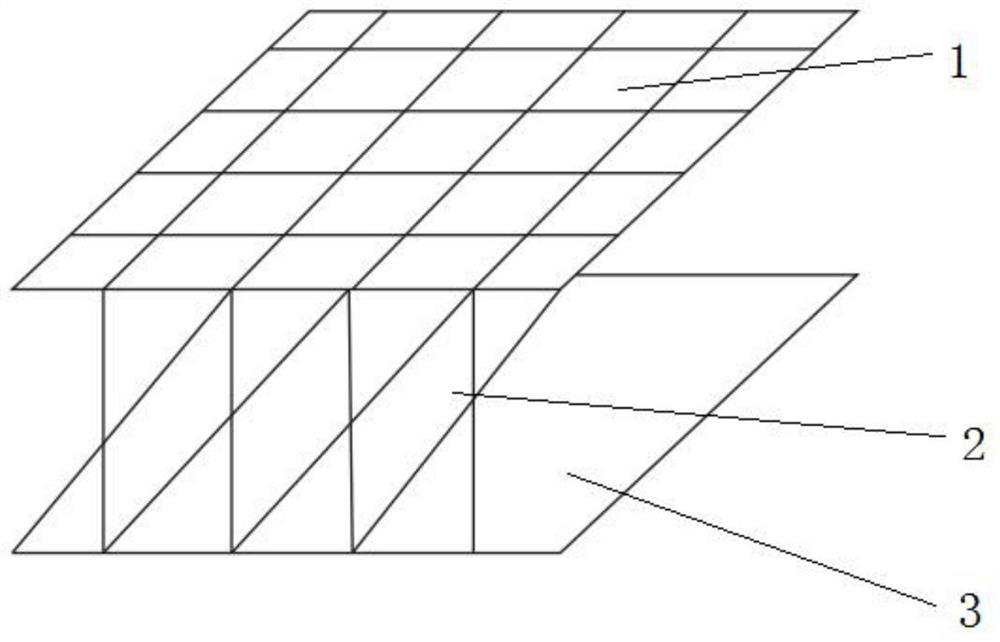

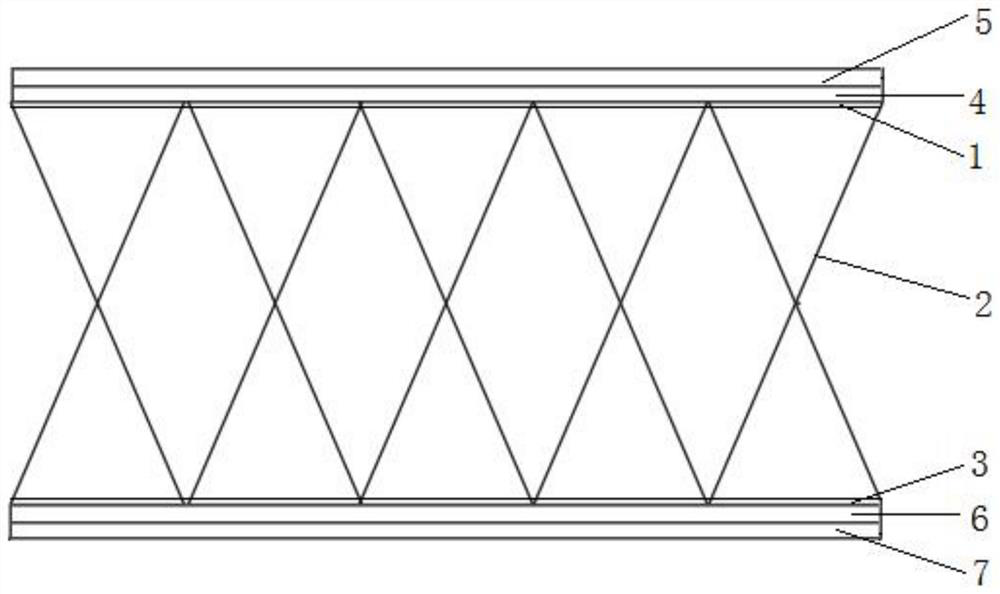

[0022] Such as image 3 A TPU reinforced drawing air cushion shown includes an upper mesh cloth 1 and a lower mesh cloth 3, and it also includes a polyethylene fiber drawing layer 2 between the upper mesh cloth 1 and the lower mesh cloth 3, and the upper mesh cloth 1 , The lower grid cloth 3 is connected through the polyethylene fiber drawing layer 2;

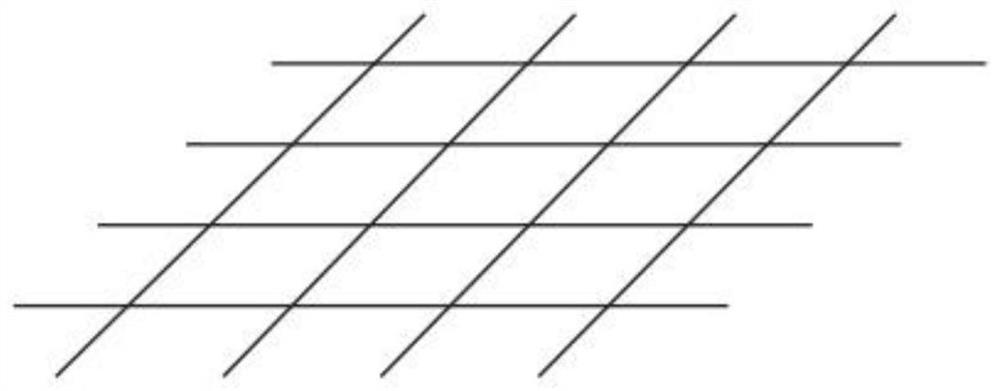

[0023] Composed of upper grid cloth 1, lower grid cloth 3 and polyethylene fiber layer 2 figure 2 In the space cloth shown, polyethylene fiber is used as the middle drawing layer, and the advantages of high strength, low density and good insulation of polyethylene fiber are fully utilized to greatly improve the performance of the drawing air cushion; for the middle polyethylene fiber drawing Layer 2, which consists of several X-shaped wire drawing units arranged vertically and horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com