Method for automatically adjusting roller and belt of dry skiing machine

An automatic adjustment and ski machine technology, applied in the direction of conveyor, transportation and packaging, etc., can solve the problems of belt deviation, operator loss, and influence on training personnel training, so as to achieve consistent tension, save maintenance time, and more The effect of training time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

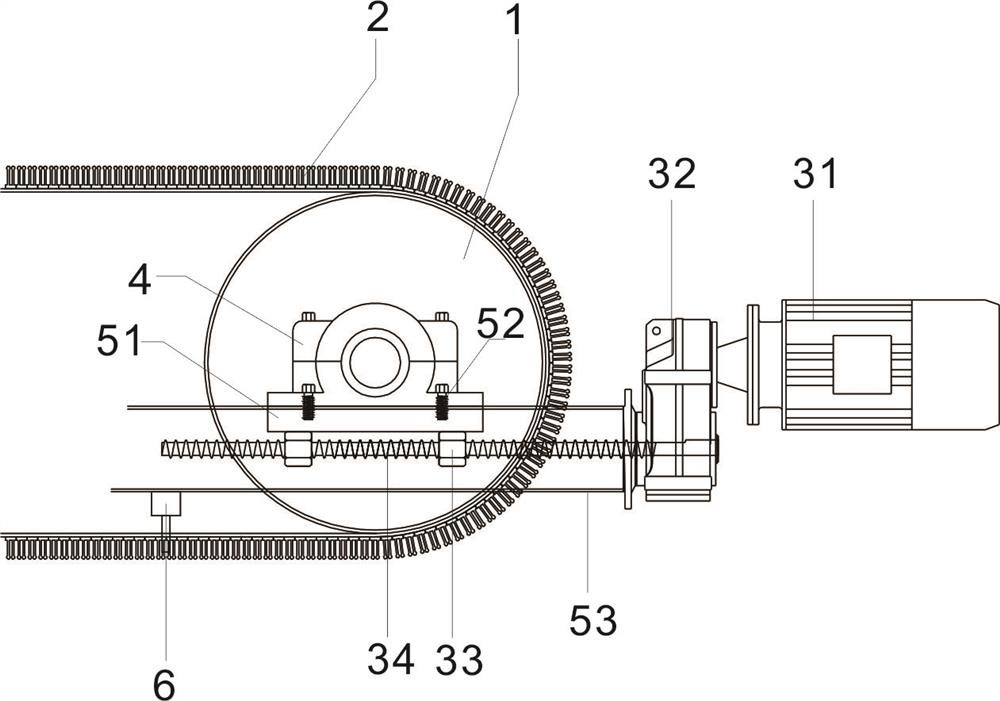

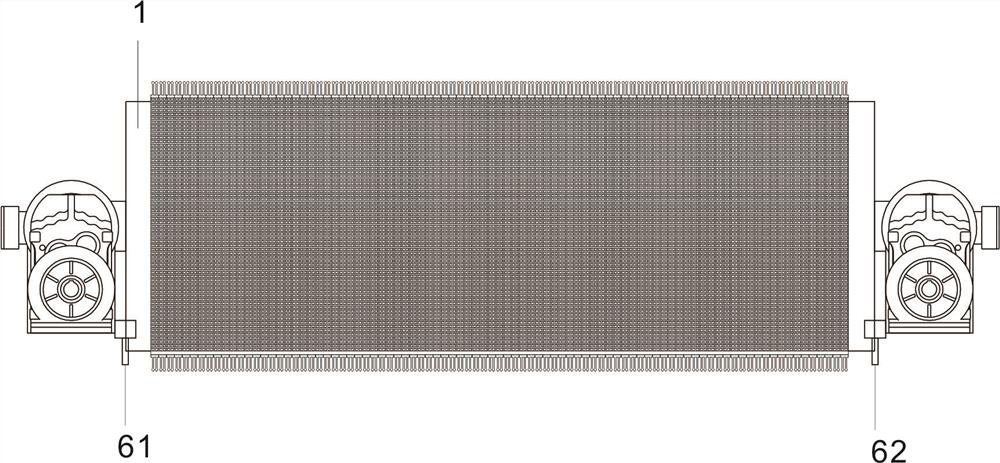

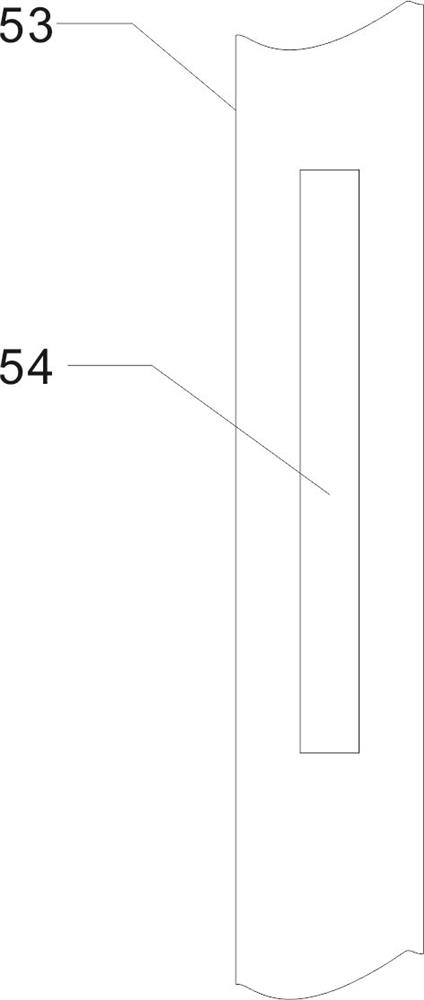

[0040] Such as figure 2 As shown, under normal circumstances, when the belt 2 rolls on the drum 1, there is a certain distance from the frame, and the sensors 6 on both sides of the belt on the frame can detect the belt. Once the sensor 6 detects the belt When shifting to the left or right, the controller will control the motor to rotate. Since the two ends of the drum 1 are equipped with sliding devices and transmission devices, the controller will analyze the signal transmitted by the sensor 6 to determine whether it is only Whether to start the motor on one side, or both sides need to be started, so as to correct the tension of the roller and stabilize the rotation of the belt.

[0041] Embodiment one

[0042] Such as figure 2 As shown, there are two sensors, which are symmetrically arranged on both sides of the belt 2, and are divided into left sensor 61 and right sensor 62. Before starting up, preset sensor 6 in the controller to detect when the belt does not deviate....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com