Emergency stop device and emergency stop method for searching falling objects during working of large crusher

A pulverizer and article technology, applied in furnace safety devices, petroleum industry, coke ovens, etc., can solve problems such as reducing the probability of hammer heads or hammer cakes being found, poor reliability, and jamming, and achieve easy on-site jobs. operation, resolving extremely poor reliability, reducing the effect of severe damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

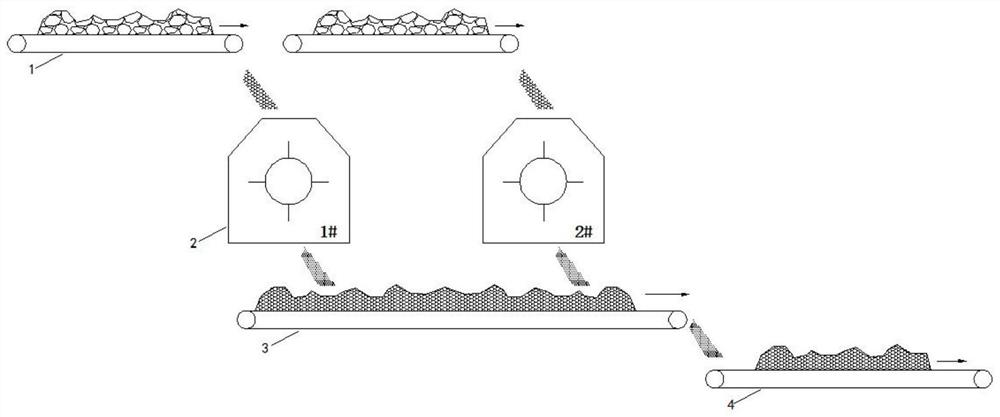

Method used

Image

Examples

Embodiment Construction

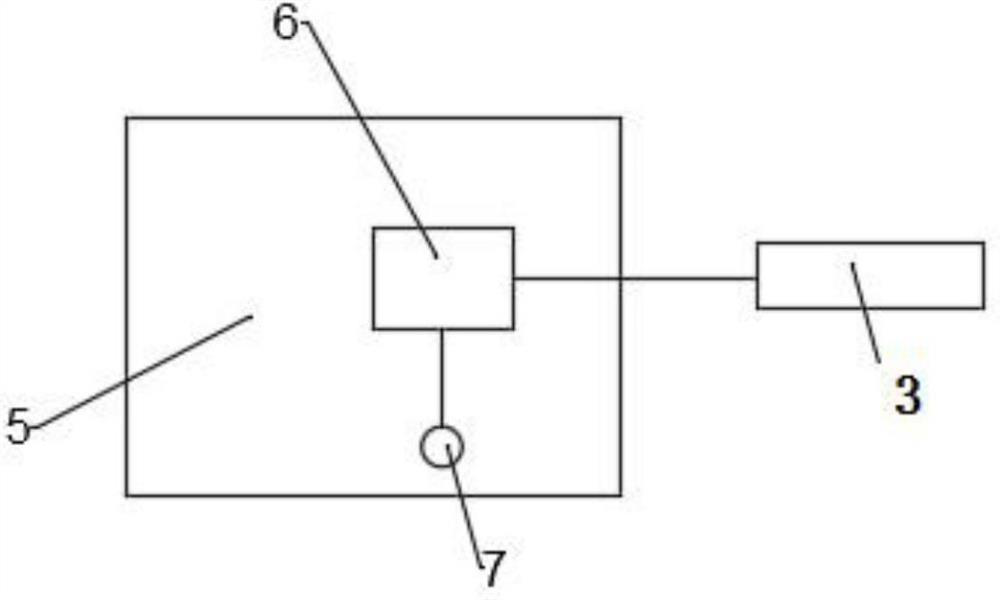

[0026] Such as figure 2 As shown, an emergency stop device for finding items dropped when a large pulverizer is working, includes an operating console 5 arranged in the operating room, the console 5 includes a controller 6, and the controller 6 communicates with each drive of the pulverizer. The device is electrically connected to control the working state of the pulverizer; the controller 6 of the console 5 is also electrically connected to an emergency stop button arranged on the console 57, and the emergency stop button 7 is used to Under the stopped state, the working state of the first main belt conveyor 3 downstream of the pulverizer can be stopped urgently.

[0027] The first main belt conveyor 3 downstream of the pulverizer and all other main belt processes downstream of the pulverizer are electrically connected with the controller 6 of the operating platform for interlocking control. The emergency stop button 7 is bright red, and the emergency stop button 7 is semic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com