UHPC-NC mixed box girder, large-span rigid frame bridge and construction method of large-span rigid frame bridge

A technology of UHPC-NC and mixing box, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as cracking and deflection, achieve good durability, reduce creep effects, reduce deflection and cracking risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

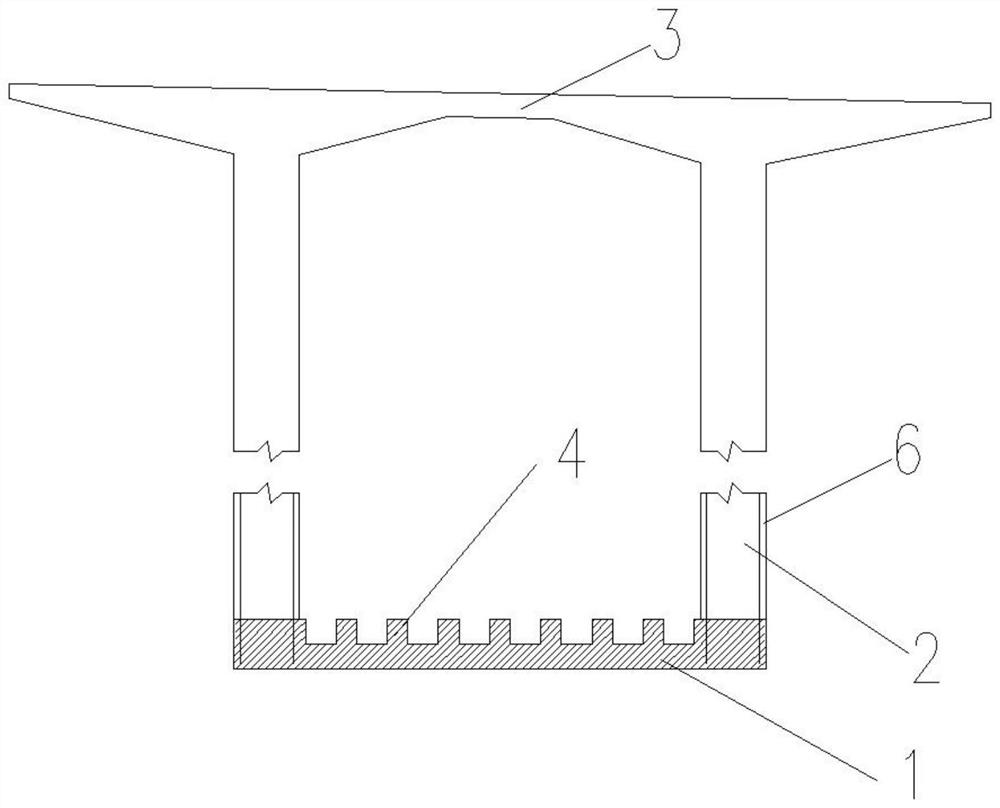

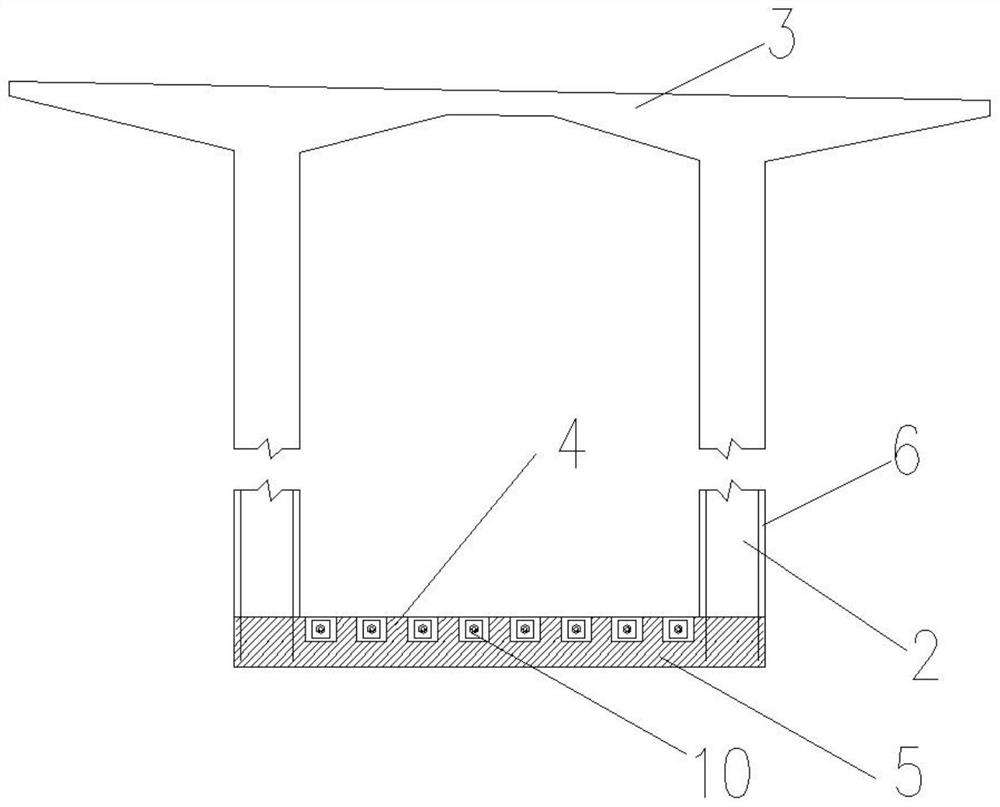

[0044] like Figure 2-Figure 3 As shown, the UHPC-NC hybrid box girder used for long-span rigid-frame bridges in this embodiment includes UHPC ribbed bottom plate 1, NC web 2 and NC top plate 3, and UHPC ribbed bottom plate 1 passes through NC web 2 and NC The top plate 3 is fixedly connected as a whole.

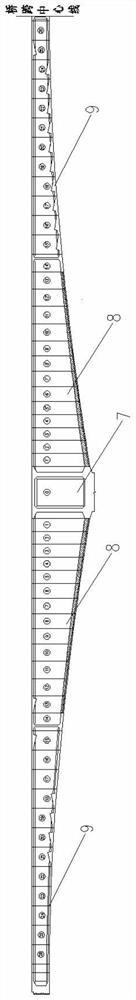

[0045] In this embodiment, the UHPC ribbed base plate 1 is provided with multiple longitudinal ribs 4 and two transverse ribs 5, and the multiple longitudinal ribs 4 are evenly arranged on the UHPC ribbed base plate 1 along the longitudinal bridge direction, and the two transverse ribs 5 are respectively It is arranged on both sides of the longitudinal bridge of the UHPC ribbed bottom plate 1 along the transverse bridge. In this embodiment, UHPC ribbed floor 1 has a width of 6m across the bridge and a thickness of 30cm, on which longitudinal ribs 4 are arranged. Sections 1#-13#, 1#'-13'# transition from 90cm to 30cm according to a parabola. The transverse rib 5 is equal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com