Offshore spilled oil recovery device

A recovery device and technology for oil spills at sea, applied in general water supply conservation, water conservancy projects, and open-air water surface cleaning, etc., can solve the problems of slow recovery speed and limited application environment, and achieve fast recovery speed, wide application environment, continuous The effect of strong work ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

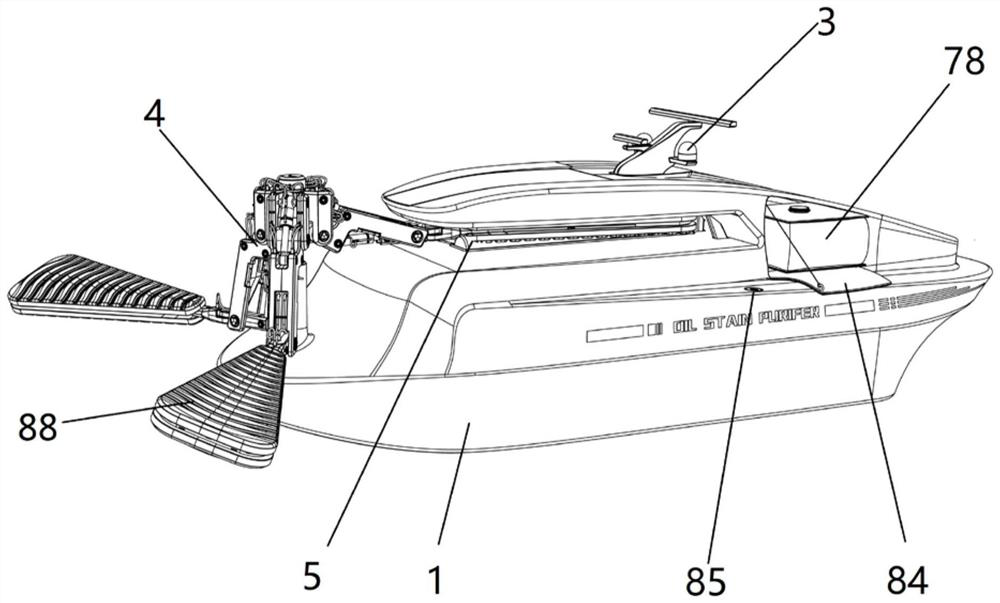

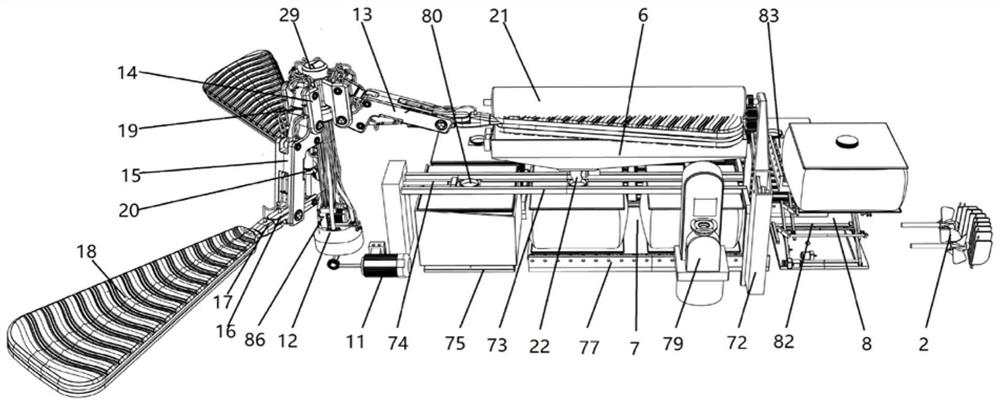

[0045] Such as Figure 1-Figure 9 As shown, a marine oil spill recovery device includes a hull 1 and a control unit located on the hull 1, a drive unit 2, a monitoring and navigation unit 3, an oil suction unit 4, an oil squeeze unit 5, an oil storage unit 6, and an oil packaging unit 7 and oil product transfer unit 8.

[0046] The control unit is connected with the drive unit 2, the monitoring and navigation unit 3, the oil suction unit 4, the oil squeeze unit 5, the oil storage unit 6, the oil product dispensing unit 7 and the oil product transfer unit 8, and the existing controller is used to control each unit The action of driving unit 2 is located at the stern, used to drive the hull 1 to run on the sea surface, including engine (not shown in the hull), propeller 89 and split rudder 90; monitoring and navigation unit 3 is composed of monitoring detector and navigation radar , located on the top of the hull 1, used to guide the hull 1 to the oil spill area and plan the oi...

Embodiment 2

[0055] Such as Figure 9-Figure 11 As shown, the difference between the second embodiment and the first embodiment is that the structures or positions of the oil suction unit 4 , the oil squeeze unit 5 and the oil storage unit 6 are different. details as follows:

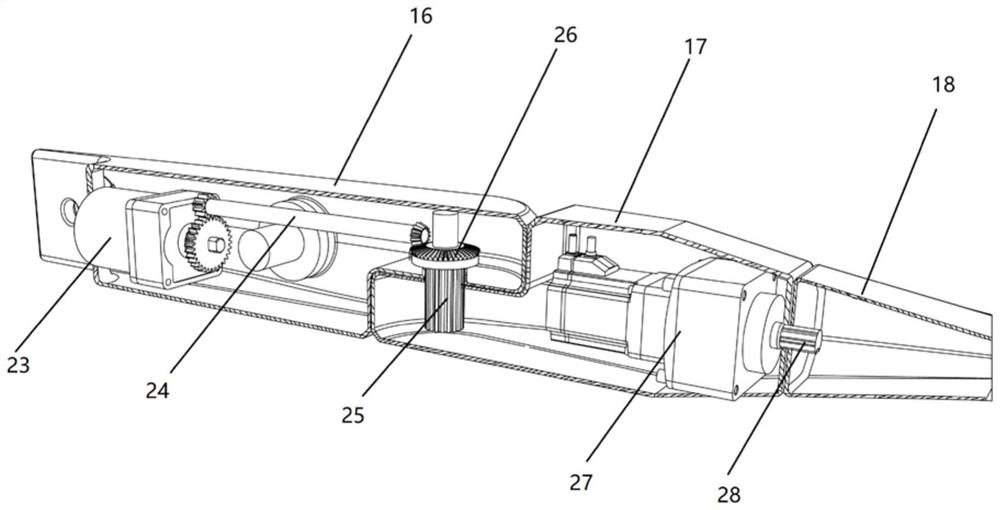

[0056] The oil suction unit 4 includes a lifting support column 48 , a second support frame 49 , a fifth motor 50 , a horizontal central shaft (not shown in the figure), a second support shell 52 and two oil suction plates 53 . The lifting support column 48 is arranged on the hull 1; the fifth motor 50 is installed on the lifting support column 48 through the second support frame 49, and its output is connected with the horizontal central axis to drive the horizontal central axis to rotate; the oil-absorbing plate 53 includes a support frame 54 and oil-absorbing sponge 88; the support frame 54 includes a rectangular support base plate 55 and four support side plates that are respectively connected with the four sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com