Flood prevention device for transformer substation

A technology for flood control devices and substations, applied in water supply devices, grease/oily substance/floating matter removal devices, water/sludge/sewage treatment, etc. It can solve problems such as water pump damage, easy suction of debris, and difficulty in handling. Achieve the effect of convenient transportation and ensure pumping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

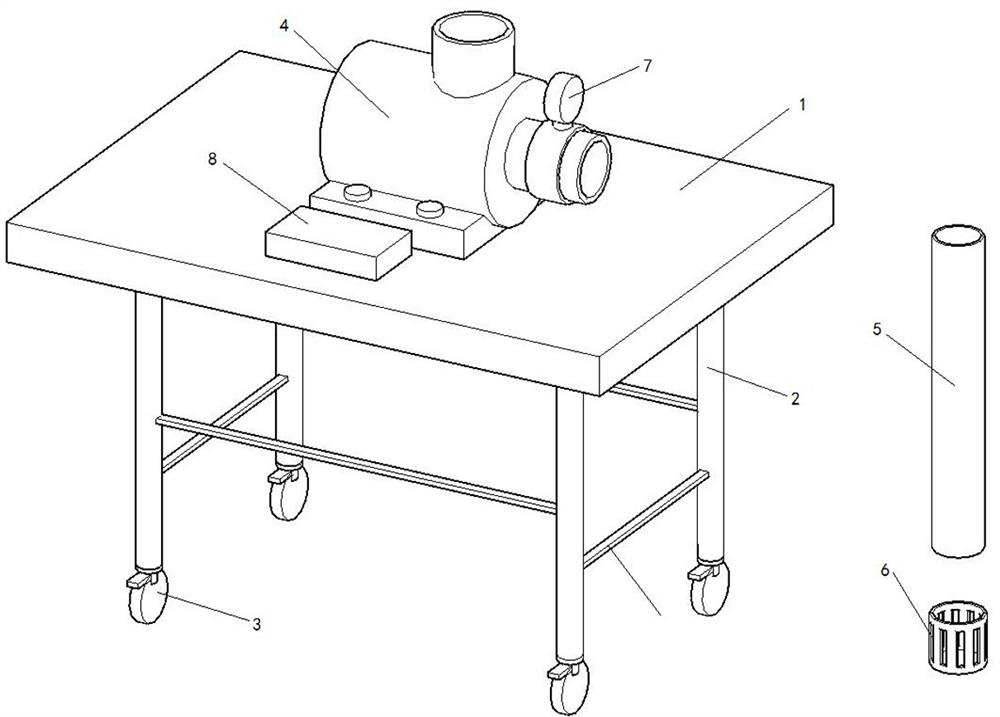

[0028] Such as figure 1 Shown is the first embodiment of the present invention, the vehicle frame includes a top plate 1 and four legs 2 welded and fixed below the top plate 1, and a universal brake wheel 3 is installed on the bottom end surface of the legs 2;

[0029] The suction pump 4 is fixedly installed on the top plate 1 by bolts. The suction pump 4 is provided with a suction port and a water outlet. It is a shell-shaped structure with hollow sides, and the inner peripheral surface of the top of the filter cover 6 is fixed on the outer peripheral surface of the bottom end of the suction pipe 5 by means of glue or the like;

[0030] Flow meter 7, flow meter 7 is installed on the suction port of water pump 4, is used for monitoring the water flow rate that draws out;

[0031] PLC8 is installed on the top plate 1, the flow meter 7 is electrically connected to the input end of PLC8, and the motor of the water pump 4 is electrically connected to the output end of PLC8.

[0...

Embodiment 2

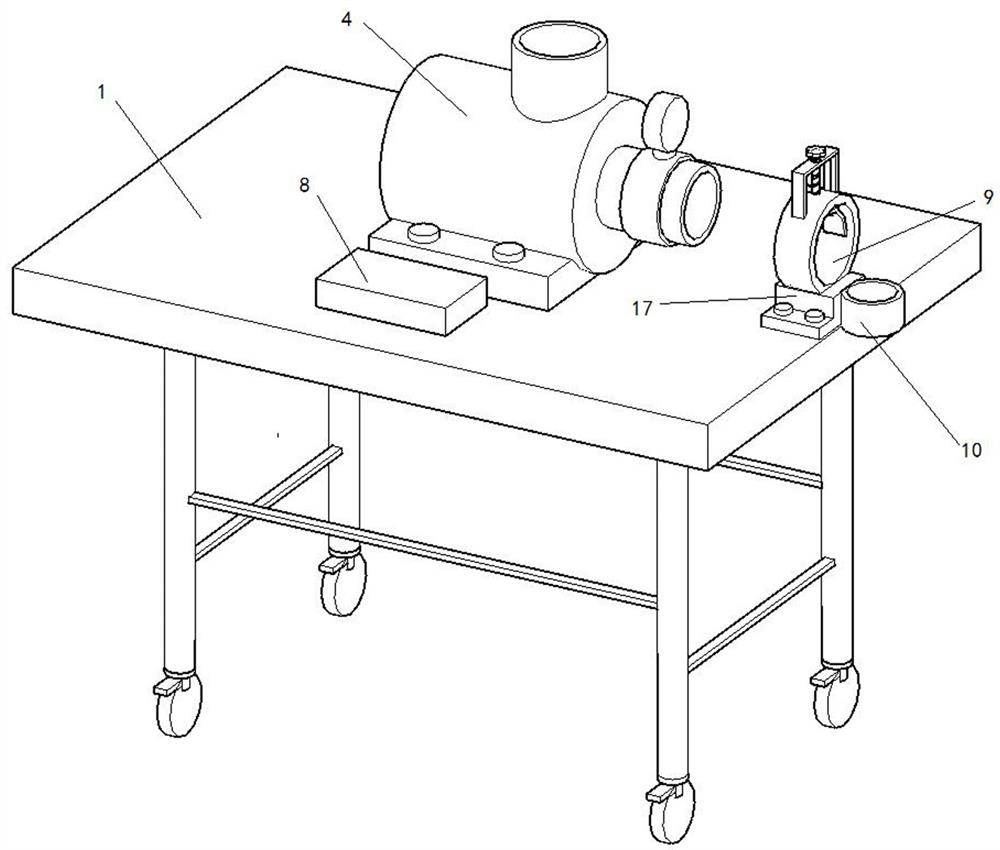

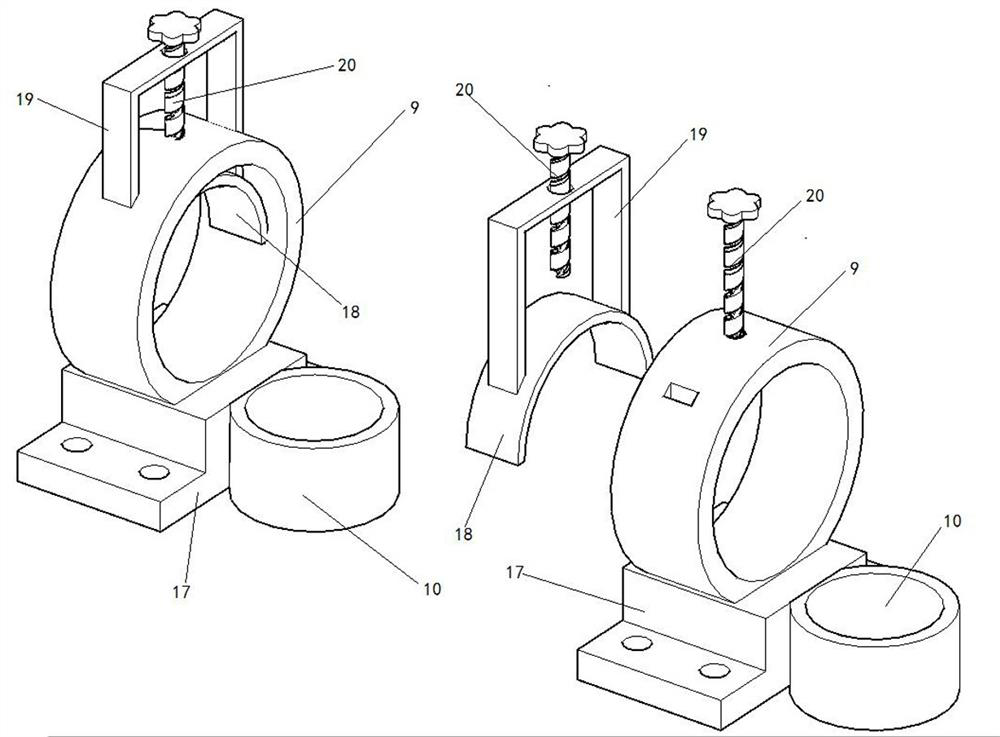

[0034] Such as Figure 2-4 Shown is a schematic structural diagram of the second embodiment of the present invention. The difference between this embodiment and the first embodiment is that the side of the top plate 1 is provided with a limit assembly that restricts the bottom end of the suction pipe 5 to be perpendicular to the ground, and the limit assembly includes a limit ring The first 9 and the limit ring two 10, the limit ring one 9 and the limit ring two 10 are both round shell-shaped structures with openings at both ends, and the limit ring one 9 is fixedly installed on the top surface of the fixed frame 17 by means of glue or the like , the limit ring two 10 is fixedly installed on the side of the fixed frame 17 by means of viscose, etc., the fixed frame 17 is fixedly installed on the top plate 1 by bolts, the limit ring two 10 protrudes from the top plate 1 completely, and one end of the suction pipe 5 is connected to the top plate 1. After the water outlet is conne...

Embodiment 3

[0037] Such as Figure 4-5Shown is the third embodiment of the present invention, the difference between the present embodiment and the first embodiment is that the top plate 1 is provided with a drive assembly that drives the limit ring one 9 and the limit ring two 10 to be close to or away from the side of the top plate 1, and drives The assembly includes an electric push rod 12, and the accommodating cavity 13 for accommodating the electric push rod 12 is machined on the top plate 1 through a lathe. The longitudinal section is larger than the longitudinal section of the accommodating cavity 13, and the fixing plate 15 is detachably connected to the top plate 1 by bolts. The end of the telescopic end of the electric push rod 12 is fixedly connected to the push plate 14 matched with the accommodating cavity 13 through glue, the limit ring one 9 and the limit ring two 10 are arranged on the push plate 14 and are detachably connected with the push plate 14, The connection meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com