Closely-spliced one-way laminated slab free of bar extending out of plate end and construction method of closely-spliced one-way laminated slab

A technology of connecting slabs and laminated slabs, which is applied to floors, structural elements, building components, etc., can solve the problems of discontinuous steel bars at the bottom, poor waterproof effect, and the existence of post-casting belts, so as to improve the waterproof effect and the continuous steel bars under stress , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

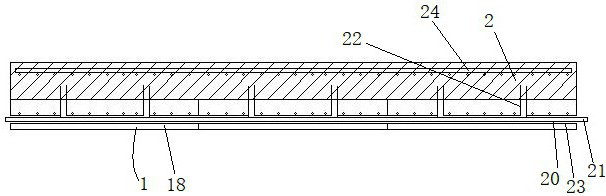

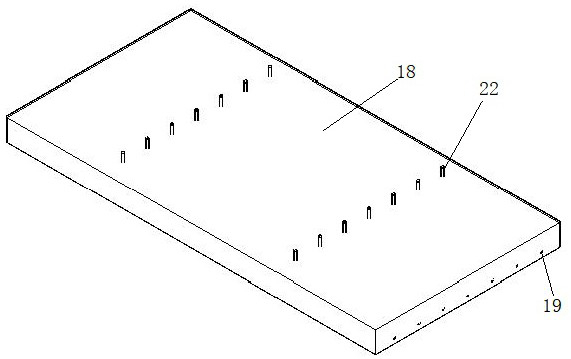

[0033] Embodiment one, see figure 1 and figure 2 The invention discloses a one-way laminated slab with no ribs at the end of the close-fitting connecting plate, comprising a prefabricated bottom layer 1 and a cast-in-place surface layer 2 on the prefabricated bottom layer. Both the precast ground floor and the cast-in-place surface are concrete structures. The prefabricated bottom layer is composed of several prefabricated concrete panels 18 spliced together. The concrete prefabricated slabs are provided with a number of steel bar channels 19 extending along the distribution direction of the concrete precast slabs, and the steel bar channels between adjacent concrete precast slabs are sealed and butted together one by one to form steel bar through holes 20 . A bottom stressed steel bar 21 is pierced through the steel bar passing hole. The two ends of the reinforced steel bars at the bottom are fixed on the two prefabricated concrete slabs at the outermost edge. A number...

Embodiment 2

[0035] Embodiment two, the difference with embodiment one is:

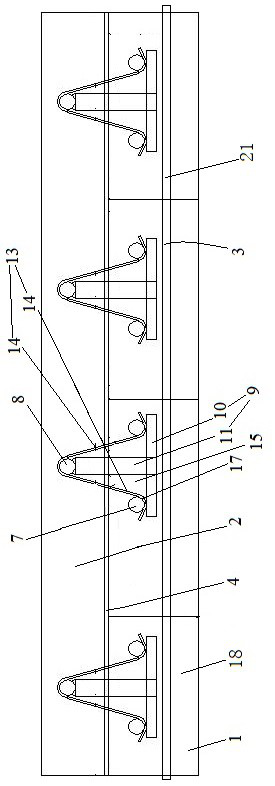

[0036] see image 3 and Figure 4 , also includes a number of lattice reinforcement groups 3 and a waterproof coating layer 4 between the prefabricated bottom layer and the cast-in-place surface layer. The lattice steel bar group includes the lower threaded steel bar 7, the upper threaded steel bar 8 and the steel connecting frame connecting the upper threaded bar and the lower threaded bar together. The lower threaded steel bars are poured in the prefabricated concrete slab, and the upper threaded steel bars are poured in the cast-in-place surface layer. A lattice reinforcement group includes 2 lower rebars and 1 upper rebar, and the upper rebar and the lower rebar are distributed in a triangle. The steel connecting frame includes two end connecting steel frames 9 located at the two ends of the upper threaded steel bar. The end connecting steel frame includes a horizontal steel section 10 and a vertical steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com