Semi-rigid semi-flexible anti-impact tunnel surrounding rock supporting structure under seismic zone and construction method thereof

A technology of surrounding rock support and construction method, which is applied in the direction of tunnels, tunnel linings, underground chambers, etc., can solve problems such as inability to guarantee construction safety, damage to surrounding rock structures in tunnels, and fracture of support structures, and achieve good results. Energy-absorbing effect, ensuring safe construction, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

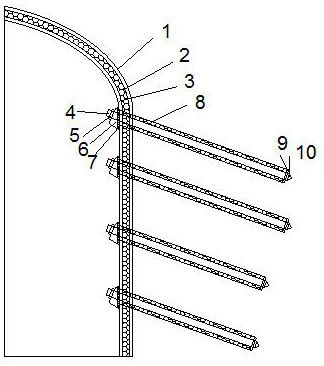

[0026] The present invention is specifically described below in conjunction with accompanying drawing:

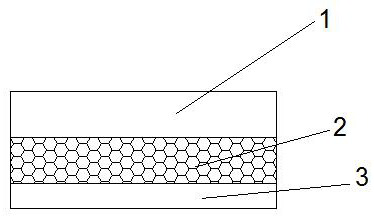

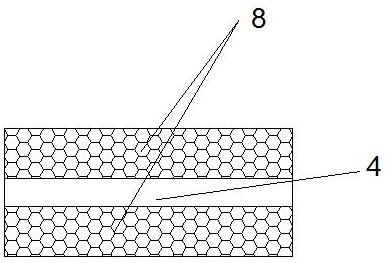

[0027] Surrounding rock support structure and construction method of semi-rigid and semi-flexible impact-resistant tunnel under earthquake zone, consisting of surrounding rock body 1, porous metal wall panel 2, rigid support 3, pull rod 4, anchorage 5, pedestal 6, porous metal pad Plate 7, porous metal sleeve 8, baffle plate 9 and drill bit 10, porous metal wall plate 2 placed outside surrounding rock body 1, rigid support 3 placed outside porous metal wall plate 2, and 8 sets of porous metal sleeves On the pull rod 4, the porous metal backing plate 7 and the pedestal 6 are installed on the pull rod 4, the anchor 5 is placed outside the pedestal 6, the anchor 5 is installed at the end of the pull rod 4, the baffle plate 9 and the drill bit 10 are installed at the bottom of the pull rod 4.

[0028] Excavate the tunnel to 1.6-3.0m, drill the hole obliquely downward toward the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com