Disc brake pad production equipment and method

A technology of disc brake pads and production equipment, which is applied in the direction of mechanical equipment, friction linings, trolley cranes, etc., can solve the problems of large dust in the production environment, high potential safety hazards for personnel, and low production efficiency, and achieve stable production rhythms, The effect of reducing staffing and saving money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

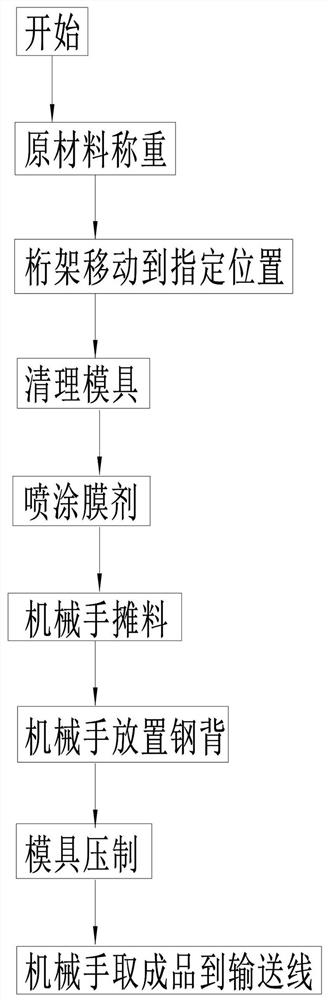

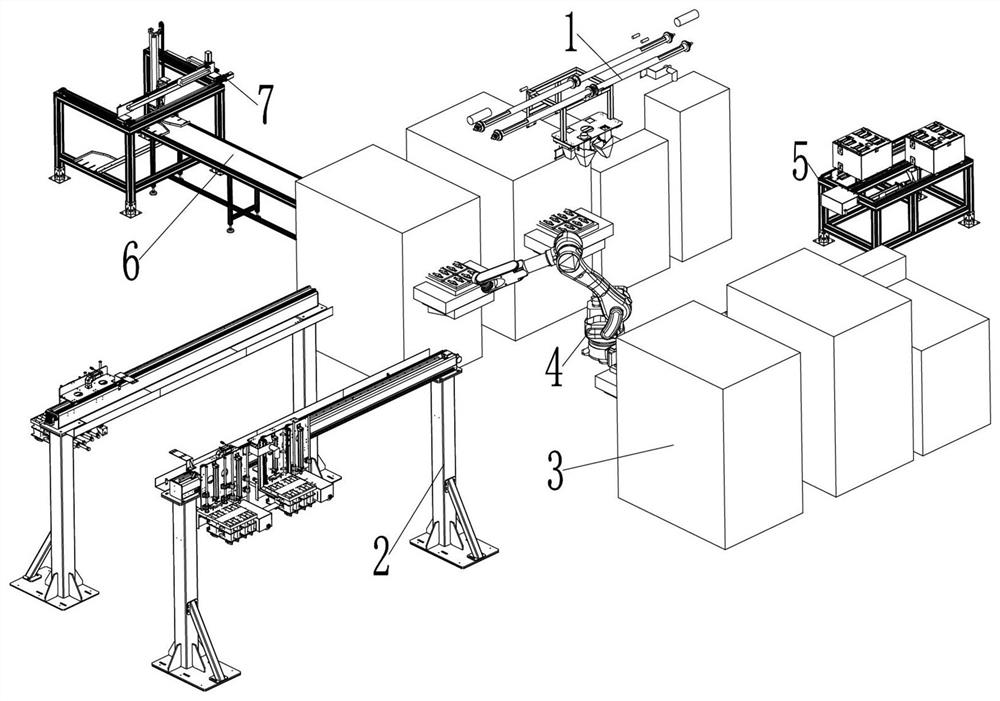

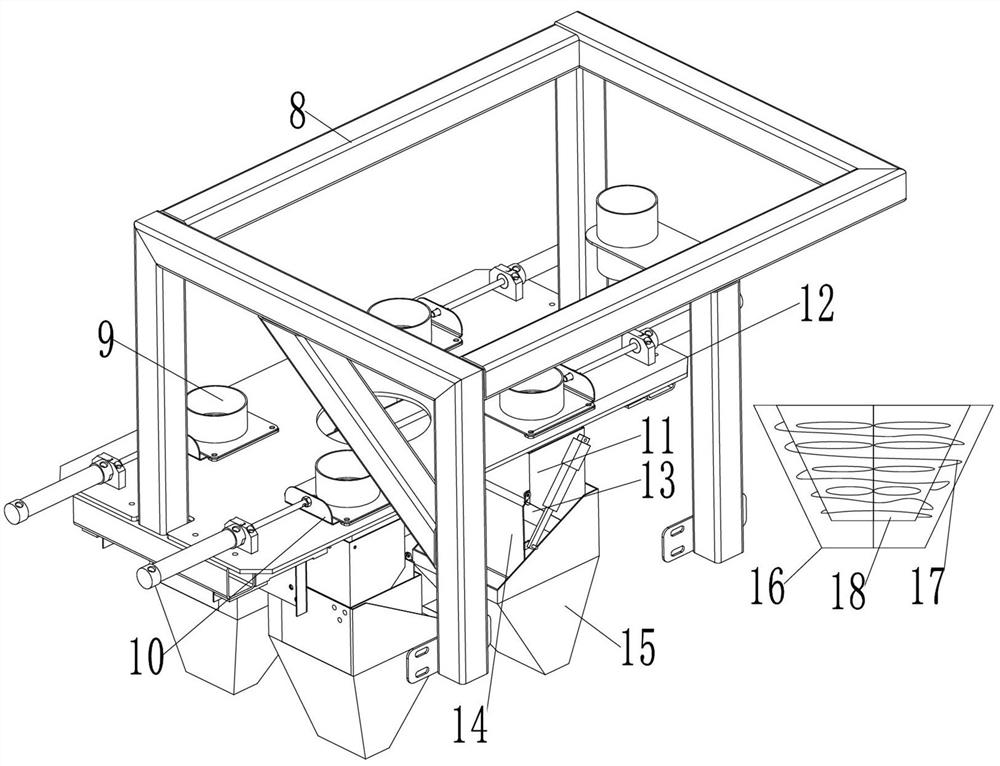

[0054] Such as Figure 1-7 As shown, the disc brake pad production equipment of this embodiment includes a frame assembly, and the frame assembly is provided with

[0055] Weighing mechanism 1, the walking input end is at the raw material output end of the previous line, which is used to weigh the raw materials of the brake pads and then output them;

[0056] The truss feeding mechanism 2, the starting end of the walking is at the output end of the weighing mechanism 1, which is used to weigh each raw material, and quantitatively output each raw material at the walking terminal;

[0057] The steel back feeding mechanism 5, at the end of travel, in the ballast mold 32, is used for the truss feeding mechanism 2 to quantitatively send each raw material to the ballast mold 32 and cover the steel back part 45, and set the glue injection machine to inject glue Liquid, set the vibration motor to vibrate;

[0058] The robot gripper 4 is used for the transfer of the ballast mold 32 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com