An acidolysis corrosion-resistant air pressure discharge tee device

A three-way device, corrosion-resistant technology, used in valve operation/release device, valve device, multi-way valve and other directions, can solve problems such as deformation, easy perforation, etc., achieve high detection accuracy, avoid easy perforation, and high temperature resistance. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

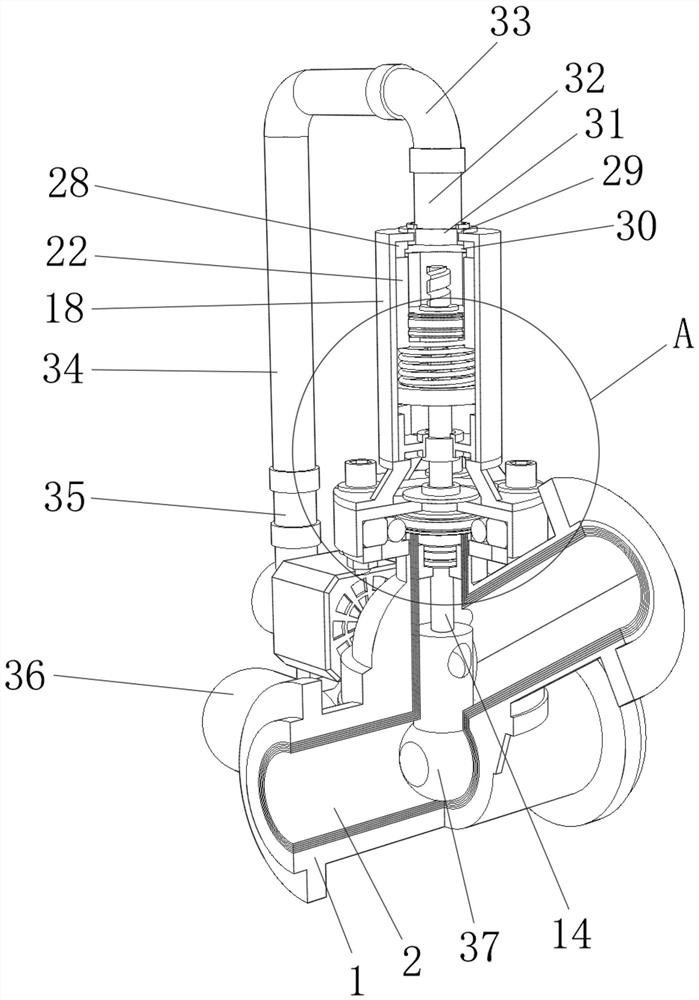

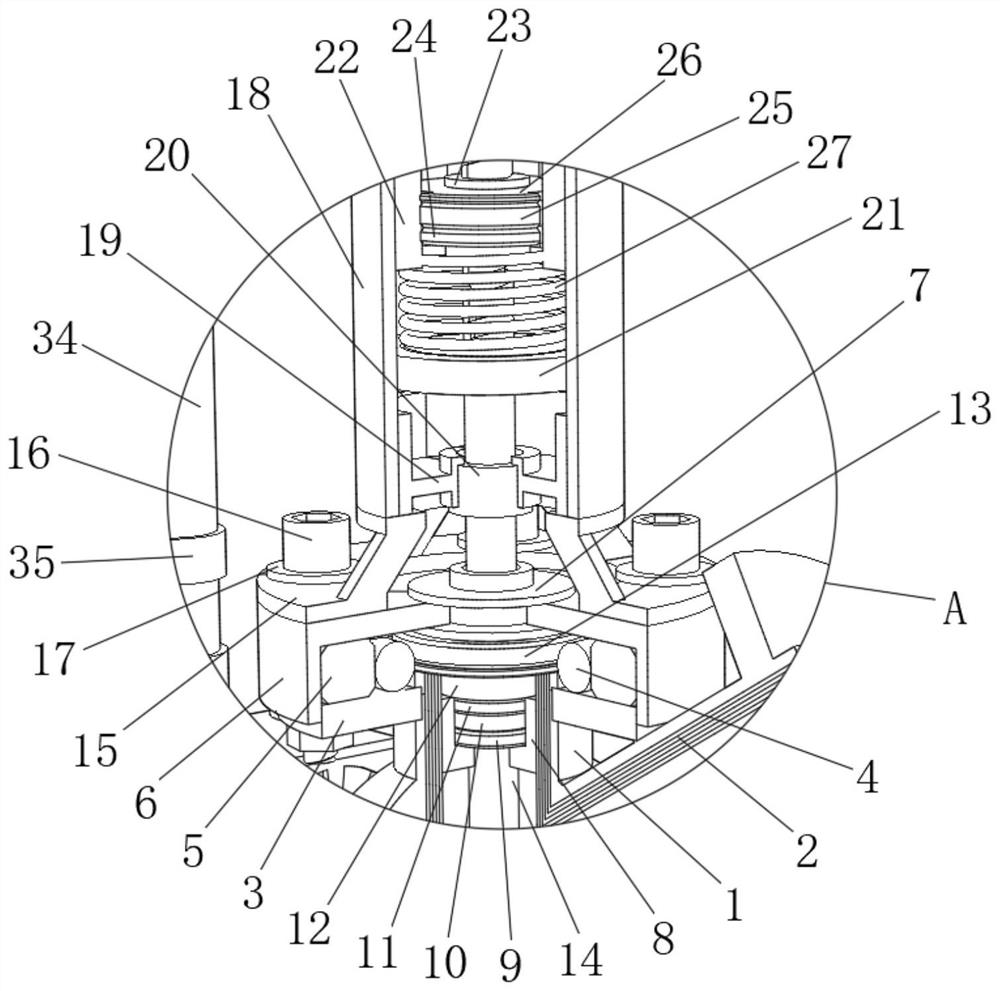

[0030] refer to Figure 1-4 , an acid hydrolysis and corrosion-resistant air pressure discharging tee device, comprising a stainless steel tee pipe 1, the inner wall of the stainless steel tee pipe 1 is sleeved with a multi-layer glass fiber reinforced plastic layer 2, and the stainless steel tee pipe 1 and the glass fiber reinforced plastic layer 2 cooperate The design avoids the easy perforation and deformation of the pipe body channel, making it difficult for the material or medium in the pipe body channel to leak through and corrode the internal structural parts of the device and the working site. Stainless steel lined with FRP can increase its corrosion resistance and high temperature resistance, making Its corrosion resistance and high temperature resistance are greatly improved, and its service life is greatly extended. The top outer wall of the stainless steel tee pipe 1 is fixed with a fixed plate 3 by bolts, and the upper surface of the fixed plate 3 is fixed with a s...

Embodiment 2

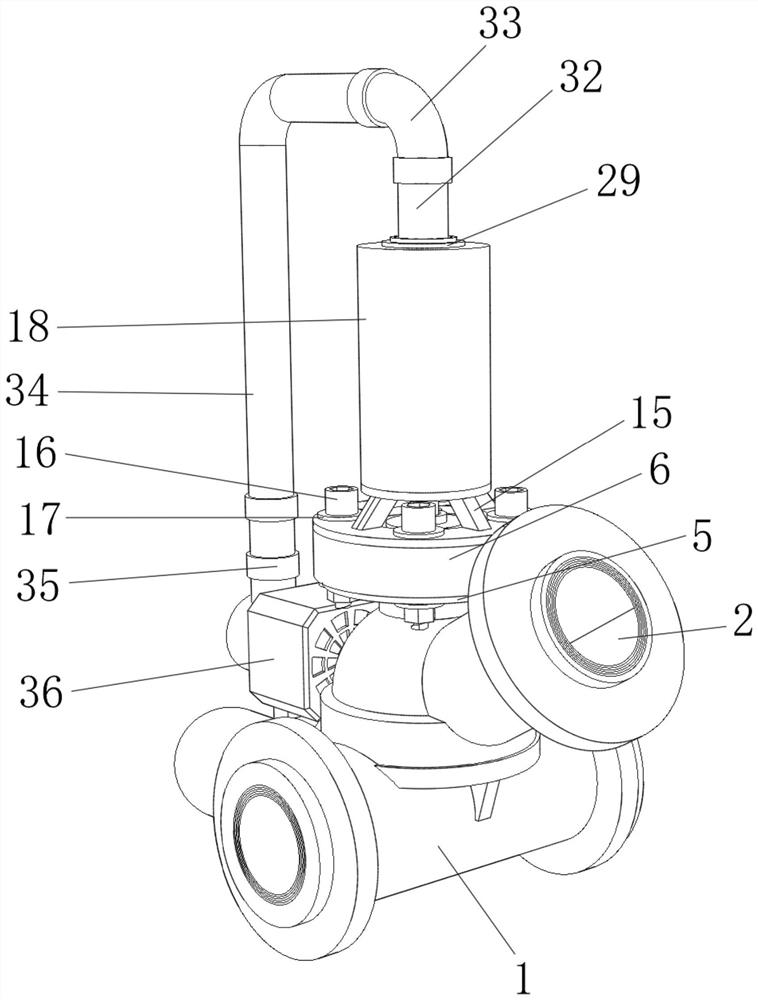

[0034] refer to Figure 5 , an acid hydrolysis and corrosion-resistant air pressure discharging tee device, including a stainless steel tee pipe 1 on both sides of the outer wall is also fixed with a connecting plate 38 by bolts, and a support plate 39 is fixed between the two connecting plates 38 by bolts, through the The cooperating design of the connecting plate 38 and the supporting plate 39 enhances the stability and safety performance of the overall device. A waterproof ring 40 is fixed on one side of the stainless steel tee pipe 1 by bolts. The shape of the waterproof ring 40 can prevent the external water source from directly flowing into the Inside the stainless steel tee pipe 1, the outer circumferential wall of the waterproof ring 40 is fixed with a protective ring 42 by bolts, and the circumferential outer wall of the protective ring 42 is provided with a clamping pad 41, and the outer wall of the stainless steel tee pipe 1 is also provided with an annular clamp, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com