An all metal high temperature resistant screw pump

A high temperature resistant, screw pump technology, used in pumps, pump components, rotary piston pumps, etc., can solve the problems of short working life, leakage, and the inability to produce all-metal screw pumps, and achieve low operating noise and floor space. Less, solve the effect of short working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

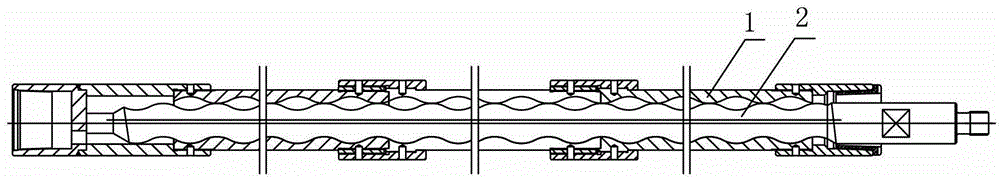

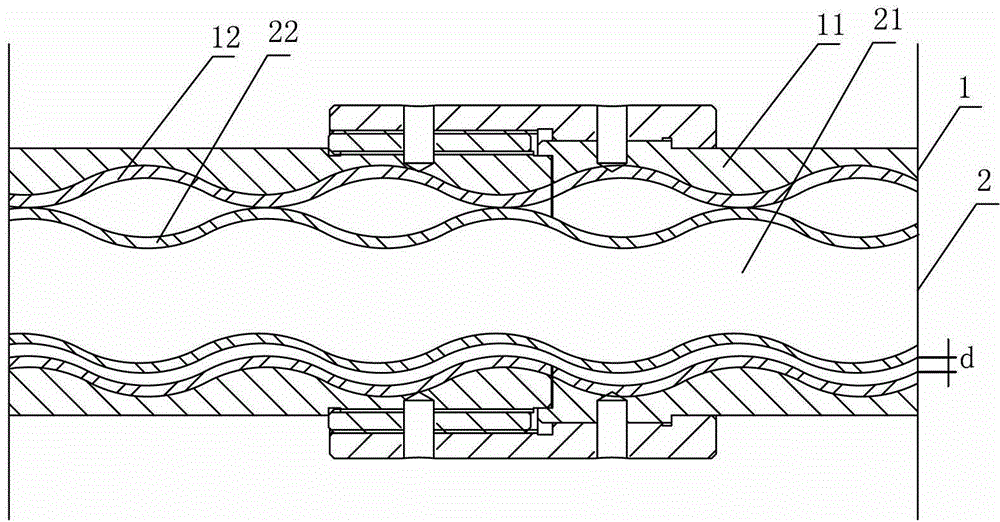

[0013] Embodiment 1: As shown in the figure, an all-metal high-temperature-resistant screw pump includes a metal stator 1 and a metal rotor 2. The inner surface of the metal stator 1 and the outer surface of the metal rotor 2 are in clearance fit, and the inner surface of the metal stator 1 is in contact with the metal rotor 2. The gap distance on the outer surface of the rotor 2 is 0.01 mm. The metal stator 1 includes a stator metal base 11 and a first hard material permeation layer 12 arranged on the inner surface of the stator metal base 11. The metal rotor 2 includes a rotor metal base 21 and is arranged on the rotor metal base 11. The second hard material infiltrated layer 22 on the outer surface of the metal substrate 21, the first hard material infiltrated layer 12 is a tungsten carbide layer with a Hastelloy hardness of HV1100, and the thickness of the first hard material infiltrated layer 12 is 4 microns. The second hard material infiltrated layer 22 is a plasma nitrid...

Embodiment 2

[0014] Embodiment 2: As shown in the figure, an all-metal high-temperature-resistant screw pump includes a metal stator 1 and a metal rotor 2. The inner surface of the metal stator 1 and the outer surface of the metal rotor 2 are in clearance fit, and the inner surface of the metal stator 1 is in contact with the metal rotor 2. The gap distance on the outer surface of the rotor 2 is 0.4 mm. The metal stator 1 includes a stator metal base 11 and a first hard material permeation layer 12 arranged on the inner surface of the stator metal base 11. The metal rotor 2 includes a rotor metal base 21 and is arranged on the rotor metal base 11. The second hard material infiltrated layer 22 on the outer surface of the metal substrate 21, the first hard material infiltrated layer 12 is a tungsten carbide layer with a Hastelloy hardness of HV1200, and the thickness of the first hard material infiltrated layer 12 is 10 microns. The second hard material infiltrated layer 22 is a plasma nitrid...

Embodiment 3

[0015] Embodiment 3: As shown in the figure, an all-metal high-temperature-resistant screw pump includes a metal stator 1 and a metal rotor 2, the inner surface of the metal stator 1 and the outer surface of the metal rotor 2 are in clearance fit, and the inner surface of the metal stator 1 is in contact with the metal rotor 2. The gap distance on the outer surface of the rotor 2 is 0.2 mm. The metal stator 1 includes a stator metal base 11 and a first hard material permeation layer 12 arranged on the inner surface of the stator metal base 11. The metal rotor 2 includes a rotor metal base 21 and is arranged on the rotor metal base 11. The second hard material infiltrated layer 22 on the outer surface of the metal substrate 21, the first hard material infiltrated layer 12 is a tungsten carbide layer with a Hastelloy hardness of HV1150, and the thickness of the first hard material infiltrated layer 12 is 15 microns. The second hard material infiltrated layer 22 is a plasma nitrid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com