A fan structure of a grain dryer and a grain drying machine

A grain dryer and fan technology, applied in the direction of drying solid materials, dryers, drying gas arrangement, etc., can solve the problems of general flexibility and the inability to adjust the fan blowing angle, so as to ensure the service life and avoid heat loss , Improve the effect of heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

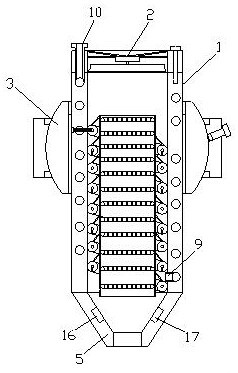

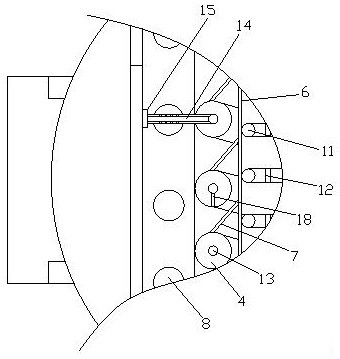

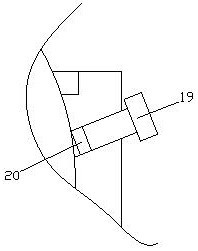

[0026] like Figure 1-3 As shown, a fan structure of a grain dryer includes a heat-insulating air duct 1, a fan 2 and a joint bearing 3. An electric heating iron 4 is arranged inside the heat-insulating air duct 1, and the electric heating iron 4 is arranged in a spiral shape. The electric heating iron 4 is in close contact with the inner pipe wall of the heat-insulating air pipe 1, the end of the heat-insulating air pipe 1 is fixedly connected with the fan 2, and the other end of the heat-insulating air pipe 1 is provided with a duckbill nozzle 5, The electric heating iron 4 is fixedly connected with the heat-insulating air pipe 1, and the heat-insulating air pipe 1 is provided with a heat exchange tube 6, and the heat exchange pipe 6 is inserted into the area where the electric heating iron 4 is wound. 6 and the electric heating iron 4 are provided with a heat conduction rod 7, and the two ends of the heat conduction rod 7 are respectively welded to the heat exchange tube 6 ...

Embodiment 2

[0029] like Figure 1-3 As shown, a fan structure of a grain dryer includes a heat-insulating air duct 1, a fan 2 and a joint bearing 3. An electric heating iron 4 is arranged inside the heat-insulating air duct 1, and the electric heating iron 4 is arranged in a spiral shape. The electric heating iron 4 is in close contact with the inner pipe wall of the heat-insulating air pipe 1, the end of the heat-insulating air pipe 1 is fixedly connected with the fan 2, and the other end of the heat-insulating air pipe 1 is provided with a duckbill nozzle 5, The electric heating iron 4 is fixedly connected with the heat-insulating air pipe 1, and the heat-insulating air pipe 1 is provided with a heat exchange tube 6, and the heat exchange pipe 6 is inserted into the area where the electric heating iron 4 is wound. 6 and the electric heating iron 4 are provided with a heat conduction rod 7, and the two ends of the heat conduction rod 7 are respectively welded to the heat exchange tube 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com