Finite element modeling method for sealing strip of opening and closing piece

A modeling method and finite element technology, applied in the field of auto parts, can solve the problems of low calculation efficiency, poor simulation effect, and increase in the number of finite element meshes of the model, so as to improve efficiency and accuracy and save prototype vehicles. cost, and the effect of improving R&D efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Because the physical test cycle is too long, the cost is too high, and the accuracy of the existing simulation technology is relatively poor, so the industry urgently needs a method that can use finite element simulation to establish models and connections in the early stage of the design of the opening and closing parts, and accurately simulate the opening and closing parts. The sealing strip of the closed frame is a simulation technology for predicting the stress of sheet metal parts in the experimental and actual use states. It can use simulation technology to predict fatigue life and make targeted structural improvements, reduce the number of experiments, shorten the product development cycle, and improve the efficiency of the vehicle development process.

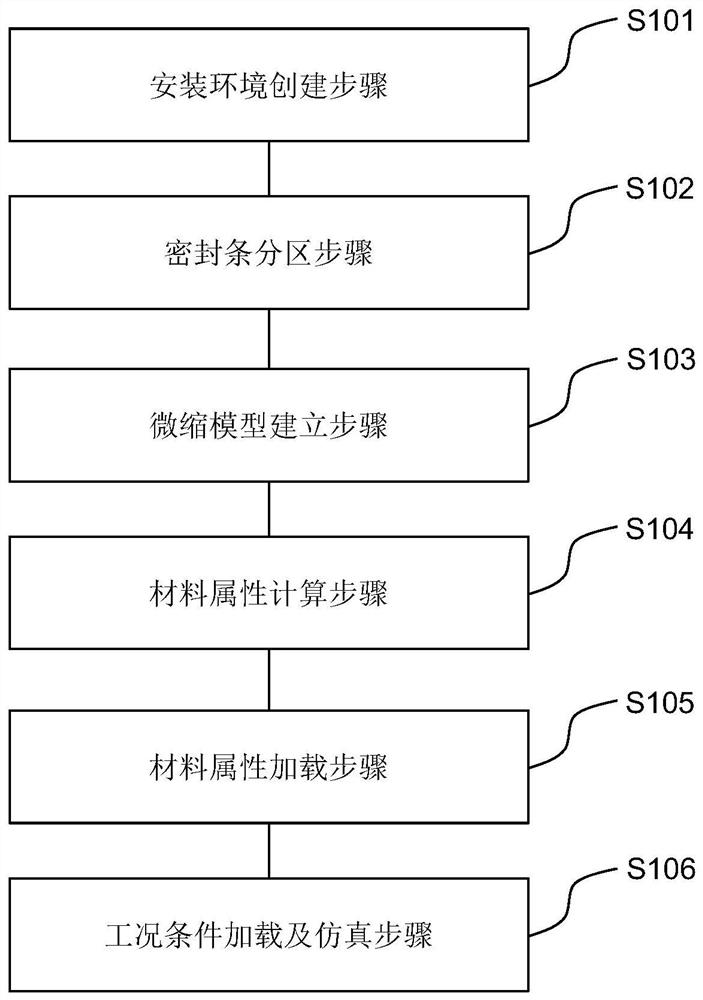

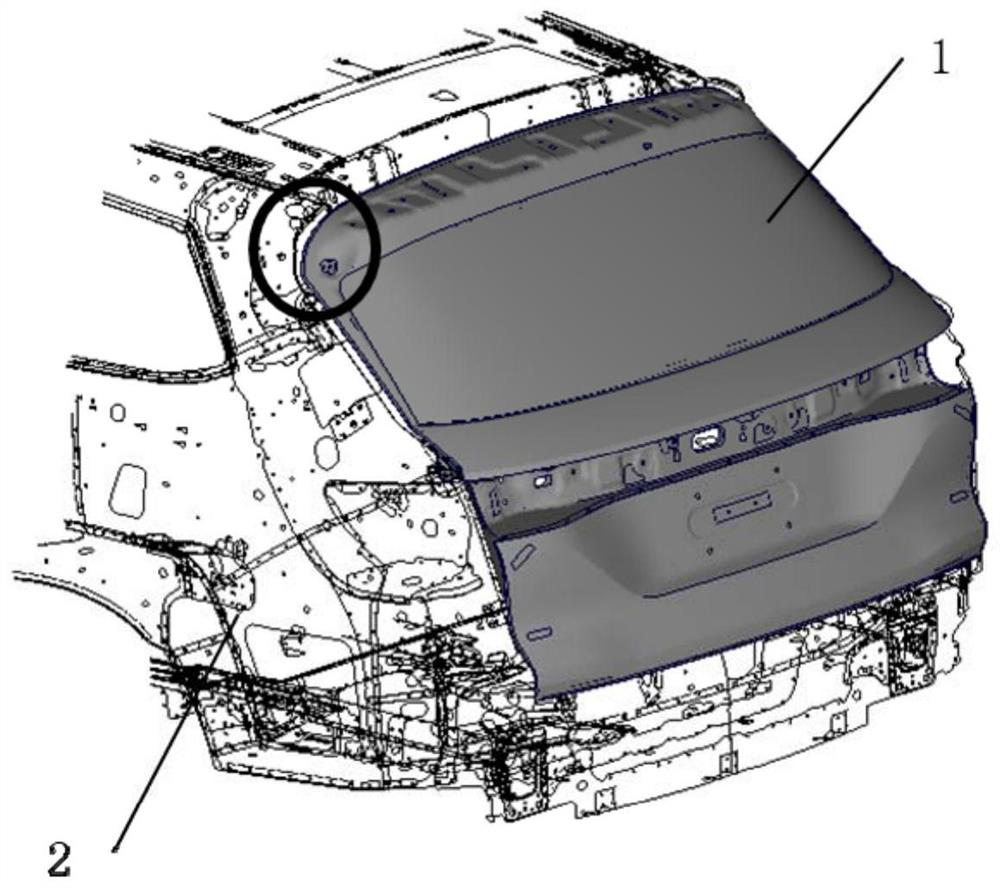

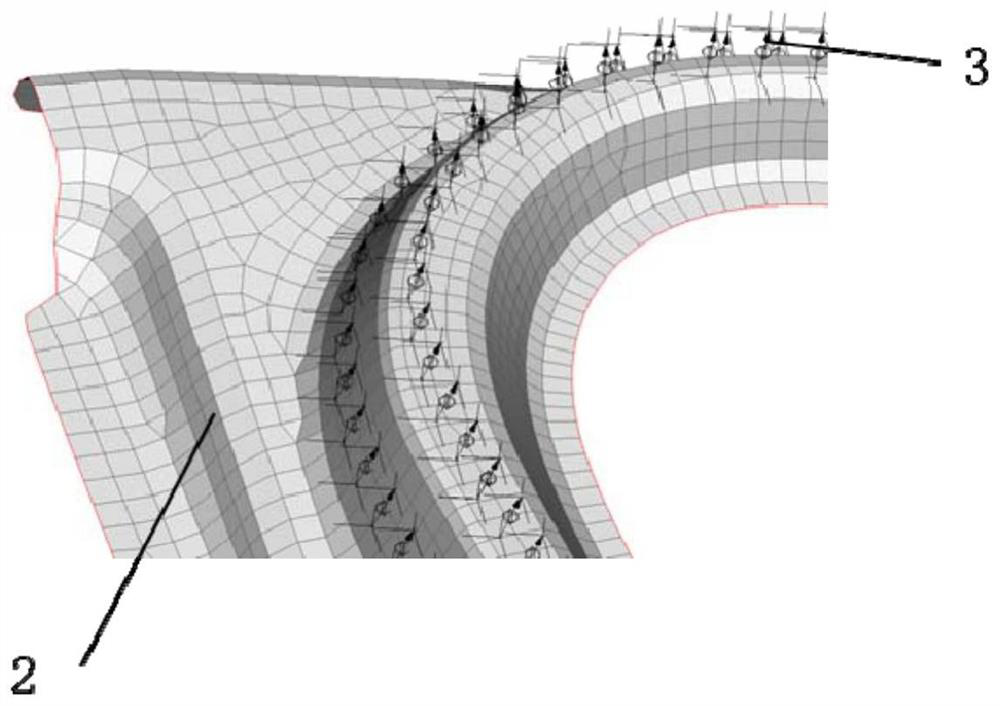

[0059] The invention proposes a finite element modeling method for the sealing strip of the opening and closing parts, figure 1 A flow chart of a finite element modeling method for a sealing strip of an opening a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com