Laser packaging method

A technology of laser encapsulation and laser beam, which is applied in glass forming, glass manufacturing equipment, electrical components, etc., and can solve problems such as missed firing, decreased yield, encapsulation quality, and overburning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

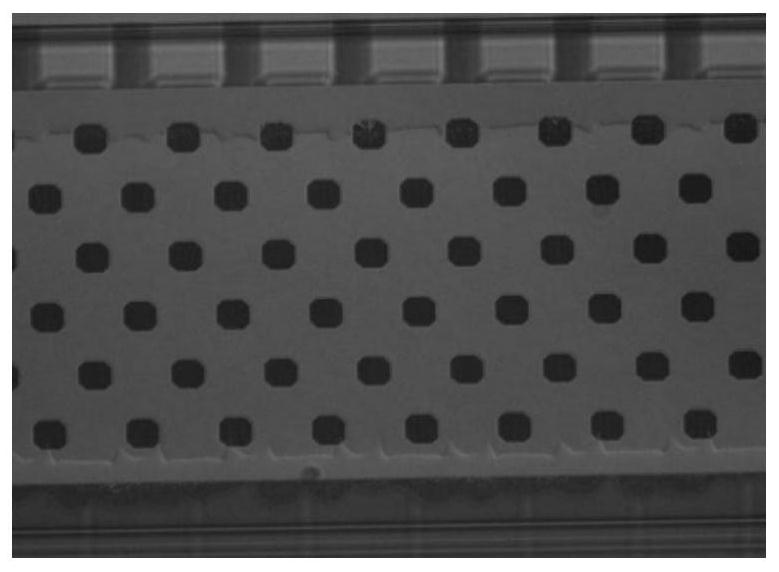

[0035] As mentioned in the background art, when using a single scan rate and laser power to package a group of glass plates, due to the difference in the surface settings of the glass plates, when the traditional laser packaging method is used to irradiate the glass frit in some specific areas, when the laser power is higher If the scanning rate is too large or the scanning rate is too slow, overburning or even cracks may occur, resulting in a decrease in yield, and it is difficult to improve packaging efficiency.

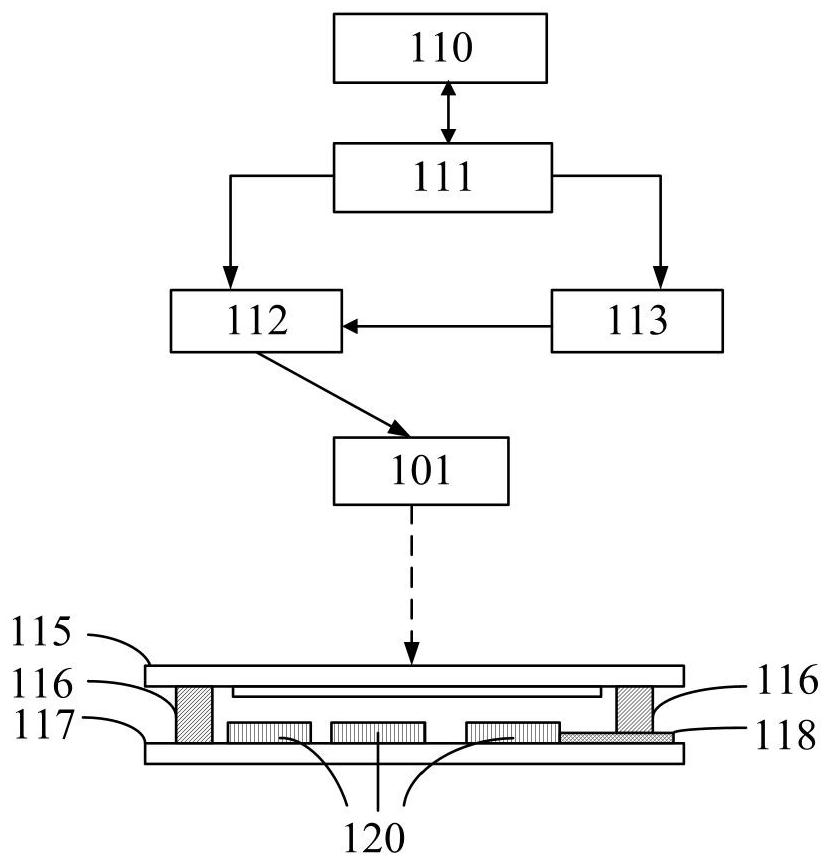

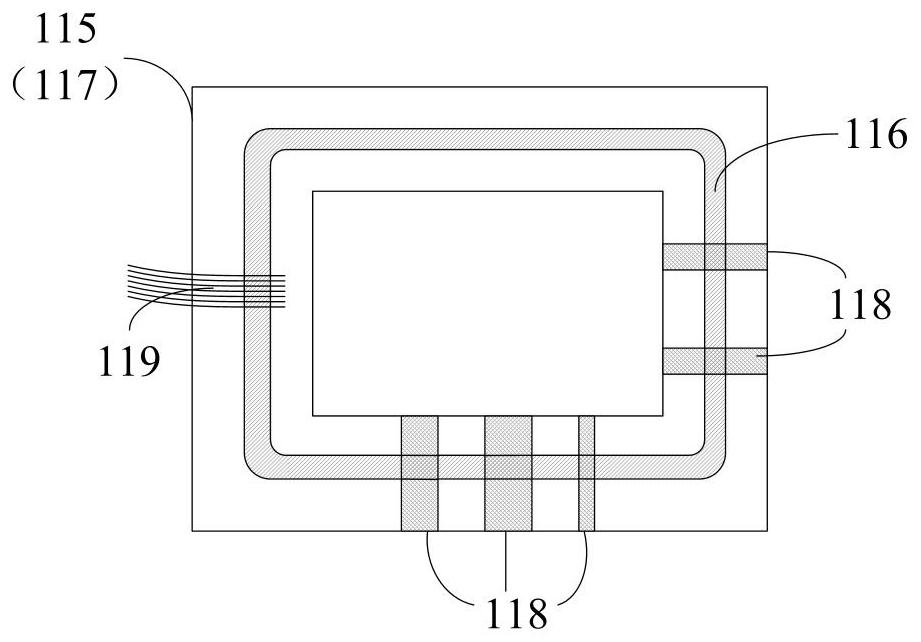

[0036] In order to improve packaging efficiency and product qualification rate while taking into account the packaging quality, the present invention provides a laser packaging method, which uses laser beams to irradiate glass frit coated along a packaging path between a group of glass substrates for packaging. The packaging path includes a crackable area (the "crackable area" here refers to the area where overburning or cracks are likely to occur when the glass fri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com