Battery pack liquid cooling control method and device

A control method and battery pack technology, applied to secondary batteries, circuits, electrical components, etc., can solve the problems of large temperature fluctuations in the cooling process of the battery pack, inability to meet the different needs of water cooling temperature, and affecting the service life of the battery pack. To achieve the effect of prolonging life, prolonging service life and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

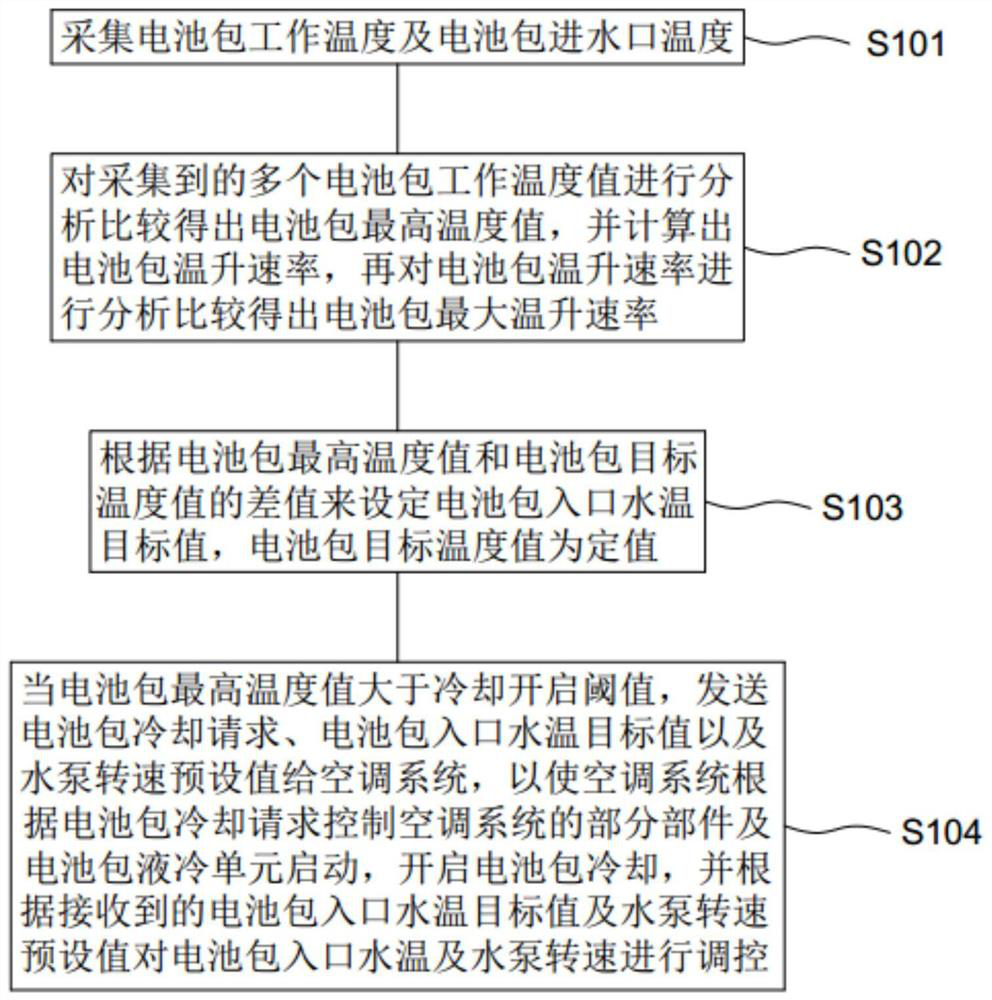

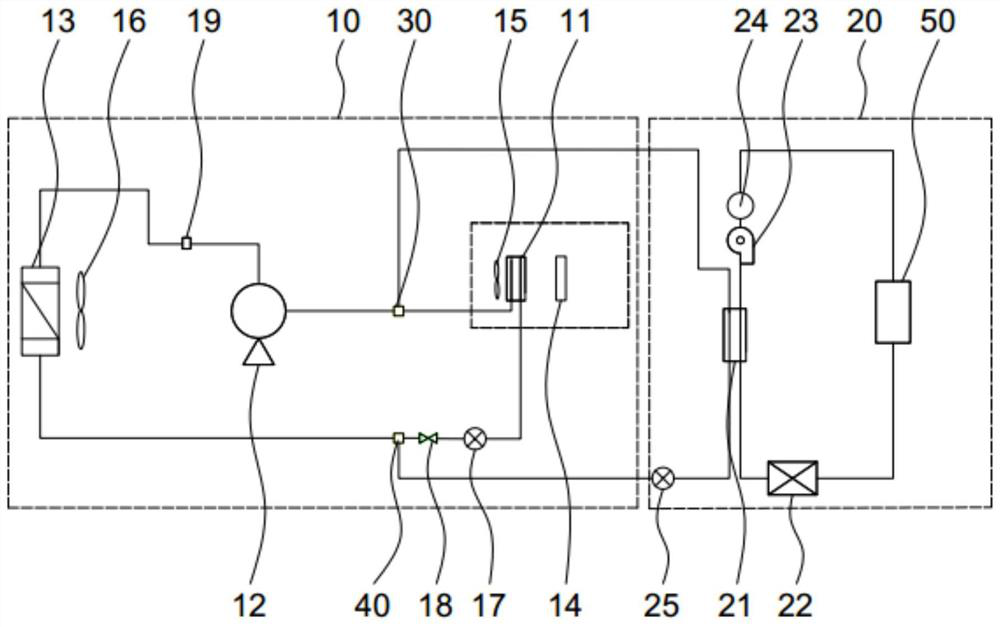

[0044] Please refer to figure 1 and 2 , The first embodiment of the present invention provides a method for controlling liquid cooling of a battery pack, including steps S101-S104.

[0045] S101: Collect the working temperature of the battery pack and the temperature of the water inlet of the battery pack.

[0046] Wherein, during specific implementation, a plurality of temperature sensors can be arranged on the surface of the battery pack 50 to collect the working temperature of the battery pack, and the temperature sensor of the water inlet of the battery pack 50 can be used to collect the temperature of the coolant at the water inlet of the battery pack.

[0047] S102: Analyze and compare the collected operating temperature values of multiple battery packs to obtain the maximum temperature value of the battery pack, and calculate the temperature rise rate of the battery pack, and then analyze and compare the temperature rise rate of the battery pack to obtain the maximum...

Embodiment 2

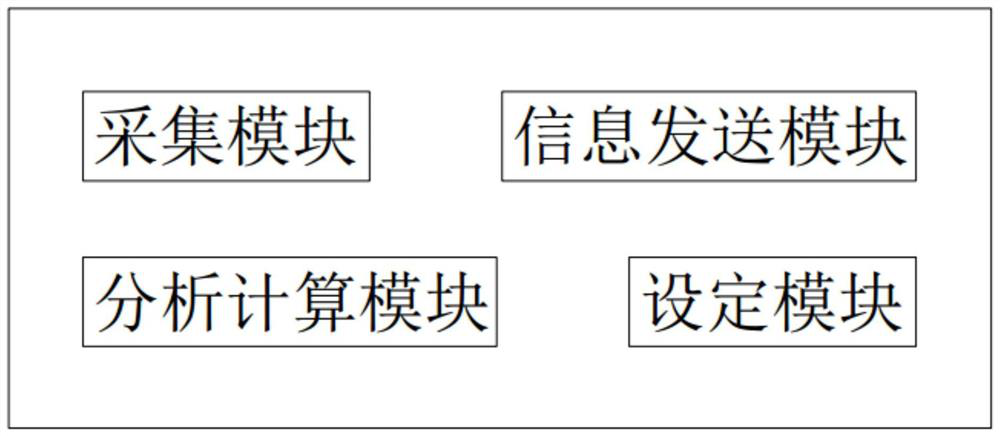

[0061] Please refer to image 3 , the second embodiment of the present invention provides a battery pack liquid cooling control device, including:

[0062] Acquisition module: collect the working temperature of the battery pack and the temperature of the water inlet of the battery pack.

[0063] Wherein, during specific implementation, a plurality of temperature sensors can be arranged on the surface of the battery pack 50 to collect the working temperature of the battery pack, and the temperature sensor of the water inlet of the battery pack 50 can be used to collect the temperature of the coolant at the water inlet of the battery pack.

[0064] Analysis and calculation module: analyze and compare the collected operating temperature values of multiple battery packs to obtain the maximum temperature value of the battery pack, and calculate the temperature rise rate of the battery pack, and then analyze and compare the temperature rise rate of the battery pack to obtain the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com