A Vibration Suppression Method of Pine Cone Picking Device Based on QL-SI Algorithm

A technology of vibration suppression and algorithm, which is applied to picking machines, manufacturing tools, program-controlled manipulators, etc., can solve problems such as inaccurate positioning of equipment, inability to hit pinecone branches accurately, and affecting the efficiency of pine cone picking operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

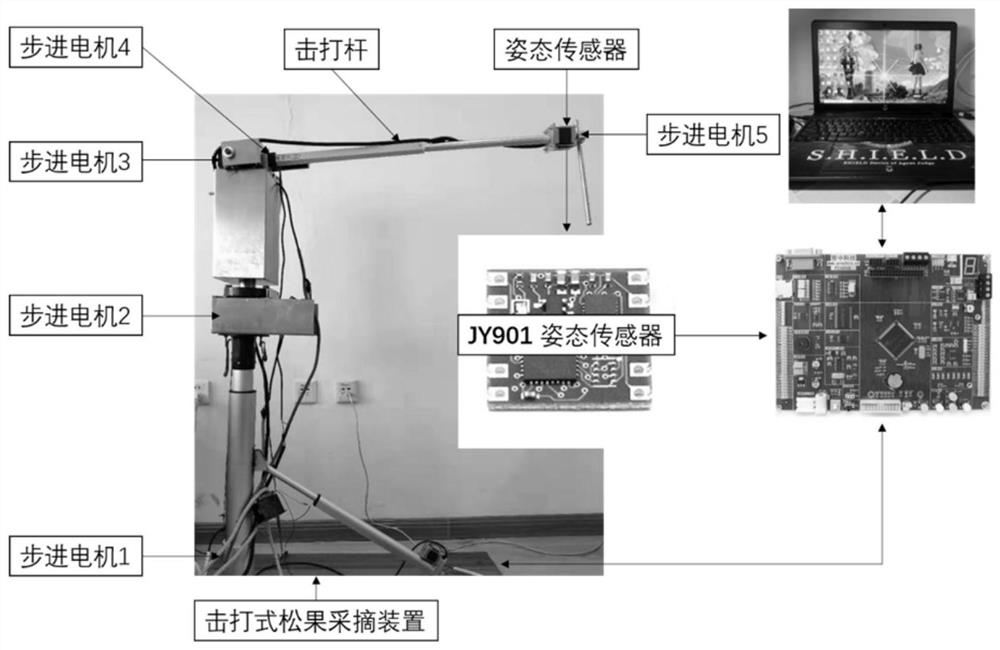

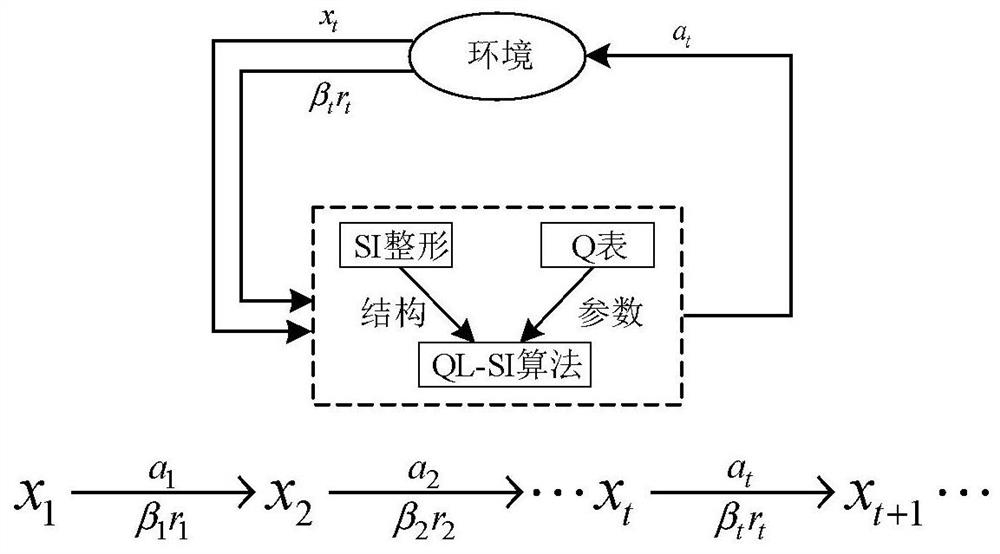

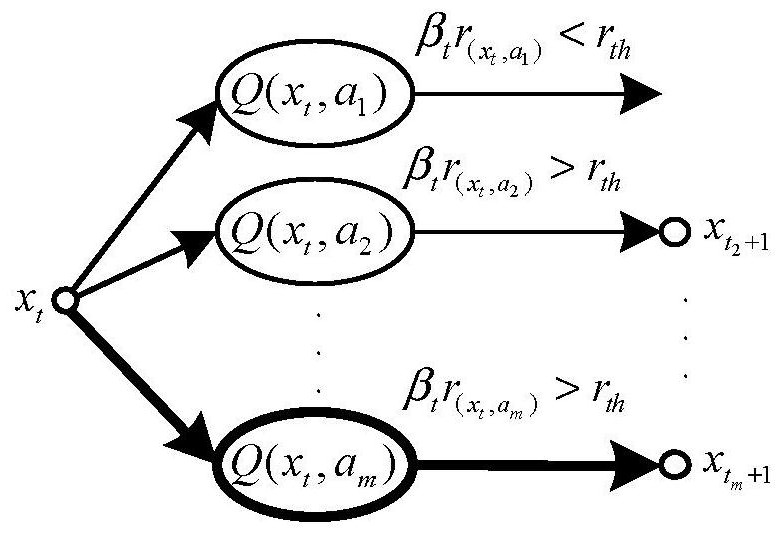

[0048] combined with Figures 1 to 11 , the realization of a kind of QL-SI algorithm-based pine cone picking device vibration suppression method according to the present invention is set forth as follows:

[0049] 1 System structure of hitting type picking device

[0050] figure 1 The striking pine cone picking arm shown is composed of a multi-joint robotic arm and a controller, wherein the multi-joint robotic arm is composed of a connecting rod, a planetary reducer, a coupling, a stepping motor and a base, and the controller It consists of two parts, the STM32 controller and the stepper driver. The models and functions of the components are shown in Table 1. In order to realize the real-time control of hitting, the sampling period is set to 1ms.

[0051] Table 1 Component list

[0052]

[0053] Stepper motor 1 completes the vertical movement through the hydraulic rod, stepper motor 2 completes the 360-degree horizontal rotation through the planetary reducer driving the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com