Method for determining and verifying screw channel for bone surgery based on three-dimensional modeling

A three-dimensional modeling and verification method technology, applied in computer-aided surgery, computer-aided planning/modeling, medical science, etc., can solve the problems of difficult screw paths, poor intraoperative guidance, and high error rates, and achieve application Low cost, improved nail placement accuracy, and easy popularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

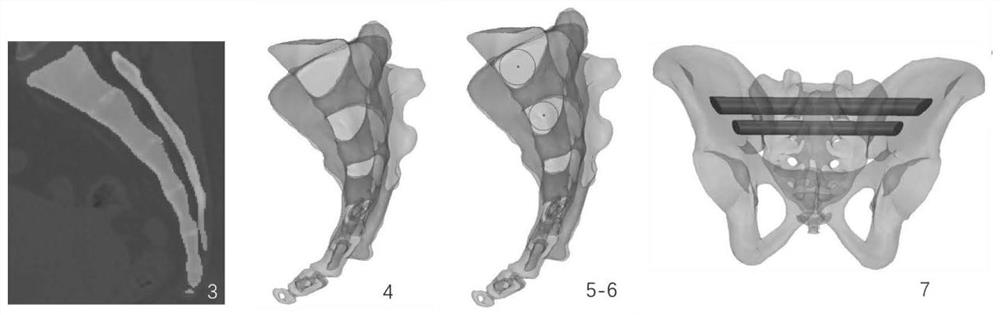

[0034] like figure 1 As shown, a method for determining and verifying the sacral transverse screw channel based on three-dimensional modeling includes the following steps:

[0035] S1. Obtain 256 rows of dual-source CT scan data of the sacrum. The scan parameters are: voltage 120kV, current 150mA, slice thickness 0.625mm, scan without interval, scan matrix 512X512 pixels, and save it in Dicom format;

[0036] S2, importing the original Dicom data into the three-dimensional modeling software Mimics 22.0 (Materialise company, Belgium);

[0037] S3. Create a new bone mask in "new mask". In the middle layer of the coronal plane, use "split mask" to separate the sacrum mask from the upper and lower adjacent vertebral body masks, and "region growing" to separate the two-dimensional mask of the sacrum independently Come out and fill the bone completely in the mask;

[0038] S4. Reconstruct the three-dimensional model of the sacrum based on the above-mentioned two-dimensional mask "...

Embodiment 2

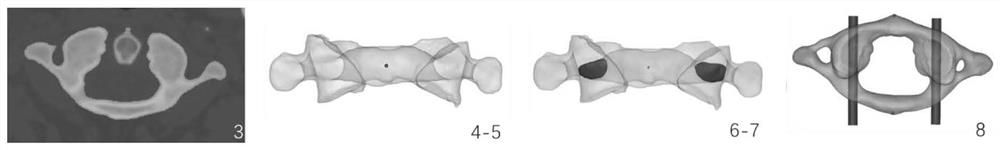

[0043] like figure 2 As shown, a method for determining and verifying the pedicle screw channel of the atlas without inclination angle based on three-dimensional modeling includes the following steps:

[0044] S1. Obtain 256 rows of dual-source CT scan data of the sacrum. The scan parameters are: voltage 120kV, current 150mA, slice thickness 0.625mm, scan without interval, scan matrix 512X512 pixels, and save it in Dicom format;

[0045] S2, importing the original Dicom data into the three-dimensional modeling software Mimics 22.0 (Materialise company, Belgium);

[0046] S3. Create a new bone mask in "newmask", and use "split mask" to separate the atlas mask from the upper and lower adjacent vertebral body masks in the middle layer of the coronal plane, and use "region growing" to separate the two-dimensional mask of the atlas Segment it and fill the bone completely in the mask;

[0047] S4. Reconstruct the three-dimensional model of the atlas based on the above-mentioned t...

Embodiment 3

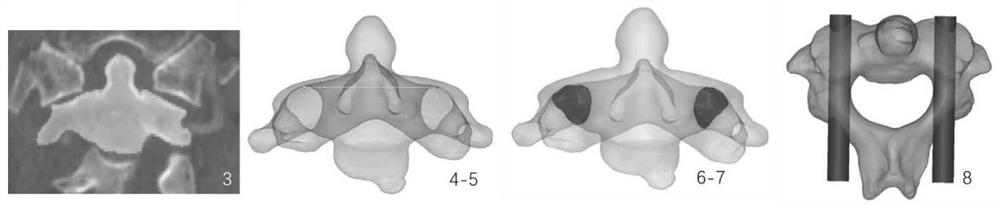

[0053] like image 3 As shown, a method for determining and verifying the pedicle screw channel of the axis without inclination angle based on three-dimensional modeling includes the following steps:

[0054] S1. Obtain 256 rows of dual-source CT scanning data of the axis vertebrae. The scanning parameters are: voltage 120kV, current 150mA, slice thickness 0.625mm, no interval scanning, scanning matrix 512X512 pixels, and save in Dicom format;

[0055] S2, importing the original Dicom data into the three-dimensional modeling software Mimics 22.0 (Materialise company, Belgium);

[0056]S3. Create a new bone mask in "new mask". In the middle layer of the coronal plane, use "split mask" to separate the mask of the axis from the upper and lower adjacent vertebrae. "region growing" separate the two-dimensional mask of the axis Segment it independently, and fill the bone completely in the mask;

[0057] S4. Reconstruct the three-dimensional model of the axis based on the above-men...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com