A kind of reinforced dental resin filler based on hollow mesoporous silicon microspheres and its preparation method and application

A hollow mesoporous, silicon microsphere technology, applied in the field of biomedical engineering, can solve problems such as patient allergies, and achieve the effects of prolonging the release time, increasing the load, and improving the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

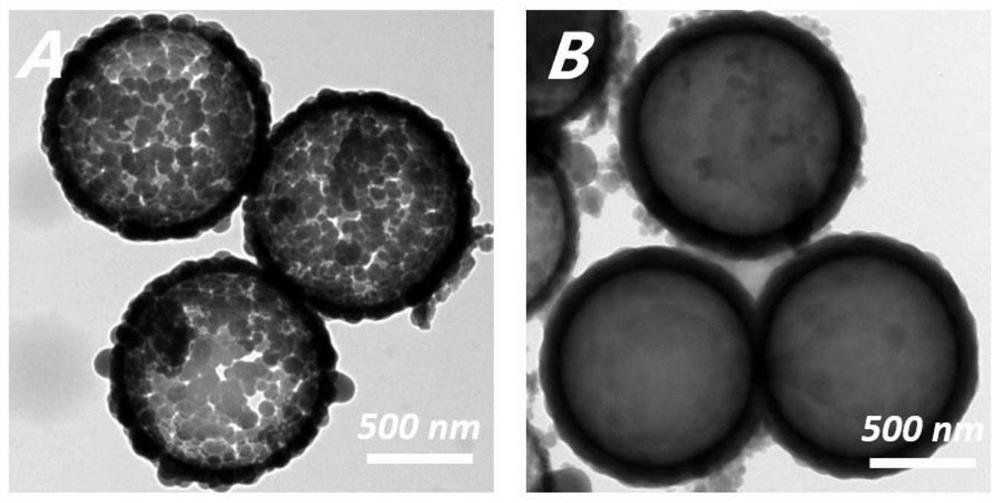

[0032] A method for preparing a reinforced dental resin filler based on hollow mesoporous silicon microspheres is provided, and the specific steps are as follows:

[0033] (1) At room temperature, add 250 mg of surface amination-modified positively charged polystyrene microspheres to a beaker filled with 30 mL of ethanol to disperse, and ultrasonicate for 5 minutes at a power of 400 W to obtain liquid I;

[0034] (2) Place liquid I on a magnetic stirrer at a stirring speed of 200 rpm and stir for 15 minutes, heat to 50°C, then add 2.50 mL of concentrated ammonia water to obtain liquid II;

[0035] (3) Weigh 0.65 g of tetraethyl silicate and add it to liquid II, place it on a magnetic stirrer and continue stirring for 1 hour to obtain liquid III of the suspension;

[0036] (4) Centrifuge liquid III at 4000 rpm, wash repeatedly with deionized water and absolute ethanol until the pH value of the washing liquid is between 7 and 7.5, filter the suspension, dry it in vacuum, and cal...

Embodiment 2

[0041] A method for preparing a reinforced dental resin filler based on hollow mesoporous silicon microspheres is provided, and the specific steps are as follows:

[0042] (1) At room temperature, add 500 mg of surface amination-modified positively charged polystyrene microspheres into a beaker filled with 60 mL of ethanol to disperse, and ultrasonicate for 5 minutes at a power of 400 W to obtain liquid I;

[0043] (2) Place liquid I on a magnetic stirrer at a stirring speed of 200 rpm and stir for 15 minutes, heat to 50°C, and then add 4.50 mL of concentrated ammonia water to obtain liquid II;

[0044] (3) Weigh 1.50 g of tetraethyl silicate and add it into liquid II, place it on a magnetic stirrer and continue stirring for 1 hour to obtain liquid III of the suspension;

[0045] (4) Centrifuge liquid III at 4000 rpm, wash repeatedly with deionized water and absolute ethanol until the pH value of the washing liquid is between 7–7.5, filter the suspension, dry it in vacuum, and...

Embodiment 3

[0055] A method for preparing a reinforced dental resin filler based on hollow mesoporous silicon microspheres is provided, and the specific steps are as follows:

[0056] (1) At room temperature, add 1000 mg of surface amination-modified positively charged polystyrene microspheres into a beaker filled with 120 mL of ethanol to disperse, and ultrasonicate for 5 minutes at a power of 400 W to obtain liquid I;

[0057] (2) Place liquid I on a magnetic stirrer at a stirring speed of 200 rpm and stir for 15 minutes, heat to 55°C, and then add 9.8 mL of concentrated ammonia water to obtain liquid II;

[0058] (3) Weigh 3.50 g of tetraethyl silicate and add it into liquid II, place it on a magnetic stirrer and continue stirring for 1 hour to obtain liquid III of the suspension;

[0059] (4) Centrifuge liquid III at 4000 rpm, wash repeatedly with deionized water and absolute ethanol until the pH value of the washing liquid is between 7 and 7.5, filter the suspension, dry it in vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com