Double-sleeve pipe negative-pressure flushing integrated machine

An all-in-one, double cannula technology, applied in enema/irrigator, promoting communication between physicians or patients, instruments, etc., can solve the influence of disease judgment, accumulate in the abdominal cavity and not be detected in time, and there are other negative effects. Pressure, corrosion of blood vessels and other problems, to avoid the deterioration of the disease, reduce medical disputes, reduce the effect of occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

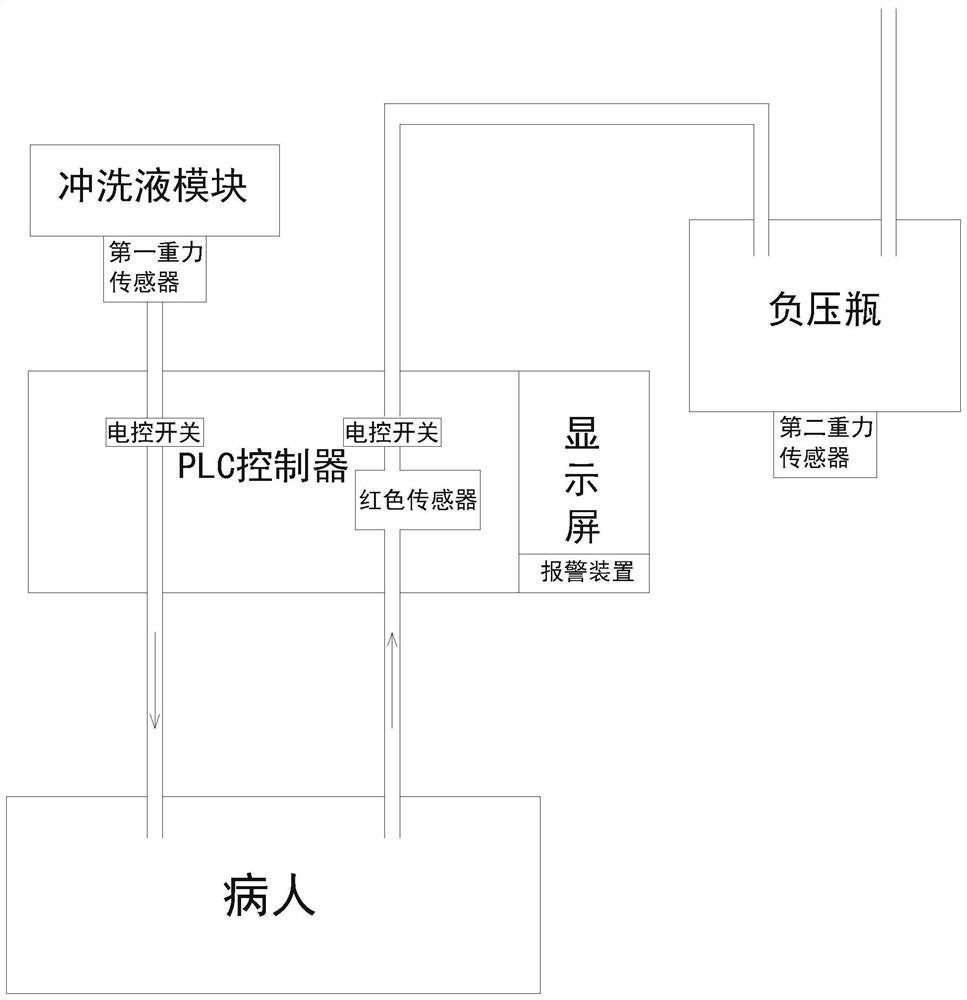

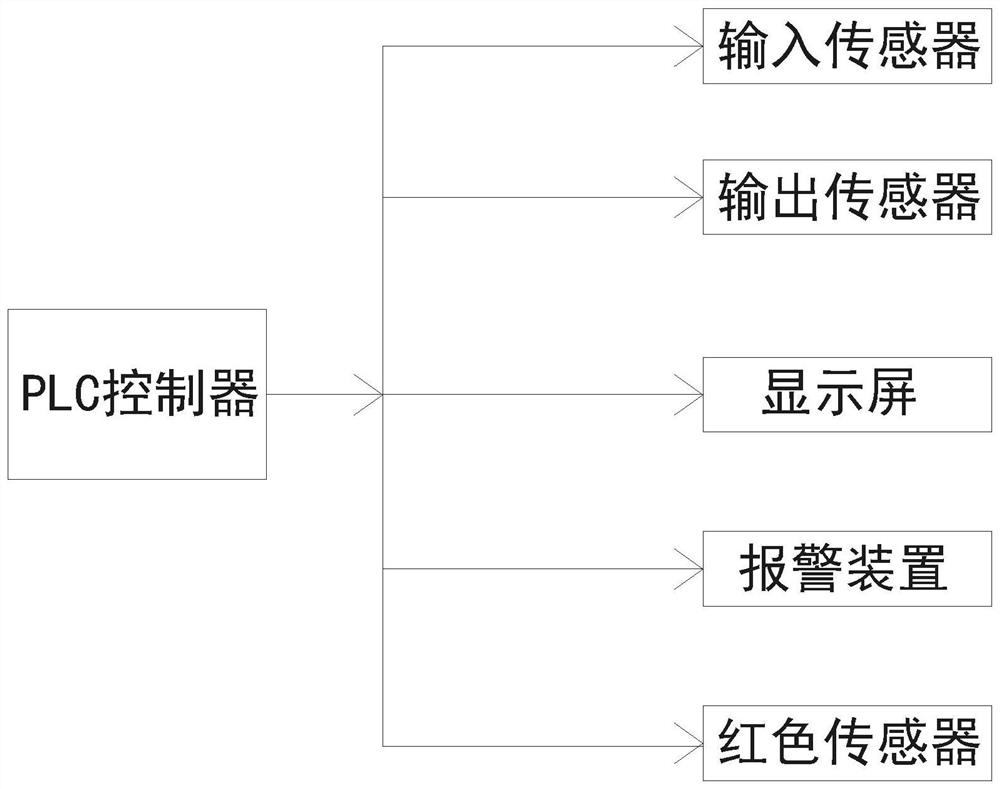

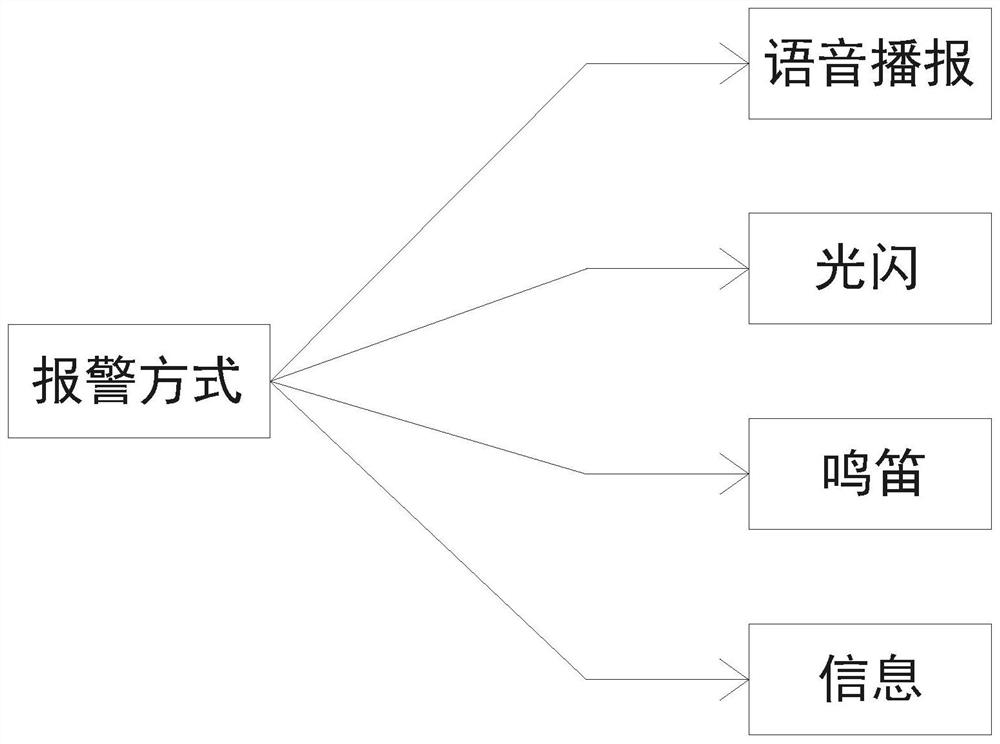

[0026] see Figure 1-3 , a dual-cannula negative pressure flushing machine, including a flushing liquid module, a PLC controller, and a negative pressure bottle; the negative pressure ends of the flushing liquid module and the negative pressure bottle are connected to the patient's intraperitoneal drainage through tubes, and the tubes can be One-time disassembly is convenient for different patients to replace. Both the flushing liquid module and the negative pressure bottle are connected to the PLC controller, and the opening and closing are controlled by the PLC controller; a first gravity sensor is installed at the lower end of the flushing liquid module to monitor the flushing liquid. The remaining liquid volume of the module; a second gravity sensor is installed at the lower end of the negative pressure bottle to monitor the liquid volume in the negative pressure bottle; both the first gravity sensor and the second gravity sensor are connected to the PLC controller and will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com