Button cell surface defect detection system

A button battery and defect detection technology, applied in sorting and other directions, can solve the problems of inability to achieve large-scale inspection, relying on manual inspection, and unable to meet the detection of various defects on the surface of button batteries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

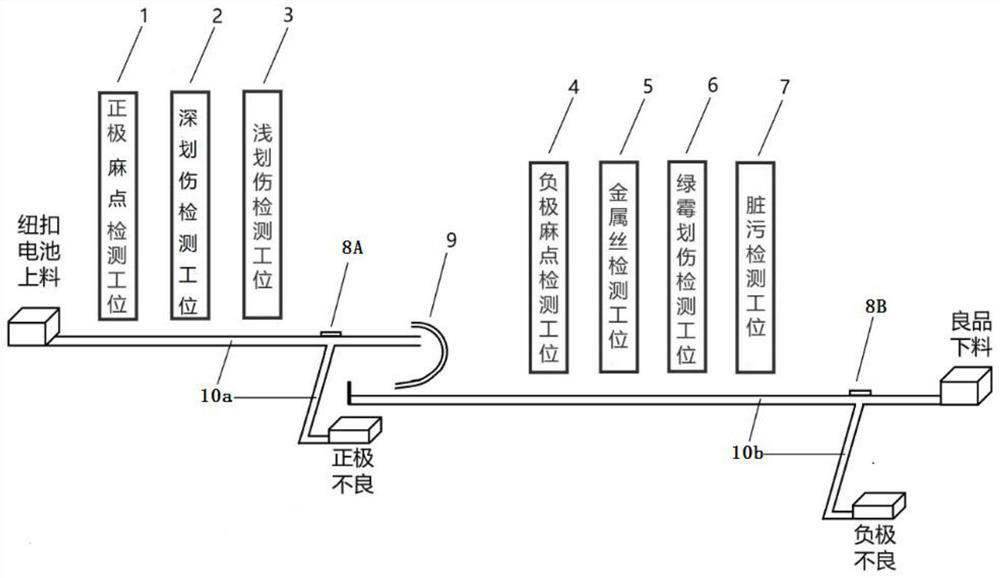

[0012] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

[0013] Such as figure 1 As shown, the preferred embodiment of the present invention is a button battery surface defect detection system, including positive pitting detection station (1), deep scratch detection station (2), shallow scratch detection station (3), negative pole pitting Point detection station (4), metal wire detection station (5), green mildew scratch detection station (6), dirt detection station (7), kicking device, turning device (9), positive detection conveyor belt (10a), negative electrode detection conveyor belt (10b).

[0014] The above-mentioned positive pitting detection station (1), deep scratch detection station (2) and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com