Printed circuit board (PCB) automatic detection production line and application method thereof

An automatic detection and PCB board technology, which is applied in the field of PCB board production line, can solve the problems of affecting enterprise benefits, high cost, poor accuracy, etc., and achieve the effect of improving the utilization rate of board materials, improving quality and efficiency, and preventing manual operation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make it easier for those skilled in the art to understand the present invention, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings.

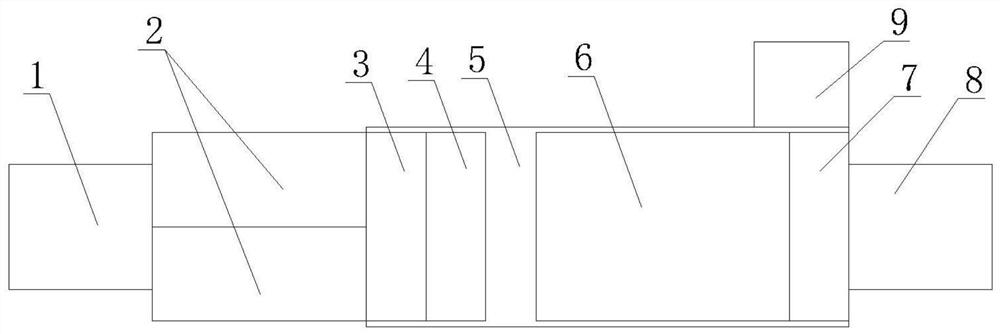

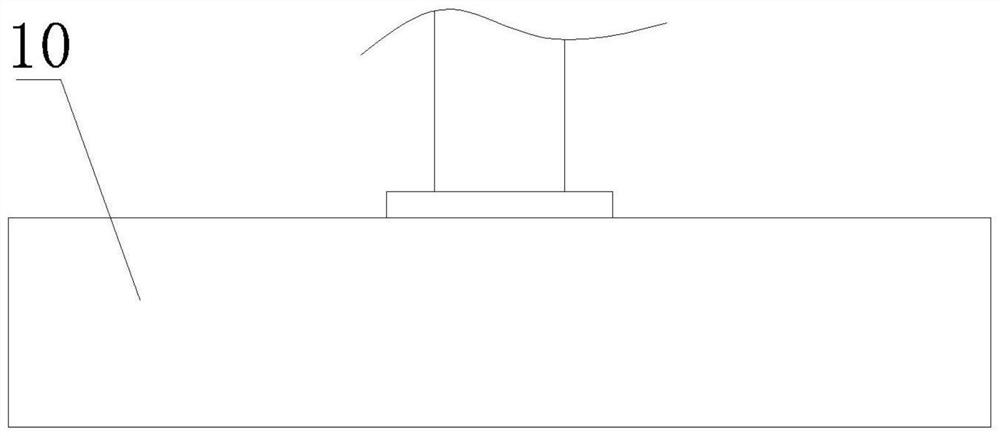

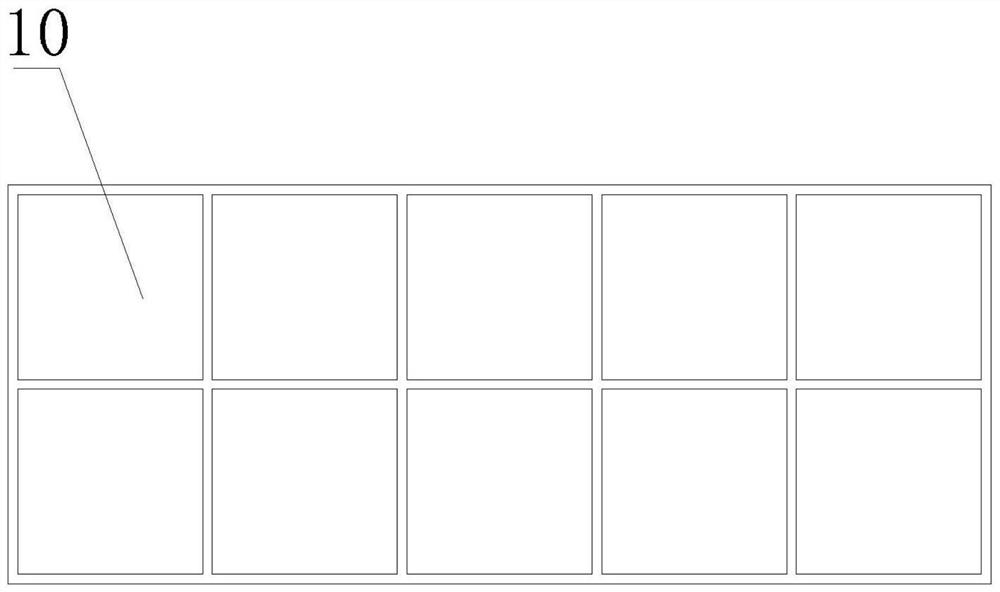

[0035] like Figure 1~3 As shown, the present invention provides a PCB board automatic detection production line, the production line is a linear production line, the total length is 3m, the width is greater than 1m, and the height is 3m. It includes a board-splitting module, a detection module, a delivery module, a first manipulator 3, a code scanner 4, a second manipulator 7, and an NG board storage area 9, and the board-splitting module includes several automatic board-splitting machines 2 arranged side by side. The feeding platform 1 at the feeding end of the automatic plate splitter 2. The quantity of the automatic board splitter 2 depends on the production tasks of the factory, and can be one, two, or even more. Preferably, taking cost and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com