Cleaning tool for cylinder seat of aircraft brake device

The technology of a brake device and a cylinder seat is applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., which can solve the problems of poor cleaning effect and low cleaning efficiency, and achieve improved cleaning efficiency and comprehensive cleaning range , The effect of eliminating pollution sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

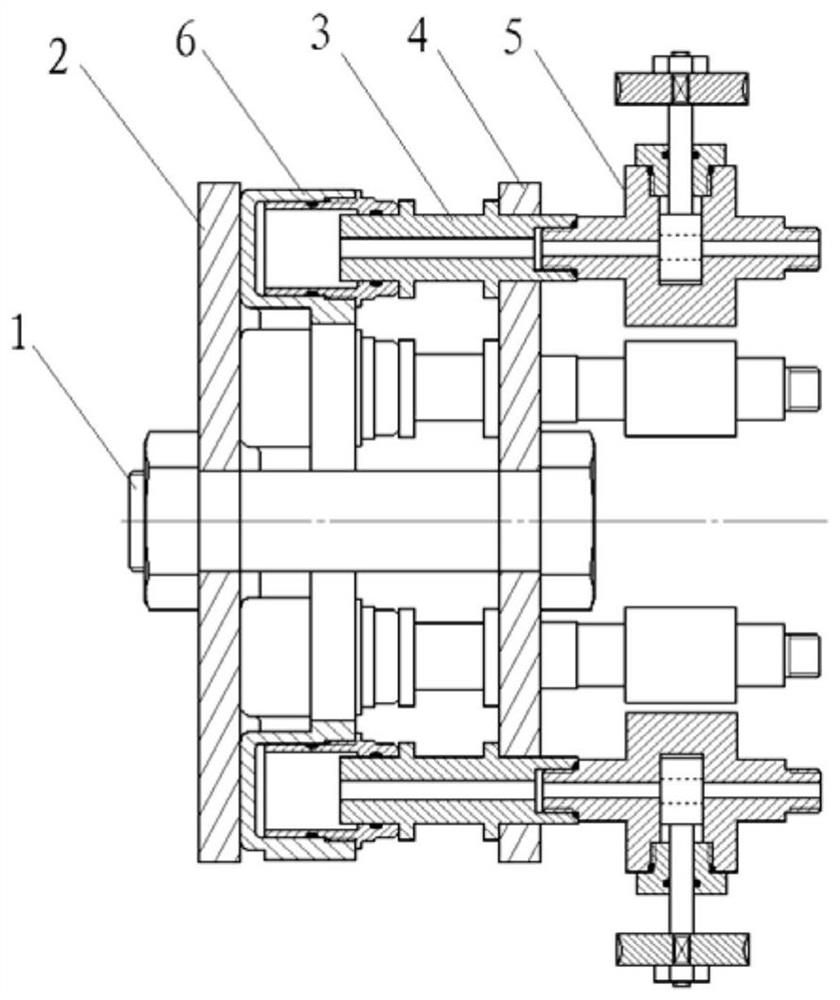

[0057] See attached figure 1 , Figure 6 , with Figure 4 and Figure 5 . The cylinder block cleaning tool for the aircraft braking device provided in this embodiment may include: an adapter 3 , a pressure plate 2 , a fixing plate 4 , a bolt 1 , and a switch 5 . The number of pieces of the adapter 3 and the switch 5 is the same, and is equal to the number of the cleaned aircraft brake device cylinder block piston holes. There is no protrusion on the end face of the cylinder block 6 of the aircraft braking device of this embodiment, and the oil inlet and the air release nozzle are on the side of the cylinder block 6 periphery, and the axes of the oil inlet and the air release nozzle are parallel to the two end faces of the cylinder block 6, and the cylinder block There are 6 evenly distributed piston holes on one side of 6, therefore, there are 6 adapters 3 and 6 switches 5. In this embodiment, the piston hole of the cylinder block is equipped with a piston bushing with a ...

Embodiment 2

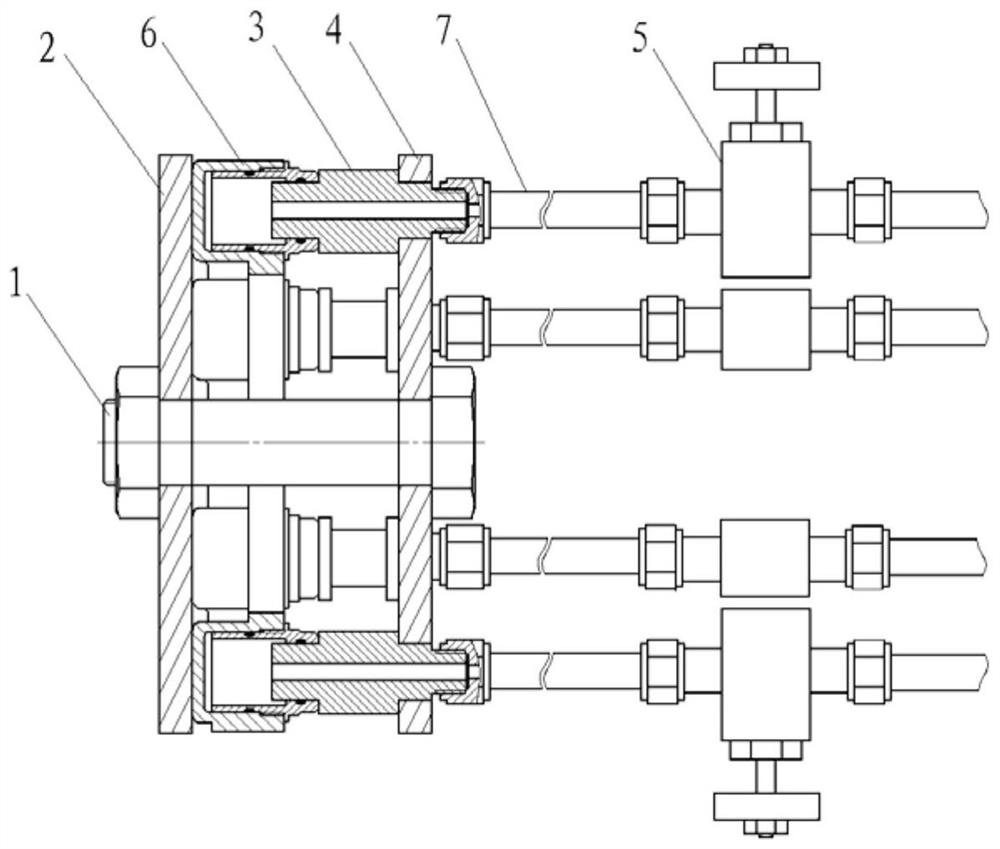

[0069] This embodiment differs from Embodiment 1 in that: 1. The shoulders arranged on the outer diameter near the two ends of the adapter 3 are connected as a whole, and the threaded interface of the oil outlet is an external threaded interface (such as Figure 7 Shown adapter 3); 2. The switch 5 is connected to the threaded joint of the oil outlet of the adapter 3 through the conduit 7 (such as figure 2 3. The oil inlet hydraulic interface of the aircraft brake device is located on the end face of the cylinder block 6, and there is a through hole near the periphery of the pressure plate 2, or a gap or a notch on the periphery to accommodate the connection of the oil inlet nozzle (such as Figure 8 to Figure 10 Platen 2) shown.

[0070] see figure 2 , Figure 4 , Figure 7 to Figure 11 . The cylinder block cleaning tool for the aircraft braking device provided in this embodiment may include: an adapter 3, a pressure plate 2, a fixing plate 4, a bolt 1, a switch 5, and t...

Embodiment 3

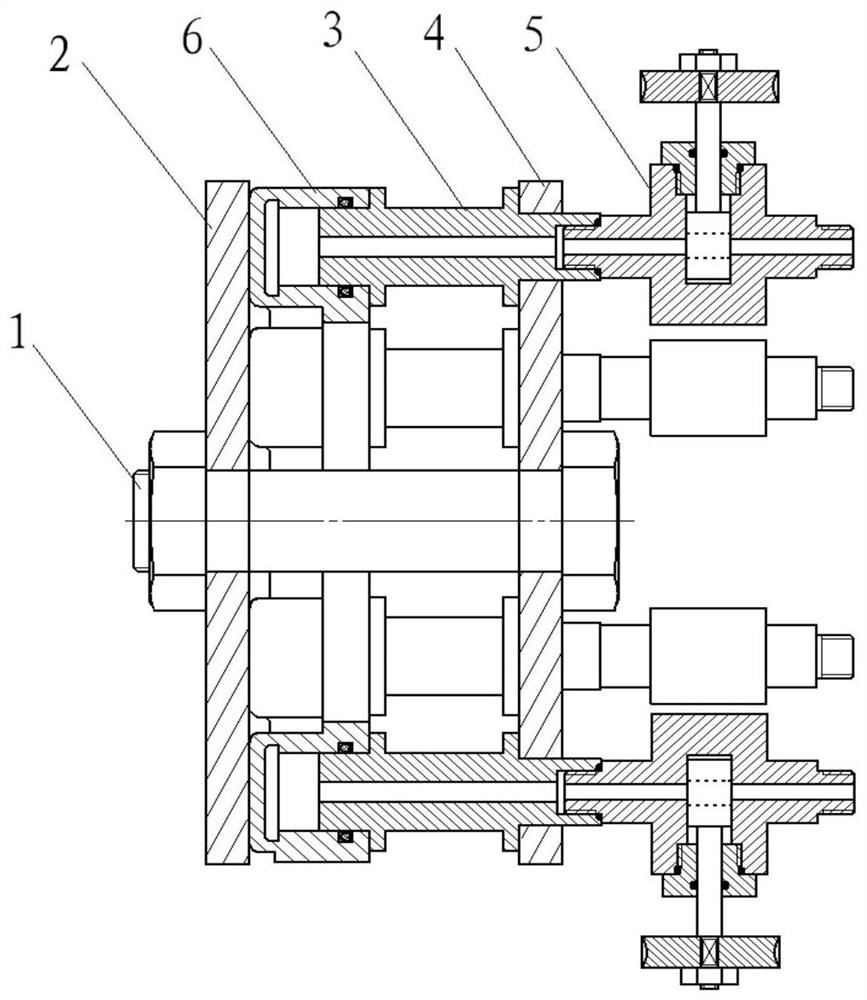

[0082] see Figure 3 to Figure 4 , Figure 6 , Figure 8 to Figure 11 . The difference between this embodiment and Embodiment 1 is that the cleaned aircraft brake device cylinder block 6 piston hole does not have a piston bushing, and the piston is directly installed in the cylinder block 6 piston hole. There are protrusions on the end surface of the cylinder block 6 of the aircraft brake device, and the oil inlet 8 is located on the end surface of the cylinder block 6, and the number is 2. For this reason, a through hole is opened near the periphery of the pressure plate 2, or a gap or a notch is opened on the periphery of the pressure plate 2. To accommodate the screw plug connected to the oil inlet nozzle and to avoid blocking the other oil inlet.

[0083] The cylinder block cleaning tool for the aircraft braking device provided in this embodiment may include: an adapter 3, a pressure plate 2, a fixing plate 4, a bolt 1, a switch 5, and the like. The number of pieces of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com