Assembling system for motor vehicle parts

An assembly system and motor vehicle technology, applied in assembly machines, metal processing, metal processing equipment, etc., can solve the problems of unguaranteed product quality, low production and assembly efficiency, high labor intensity, and achieve quality assurance and improve production. Efficiency, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

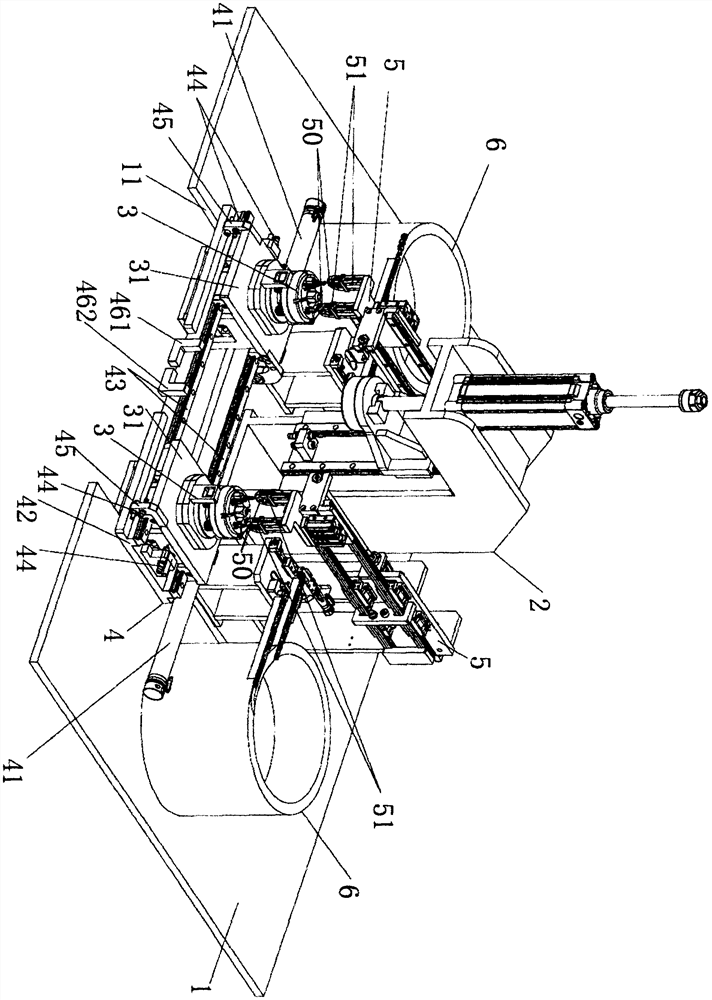

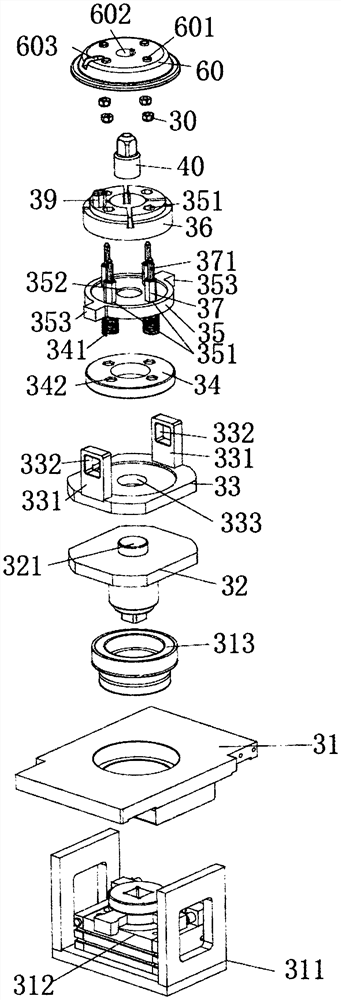

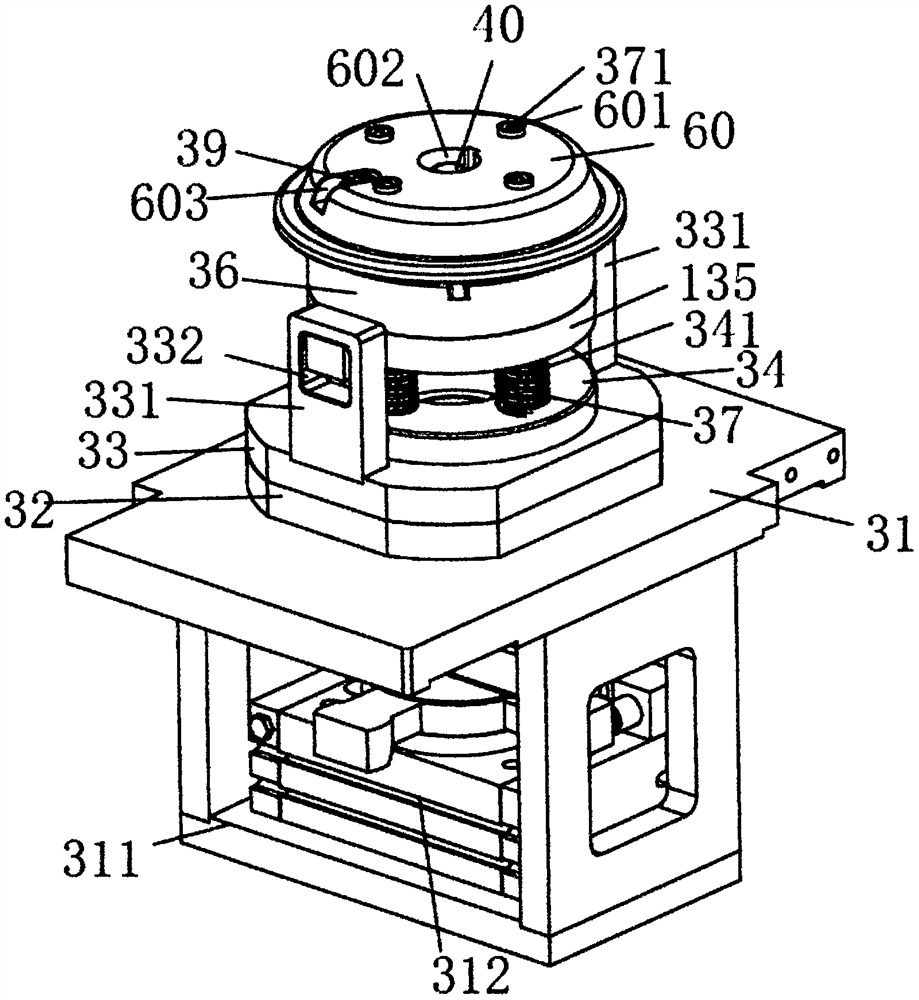

[0023] Such as Figure 1-Figure 8 As shown, the assembly system of motor vehicle parts described in this embodiment includes a substrate 1, an extrusion mechanism 2, and feeding mechanisms 5 located on the left and right sides of the extrusion mechanism 2, and the positions of the two feeding mechanisms 5 are provided with nuts. The feeding mechanism 6 and the front side of the extruding mechanism 2 are equipped with a translation mechanism 4, and both ends of the translation mechanism 4 are slidingly installed with an assembly mechanism 3, and the two assembly mechanisms 3 are respectively located below the feeding and discharging ends of the two feeding mechanisms. , the extrusion mechanism, the two feeding mechanisms, the two feeding mechanisms and the translation mechanism are all installed on the base plate; during assembly, the nut feeding mechanism feeds the nut to the position of the discharge end, and the feeding mechanism drives its feeding manipulator to put the nut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com