Mechanical arm autonomous calibration method based on visual measurement

A calibration method and visual measurement technology, applied to manipulators, program-controlled manipulators, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

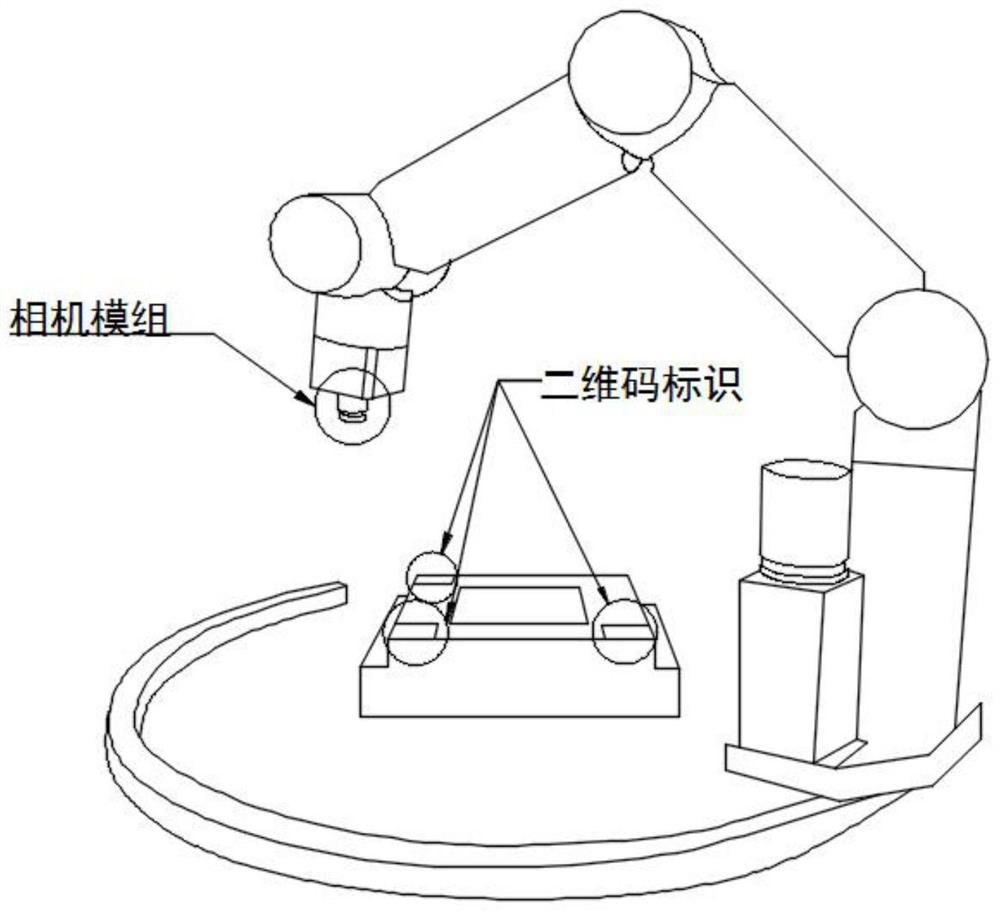

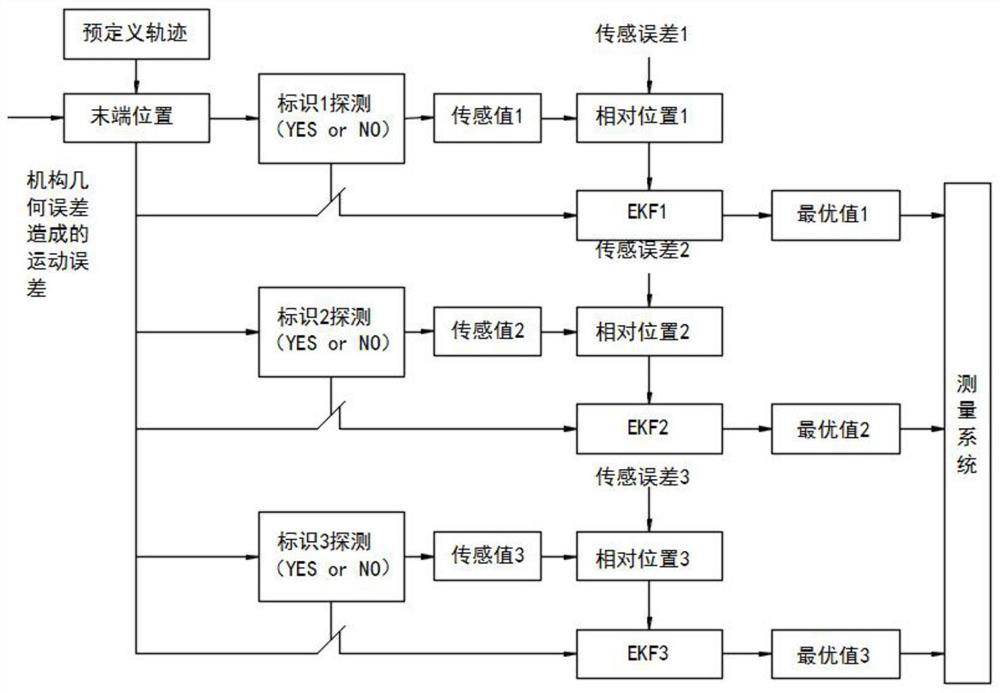

[0112] refer to Figure 1-8 , an autonomous calibration method for manipulators based on visual measurement, including the following steps:

[0113] Step 1: Build an unsteady multi-sensor manipulator vision system;

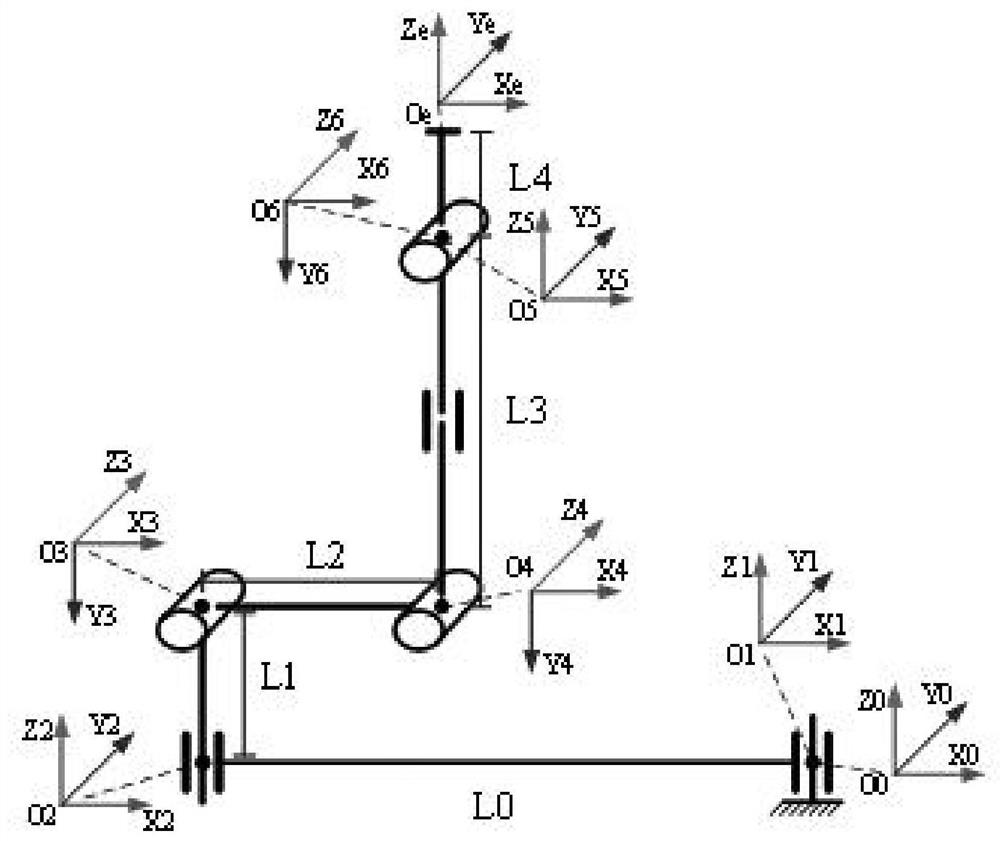

[0114] Taking the life science glove box robotic arm of China Space Station as the research platform, in order to obtain higher positioning accuracy and improve the fit between the model and the actual geometric configuration of the robotic arm, a more stringent improved DH model was established, and a Group of angles, to represent the error angle of the connecting rod rotating around the y-axis, preferably, all angle values are zero; axis 1 is an arc guideway, in the mechanical model, it is abstracted as a rotation axis with a virtual link, the The length of the connecting rod is equal to the radius of the arc guide rail. During the preparation process, the positions of the three two-dimensional code marking points in the base coordinate system are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com