M12 large-size silicon wafer cutting method

A silicon wafer cutting, large-size technology, used in manufacturing tools, stone processing equipment, fine working devices, etc., can solve the problem of not being able to meet the requirements of M12 large-size wafer cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

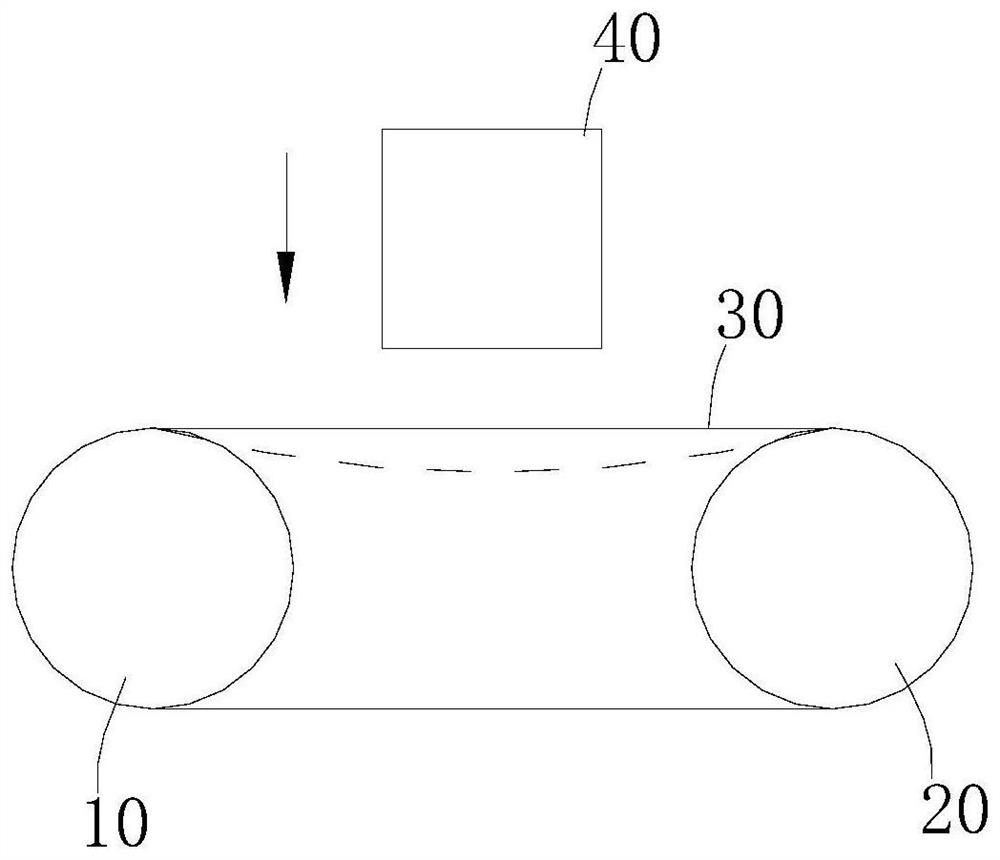

Image

Examples

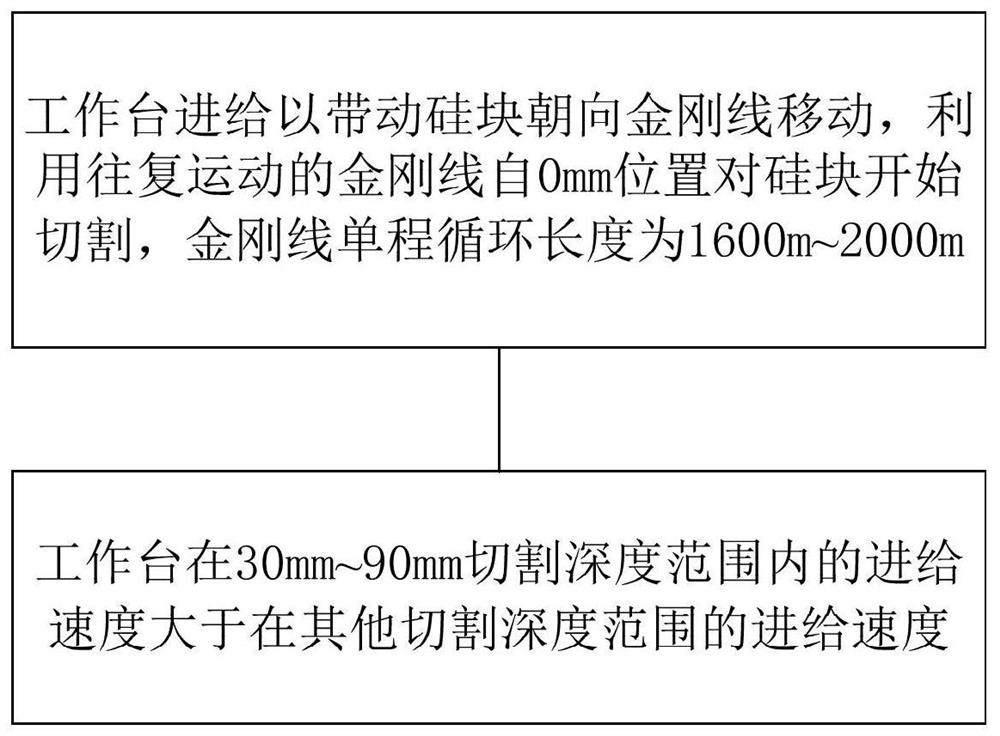

Embodiment 1

[0048] The diamond wire reciprocates, the one-way cycle length is 1600m, and the diamond wire speed is 35m / s. The initial feed speed of the table is 1mm / min; the feed speed of the table within the range of 0mm~30mm cutting depth is 1.2mm / min; the feed speed of the table within the range of 30mm~90mm cutting depth is 2.9mm / min; 90mm The feed speed of the table within the range of 180mm cutting depth is 2.7mm / min; the feed speed of the table within the range of 180mm~218mm cutting depth is 0.1~2.3mm / min. The cutting fluid temperature is 19°C. Cutting under the above parameter conditions, there is basically no disconnection. In addition, the TTV value of the silicon wafer is ≤25um, which meets the index requirements of the TTV value ≤30um.

Embodiment 2

[0050] The diamond wire reciprocates, the one-way cycle length is 1850m, and the diamond wire speed is 38m / s. The initial feed speed of the table is 1mm / min; the feed speed of the table within the range of 0mm~30mm cutting depth is 1.8mm / min; the feed speed of the table within the range of 30mm~90mm cutting depth is 2.95mm / min; 90mm The feed speed of the table within the range of ~180mm cutting depth is 2.62mm / min; the feed speed of the table within the range of 180mm~2180mm cutting depth is 0.1~2.2mm / min. The cutting fluid temperature is 20°C. Cutting under the above parameter conditions, there is basically no disconnection. In addition, the TTV value of the silicon wafer is ≤27um, which meets the index requirements of the TTV value ≤30um.

Embodiment 3

[0052] The diamond wire reciprocates, the one-way cycle length is 2000m, and the diamond wire speed is 40m / s. The initial feed speed of the table is 1mm / min; the feed speed of the table within the range of 0mm~30mm cutting depth is 2.2mm / min; the feed speed of the table within the range of 30mm~90mm cutting depth is 3mm / min; The feed speed of the table within the range of 180mm cutting depth is 2.7mm / min; the feed speed of the table within the range of 180mm~218mm cutting depth is 0.1~2.15mm / min. The cutting fluid temperature is 21°C. Cutting under the above parameter conditions, there is basically no disconnection. In addition, the TTV value of the silicon wafer is ≤29um, which meets the index requirements of the TTV value ≤30um.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com