Automatic nozzle welding machine for flexible packaging bags

A flexible packaging bag, welding nozzle machine technology, applied in packaging, transportation and packaging, bag making operations, etc., can solve the problems of slow production efficiency, high labor cost, low production efficiency, etc., to reduce labor costs, improve production efficiency, The effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The scheme of this application is further described in conjunction with the accompanying drawings as follows:

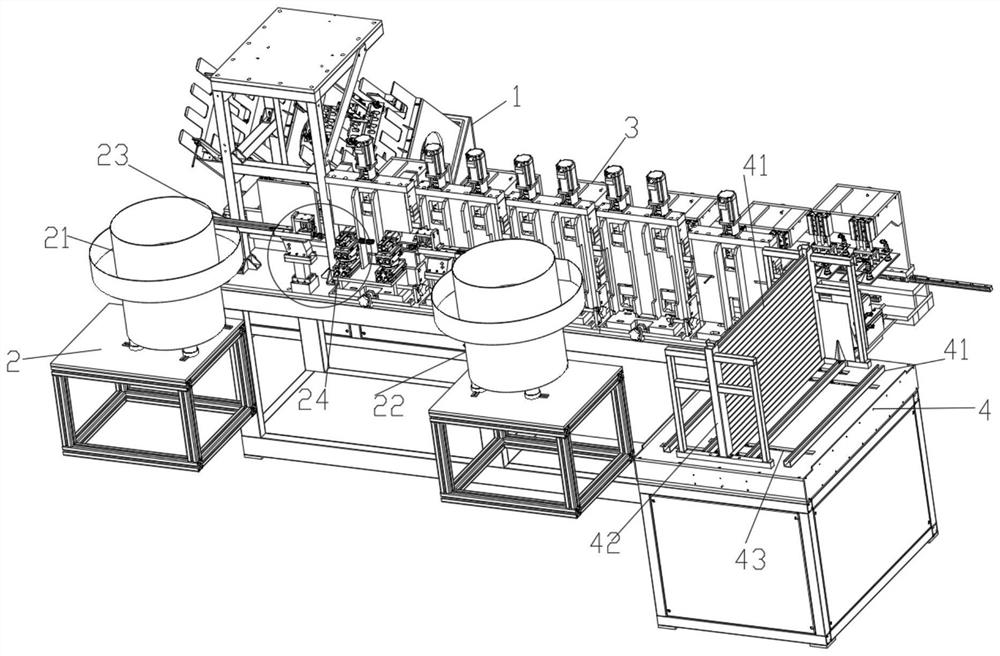

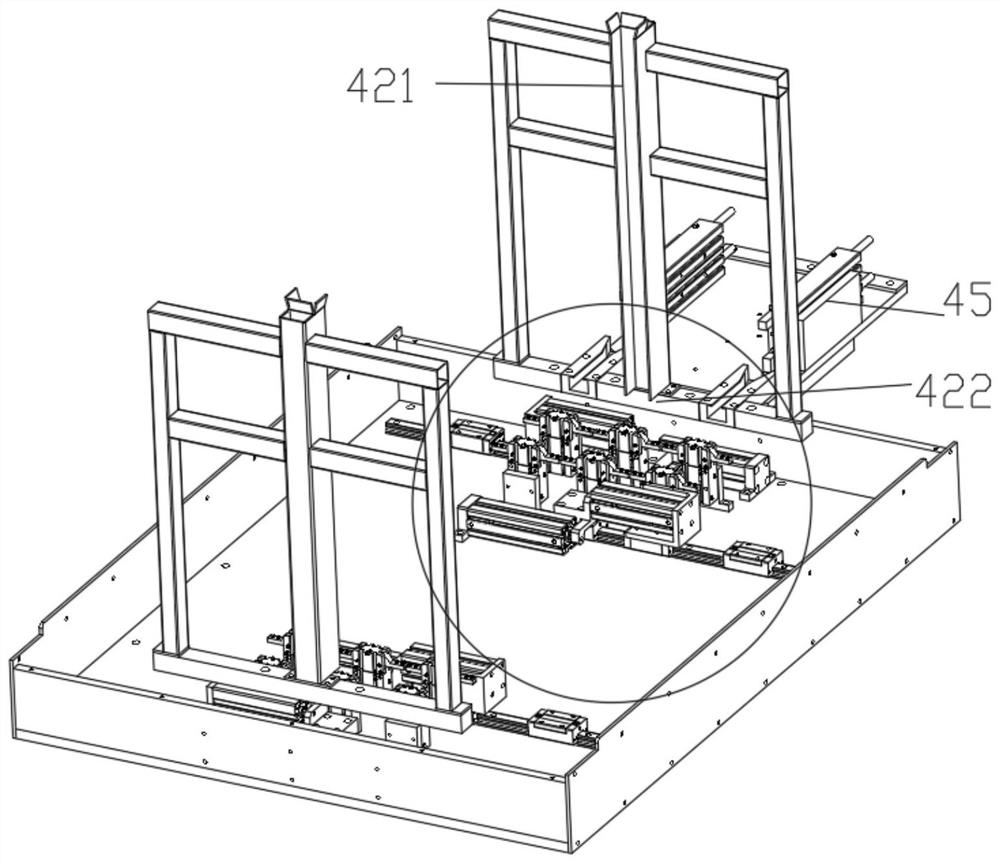

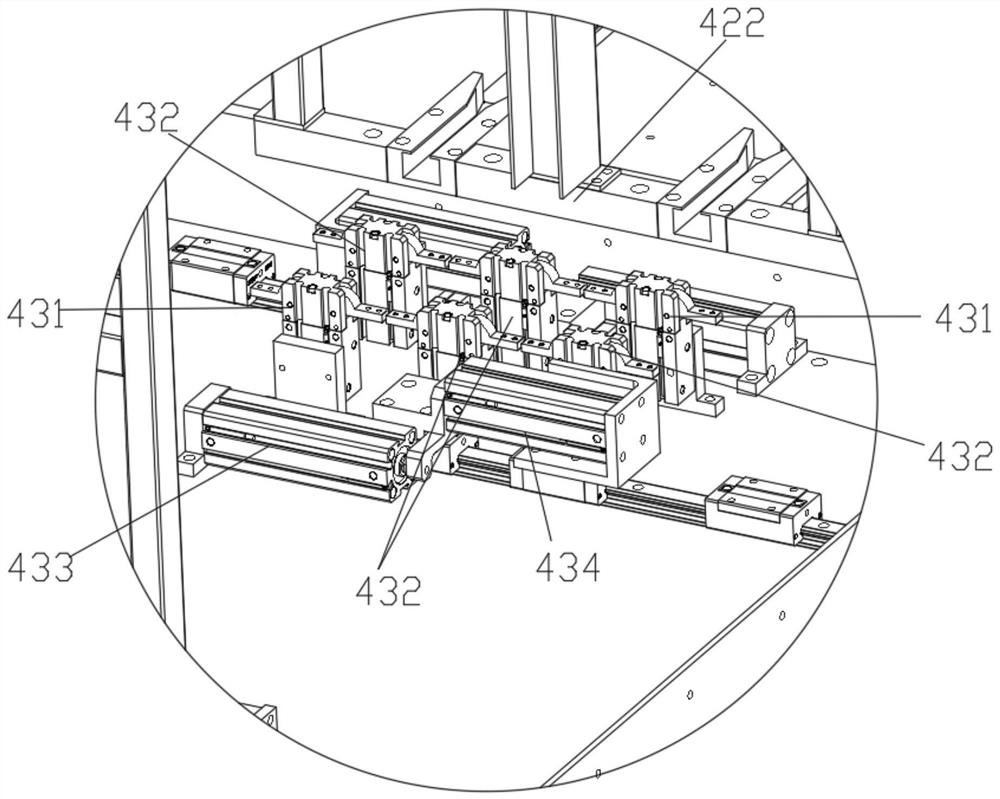

[0026] See attached Figure 1-10 An automatic nozzle welding machine for flexible packaging bags, comprising a bag body feeding mechanism 1, a suction nozzle feeding mechanism 2, a nozzle pressing mechanism 3 and a feeding mechanism 4, the bag body feeding mechanism 1 sends the bag body to the nozzle pressing mechanism 3. The nozzle feeding mechanism 2 sends the nozzle to the nozzle pressing mechanism 3, and the nozzle pressing mechanism 3 installs the nozzle on the bag body, and the unloading structure 4 includes a storage tank 41, a storage tank installation area 42. The storage tank conveying mechanism 43, the storage tank 41 is superimposed on the storage tank installation area 42, the storage tank installation area 42 is provided with two opposite installation slots 421, the upper end opening of the installation slot 421 and one side or two sides of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com