High-transparency low-haze BOPET anti-fog film and preparation method thereof

An anti-fog film, low haze technology, applied in chemical instruments and methods, coatings, layered products, etc., can solve the problems of blurred vision of users, affect visual effects, low anti-fog performance, etc., and achieve excellent anti-fog performance. High performance, safe and reliable, high gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

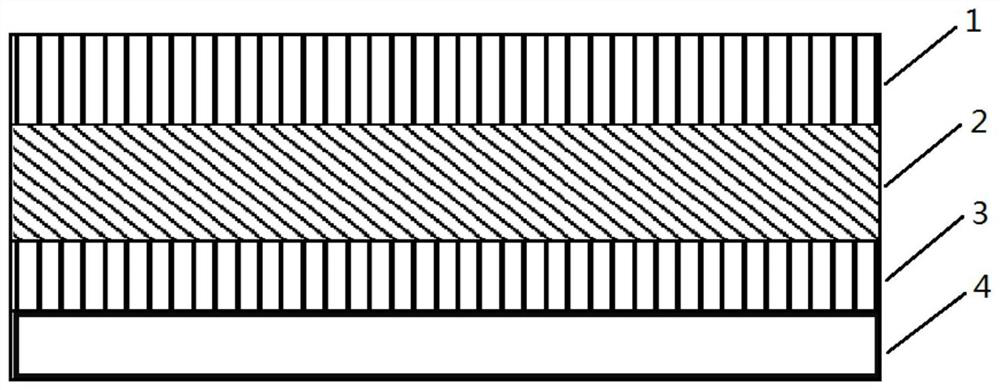

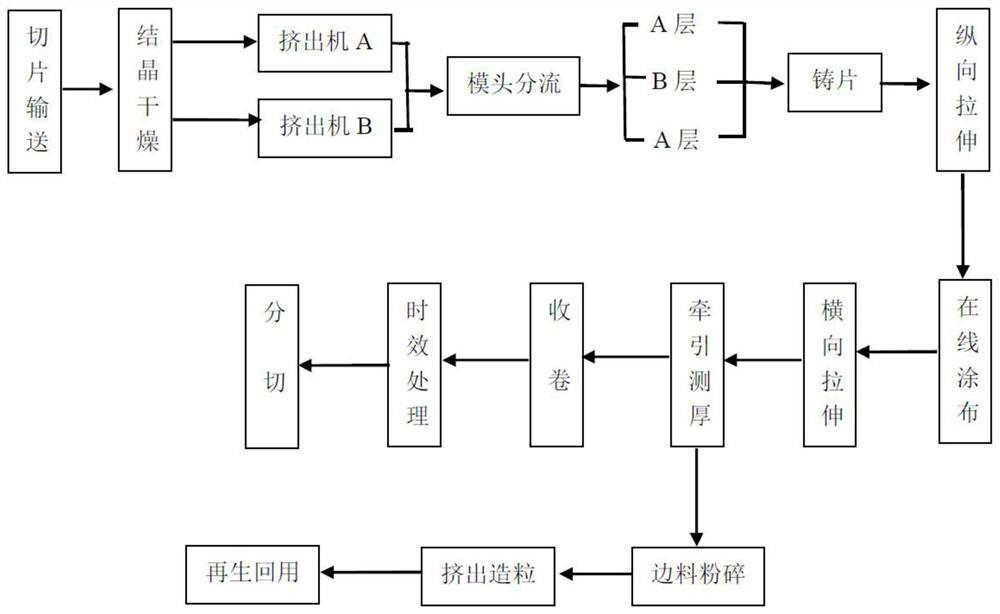

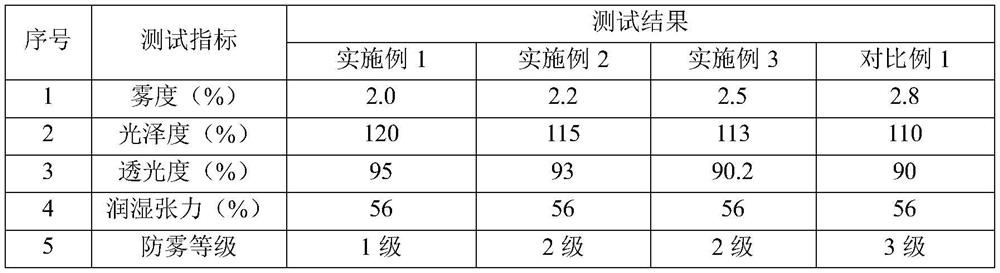

[0043] A polyester anti-fog film prepared by biaxial stretching process and on-line coating of anti-fog liquid. The ratio of raw materials and masterbatch: A layer is composed of raw material polyester and anti-adhesive masterbatch in a mass ratio of 85:15. The B layer is composed of raw polyester. The moisture content of the raw material masterbatch after drying is <20ppm. The three-layer co-extrusion percentage example is A layer 5%×2, B layer 90%. The extruder barrel, die head, MDO, and TDO heating temperatures were 220°C, 275°C, 80°C, and 90°C, respectively. The production line speed is 28m / min, the longitudinal stretch ratio is 2.5, and the transverse stretch ratio is 3.0. On-line trimming and off-cut recycling is not on-line utilization. The anti-reflection and anti-fog water-based coating solution for online coating is diluted in a volume ratio of 1 part of anti-fog solution, 1 part of water and 3 parts of ethanol. The coating thickness is 13um (wet). The corona in...

Embodiment 2

[0046] A polyester anti-fog film prepared by biaxial stretching process and on-line coating of anti-fog liquid. The ratio of raw materials and masterbatch: A layer is composed of raw material polyester and anti-adhesive masterbatch in a mass ratio of 82:18. The B layer is composed of raw polyester. The moisture content of the raw material masterbatch after drying is less than 20ppm. The three-layer co-extrusion percentage example is A layer 6%×2, B layer 88%. The extruder barrel, die head, MDO, and TDO heating temperatures were 250°C, 285°C, 82°C, and 95°C, respectively. The production line speed is 30m / min, the longitudinal stretch ratio is 2.8, and the transverse stretch ratio is 3.5. On-line trimming and off-cut recycling is not on-line utilization. The anti-reflection and anti-fog water-based coating solution for online coating is diluted in a volume ratio of 1 part of anti-fog solution, 1.5 parts of water, and 2.5 parts of ethanol. Coating thickness 12um (wet). The c...

Embodiment 3

[0049] A polyester anti-fog film prepared by biaxial stretching process and on-line coating of anti-fog liquid. The ratio of raw materials and masterbatch: A layer is composed of raw material polyester and anti-adhesive masterbatch in a mass ratio of 80:20. The B layer is composed of raw polyester. The moisture content of the raw material masterbatch after drying is <20ppm. The three-layer co-extrusion percentage example is A layer 8%×2, B layer 84%. The extruder barrel, die head, MDO, and TDO heating temperatures are 260°C, 280°C, 85°C, and 98°C, respectively. The production line speed is 32m / min, the longitudinal stretch ratio is 3.0, and the transverse stretch ratio is 3.8. On-line trimming and off-cut recycling is not on-line utilization. The anti-reflection and anti-fog water-based coating solution for online coating is diluted in a volume ratio of 1 part of anti-fog solution, 2 parts of water and 2 parts of ethanol. Coating thickness 10um (wet). The corona intensity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com