Steering drive axle and forklift

A technology for driving axles and steering cylinders, which is applied in the directions of axles, wheels, and vehicle components, and can solve problems such as inability to turn, get stuck in a quagmire, and fail to realize normal driving, etc., and achieve the effect of flexible turning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

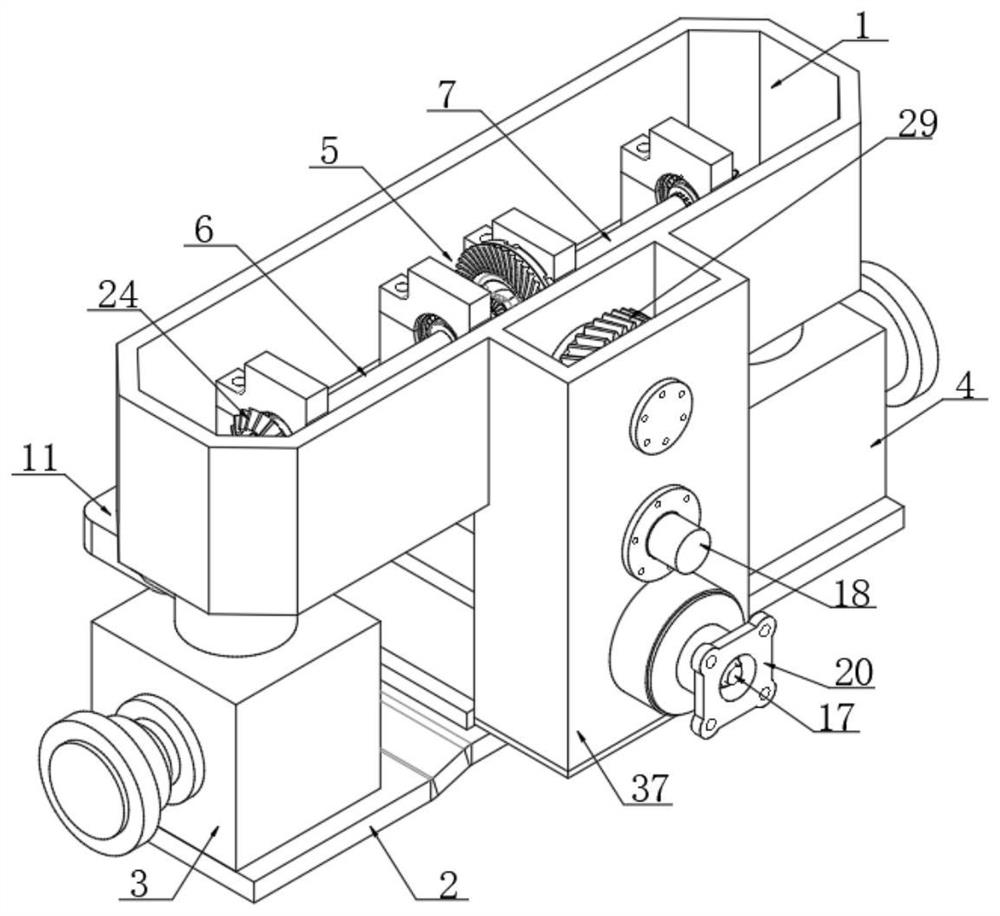

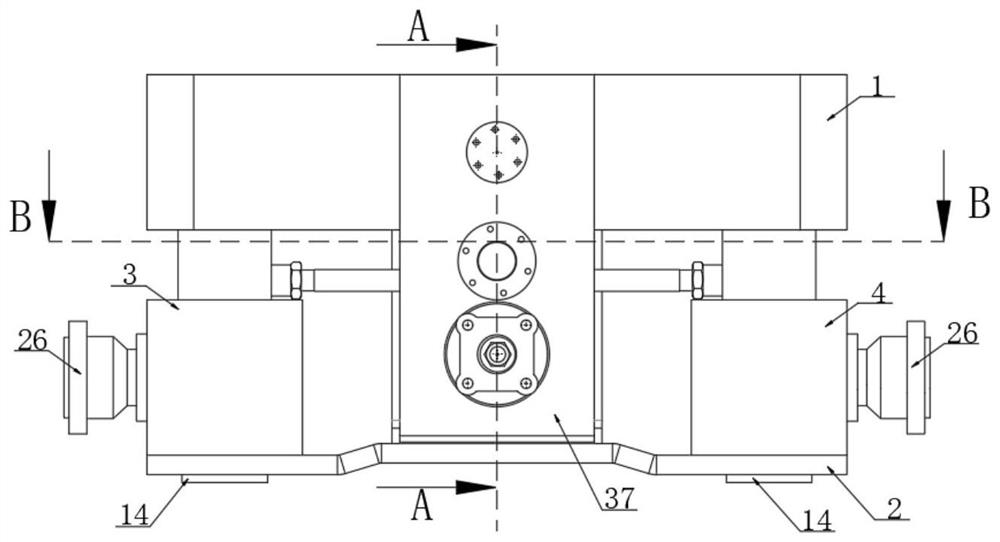

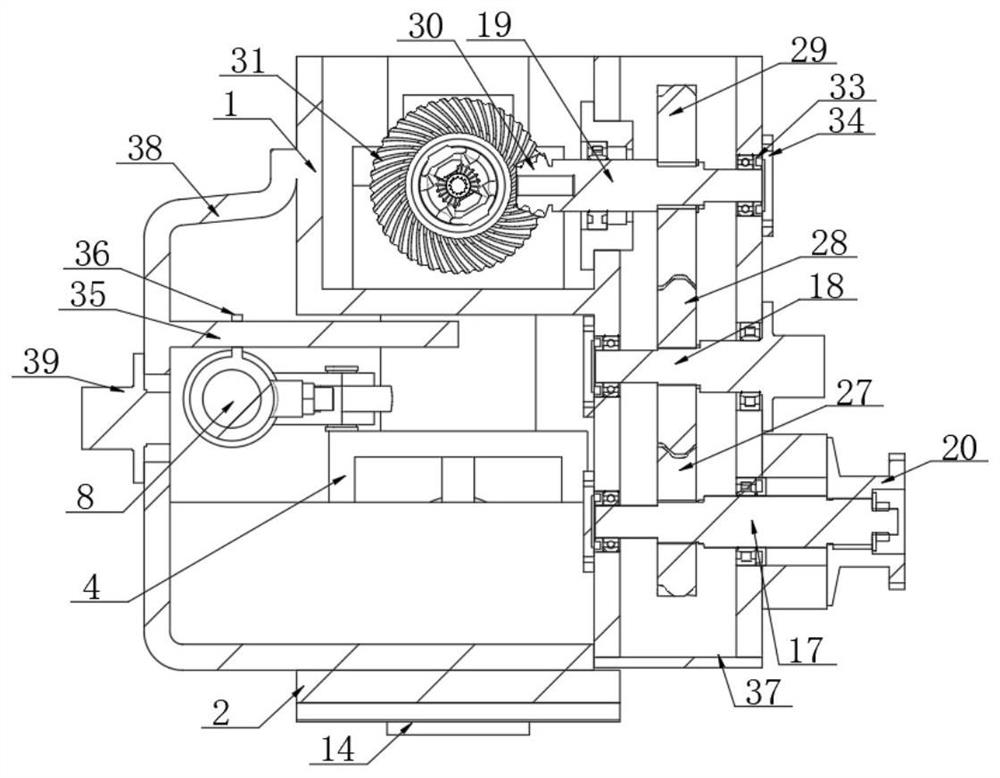

Method used

Image

Examples

Example Embodiment

[0076] Example 2, as Figure 23-Figure 26 As shown, the cylinder body of the steering oil cylinder is hingedly mounted on the housing, and the piston rod of the steering oil cylinder is connected to the left steering box body or the right steering box body through the arm, and the left steering box body is connected by The synchronizing rod 43 is connected with the right steering box. The left and right steering boxes are respectively provided with left and right ear plates. The cylinder body of the steering oil cylinder is hinged with the housing, specifically through the hinge shaft 42 . The free end of the piston rod of the steering oil cylinder is hinged with one end of the crank arm, the other end of the crank arm is hinged with a right ear plate of the right steering box, and the left and right steering boxes are connected by a synchronizing rod. The crank arm is hinged with another right ear plate of the right steering box body, and the other end is hinged with the le...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap