Rolling body

A rolling body and main body technology, applied in the tool field of automatic roll-up protection net, can solve the problems of affecting mining economy, sliding shoe wear, and great influence, and achieve good overall interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

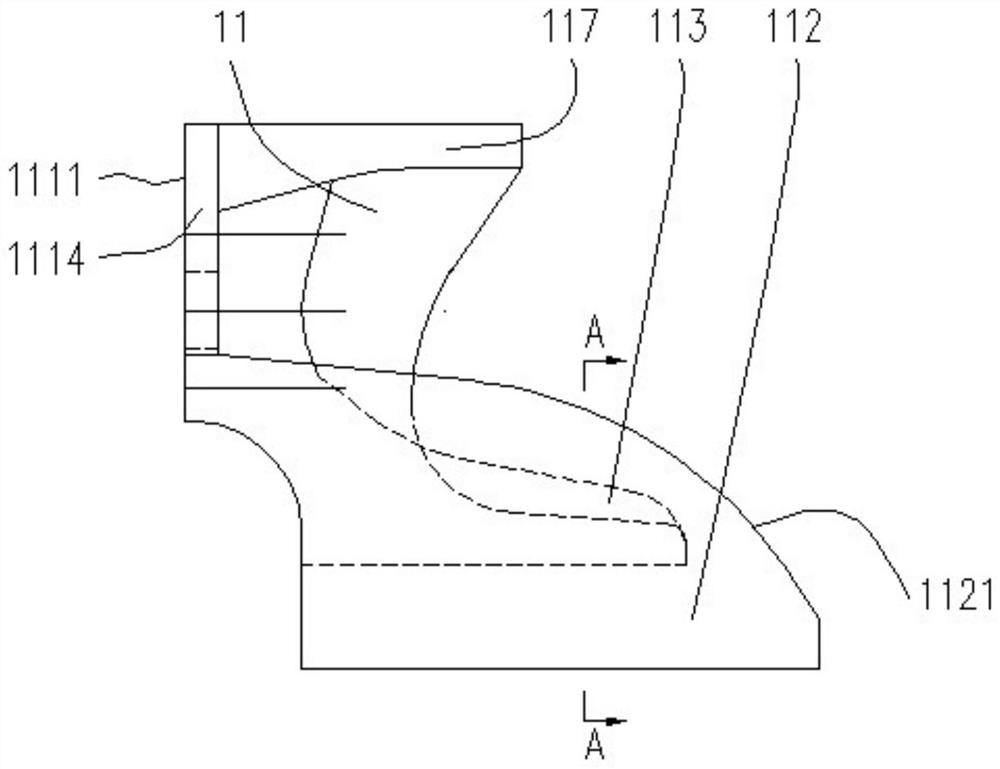

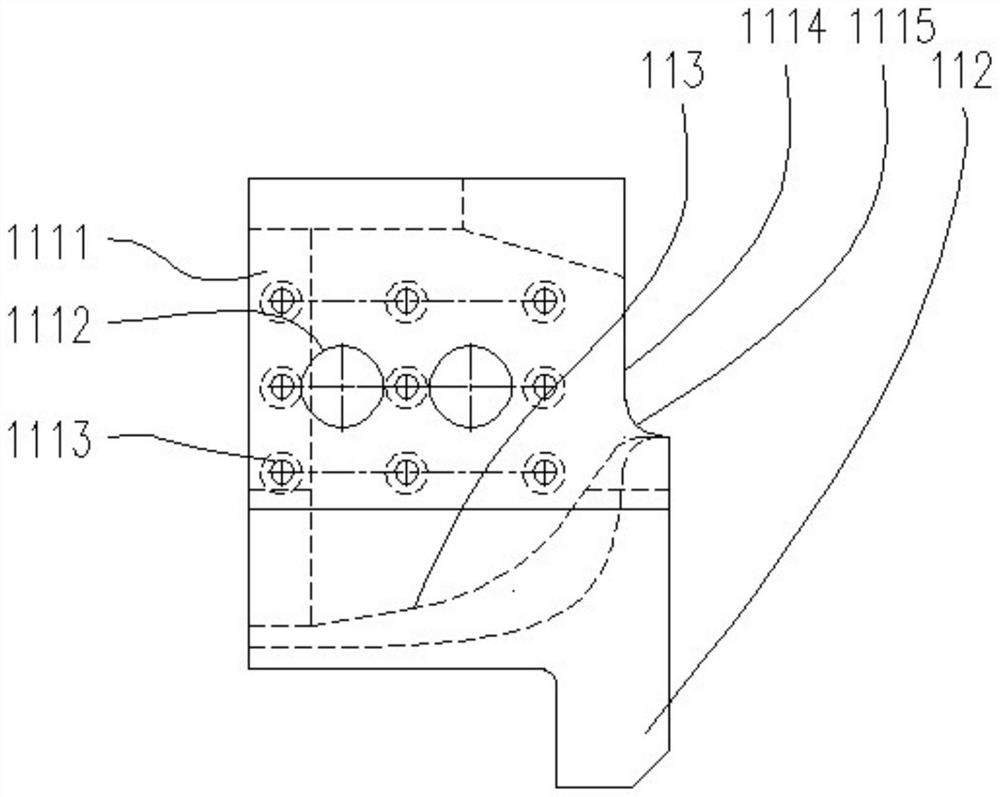

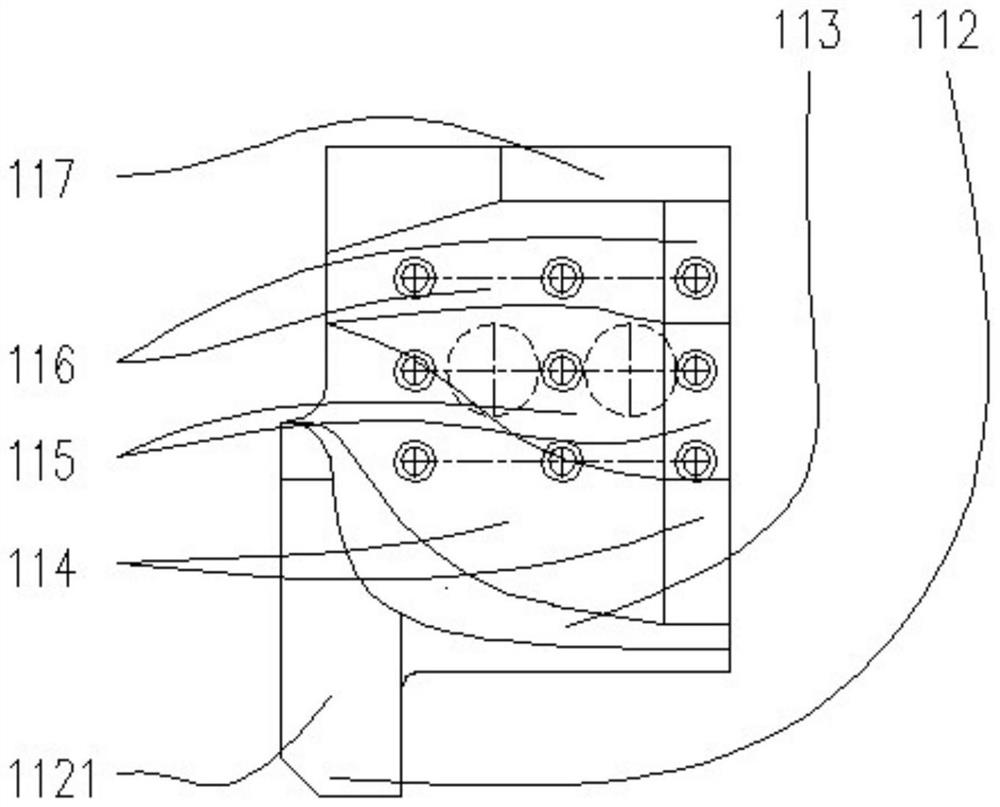

[0038] The invention discloses a rolling body 1, such as Figure 1-12 As shown, it is a "bucket"-shaped structural member. For the convenience of expression, this paper refers to the end of the "bucket" where the shovel mouth and shovel back are located, respectively as the far end and the near end. The near end is provided with a detachable installation interface structure. It is used for the fixed connection between the rolling body and the walking box of the mining machine. The working surface of the main body 11 (i.e. the inner surface of the "bucket") is a smooth space curved surface concave in the middle. A smooth concave curved surface with low front and high rear, the part of the working surface of the main body near the near end is a smooth concave curved surface with high front and low rear, the bottom surface of the main body is located above the track 42 of the conveyor 4, and the upper part of the rolling body is set There is a roof overhanging from the near end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com