Surface etching device for etching glass

A surface etching and glass technology, which is applied in cleaning methods and utensils, cleaning flexible objects, chemical instruments and methods, etc., can solve the problems of complex structure and reduce the efficiency of glass disassembly and assembly, so as to increase functionality, improve practicability and work The effect of efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

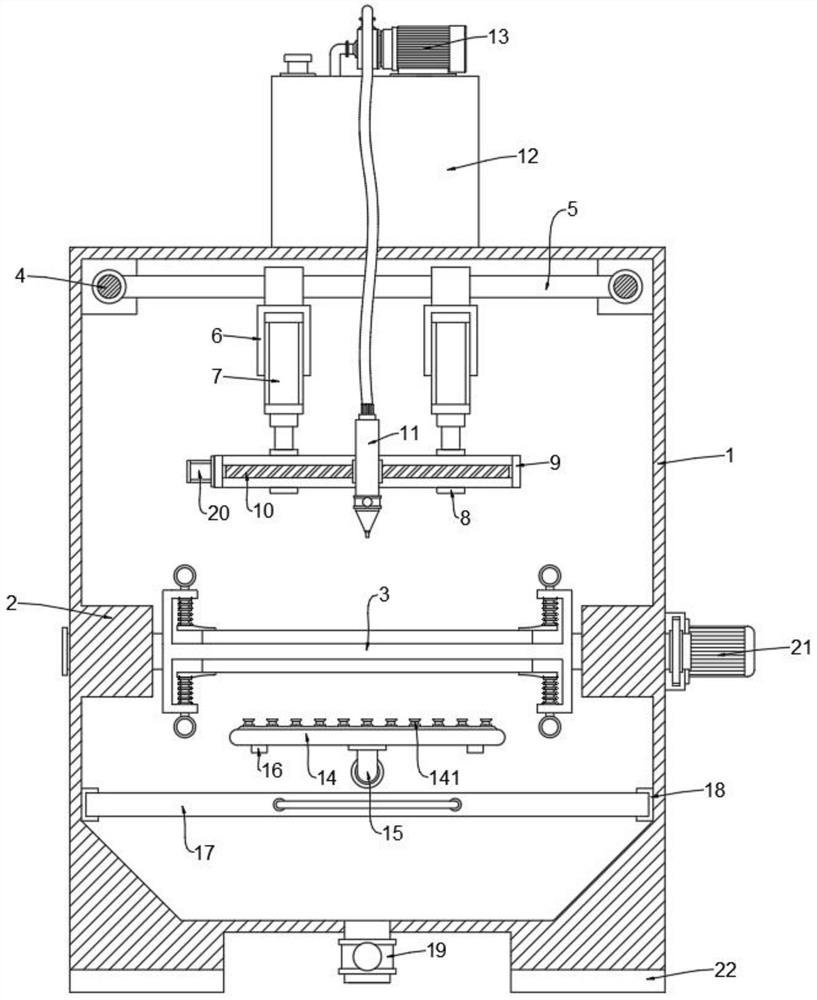

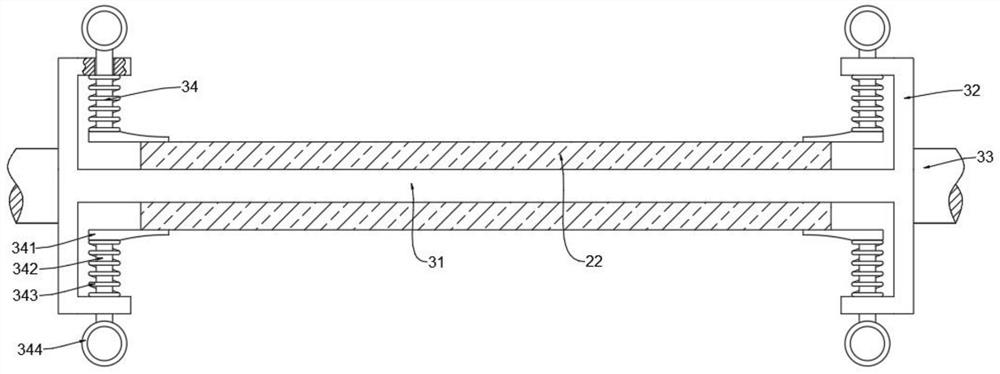

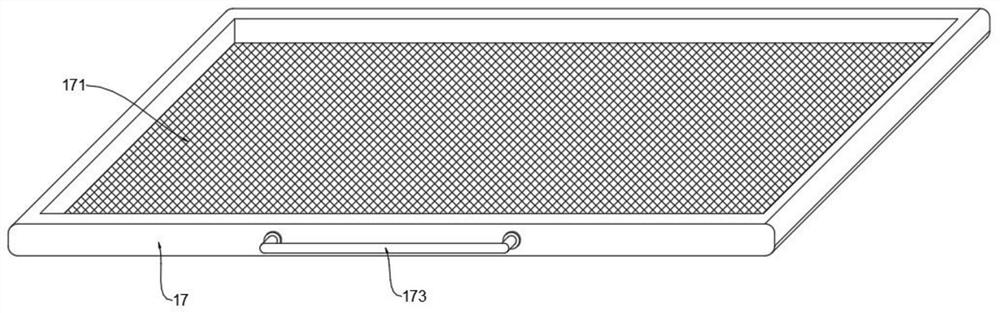

[0026] see Figure 1-5 , an embodiment provided by the present invention: a surface etching device for etching glass, including a casing 1, receiving platforms 2 are arranged on both sides inside the casing 1, and a clamping mechanism is installed between the two receiving platforms 2 3. The clamping mechanism 3 includes a receiving plate 31, a support frame 32, a connecting shaft 33 and a pressing member 34. The supporting frame 32 is arranged on the top and bottom of both ends of the receiving plate 31, and is integrated with the receiving plate 31. The connecting shaft 33 It is arranged at both ends of the receiving plate 31, and has an integrated structure with t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap