Integrated industrial preparation device for carbonized regenerated micro-powder

A preparation device and technology for regenerated fine powder, applied in the field of environmental protection equipment, can solve the problems of optimal control of carbonization conditions of unregenerated aggregate pretreatment of recycled aggregate, integrated production of unformed recycled fine powder, etc., so as to improve the pretreatment efficiency and the degree of automation High, improve the effect of screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

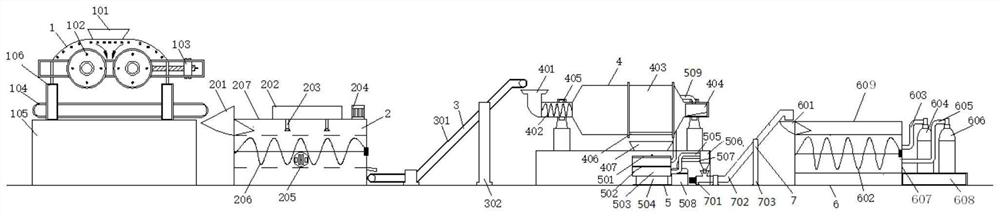

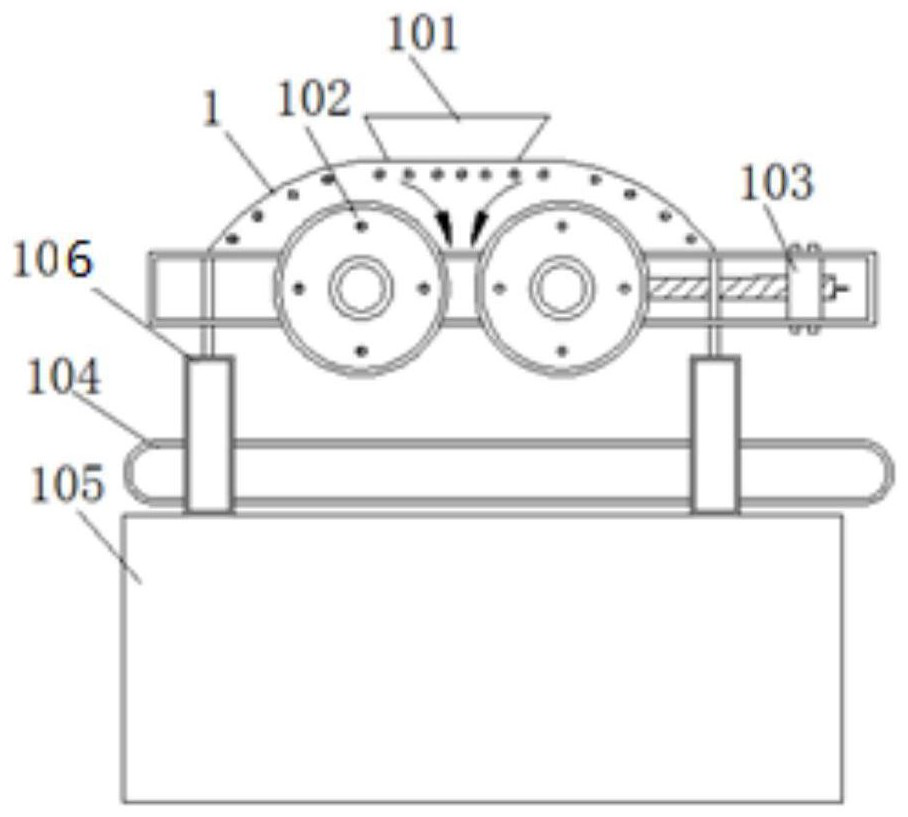

[0032] refer to Figure 1 to Figure 7 An embodiment of an integrated industrialized preparation device for carbonized regenerated fine powder of the present invention will be further described.

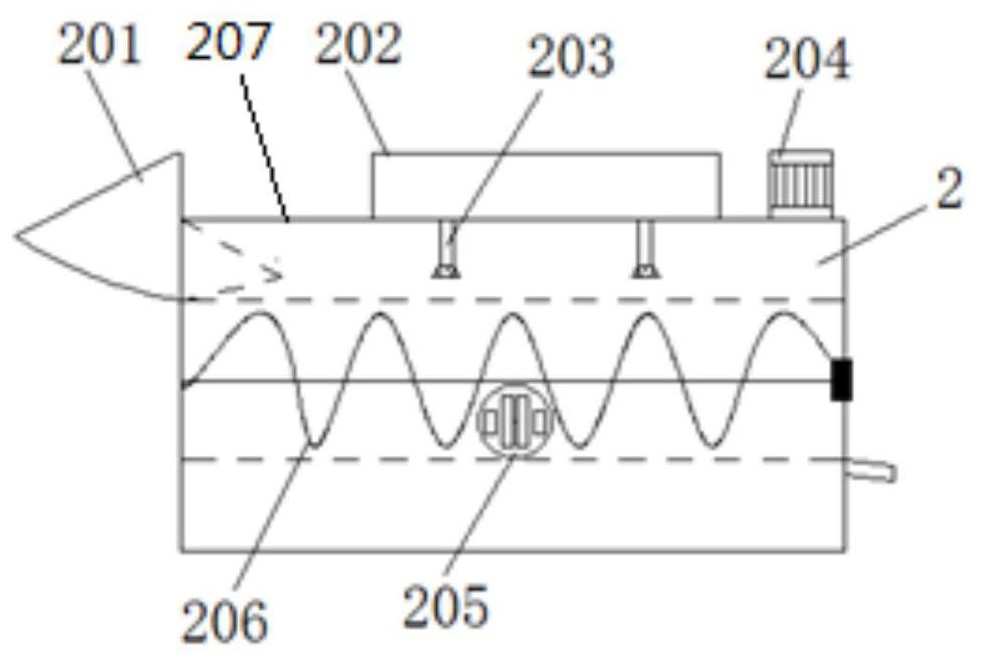

[0033]An integrated industrial preparation device for carbonized regenerated micropowder, including a crushing device 1, a performance-improving pretreatment device 2, a first conveying device 3, a ball milling device 4, a screening device 5, a second conveying device 7 and a low humidity gain The carbonization system device 6, the performance improvement pretreatment device 2 includes a pretreatment box 207, the pretreatment box 207 is provided with a first material inlet 201 matched with the output end of the crushing device 1, and the pretreatment box 207 The top of the top is provided with a pretreatment solution storage box 202, and the pretreatment solution storage box 202 is connected with a number of nozzles 203 located in the pretreatment box 207, and the first spiral blade m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com