Coaxial annular multi-beam powder feeding nozzle

A ring-shaped, powder-feeding technology, which is applied in metal material coating process, coating and other directions, to achieve the effect of improving utilization rate, improving flexibility, and durable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

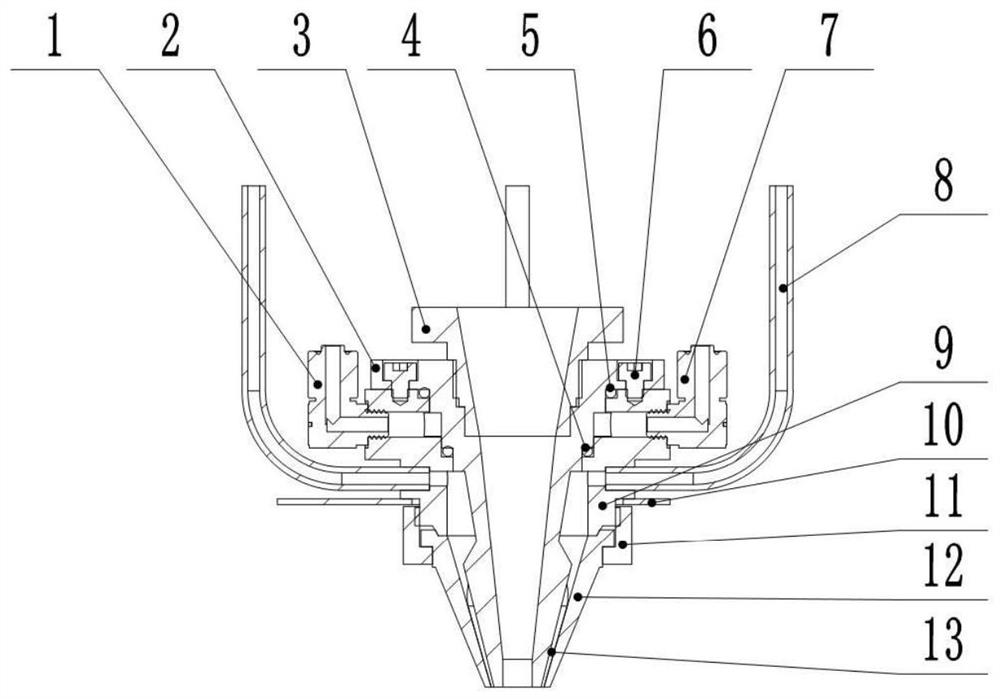

[0030] DRAWINGS The present invention will be further described, to enable those skilled in the art to more clearly understand the invention, but without thereby restricting the scope of the present invention.

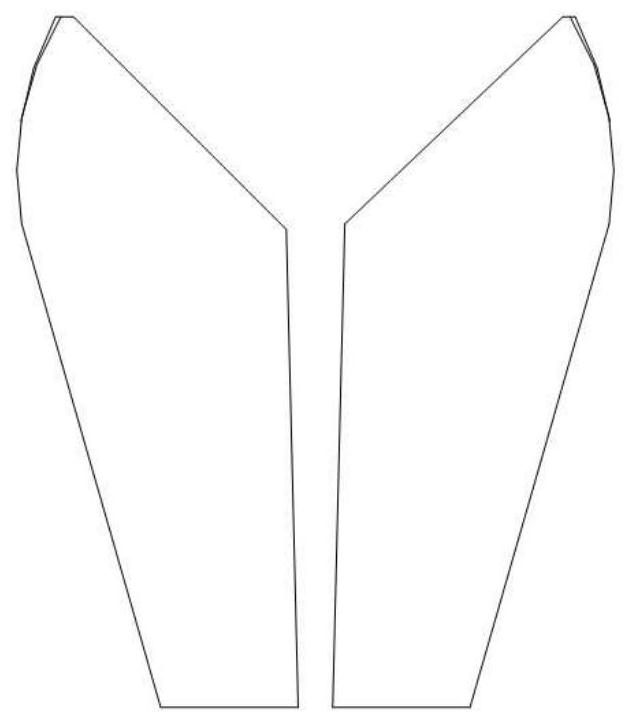

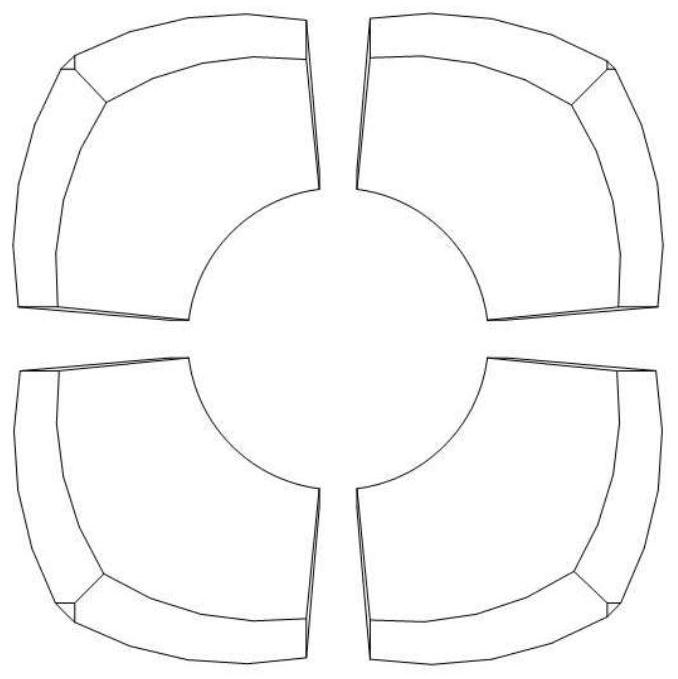

[0031] Append figure 1 , The coaxial annular beam of the present invention is a multi-powder nozzle, comprising: a water intake 1, the core 2, the connection base 3, a first sealing ring 4, the second seal ring 5, a screw 6, water outlet 7 powder feed tube 8, body 9, the light blocking plate 10, threaded sleeve 11, the housing 12 and the separating baffle plate 13.

[0032] The body 1 is connected with the water inlet and a water outlet 7. In particular the inlet connection and a water outlet 7 has an external thread, the fitting body 9 with an internal thread of the bore hole, the inlet connection and the water outlet 7 of the body 1 by a threaded connection 9, 1 and the inlet connection and the water outlet 7 are connected to both sides of the main body 9. Said inner cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com