Wear-resistant paper production device

A production device and wear-resistant paper technology, which is applied to paper, papermaking, paper machines, etc., can solve the problems of poor clarity, low wear resistance, and uneven distribution of abrasive grains, so as to increase the smoothing area, realize clean, smooth even effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions in the embodiments of the present invention will be clearly and completely described below.

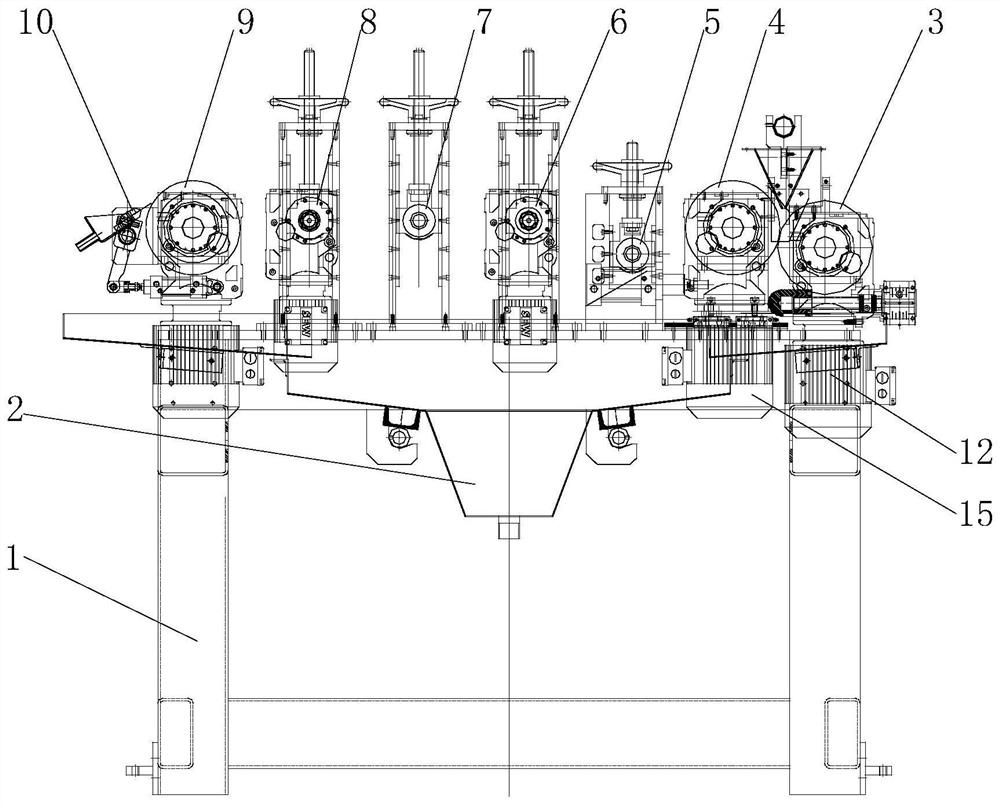

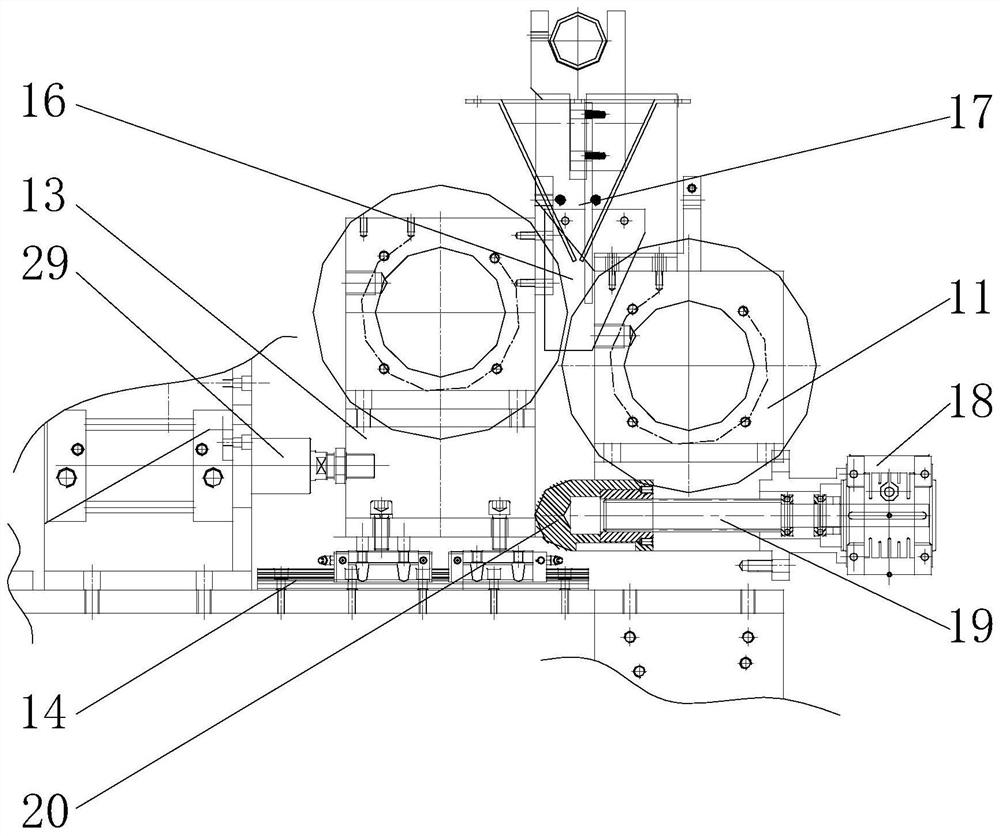

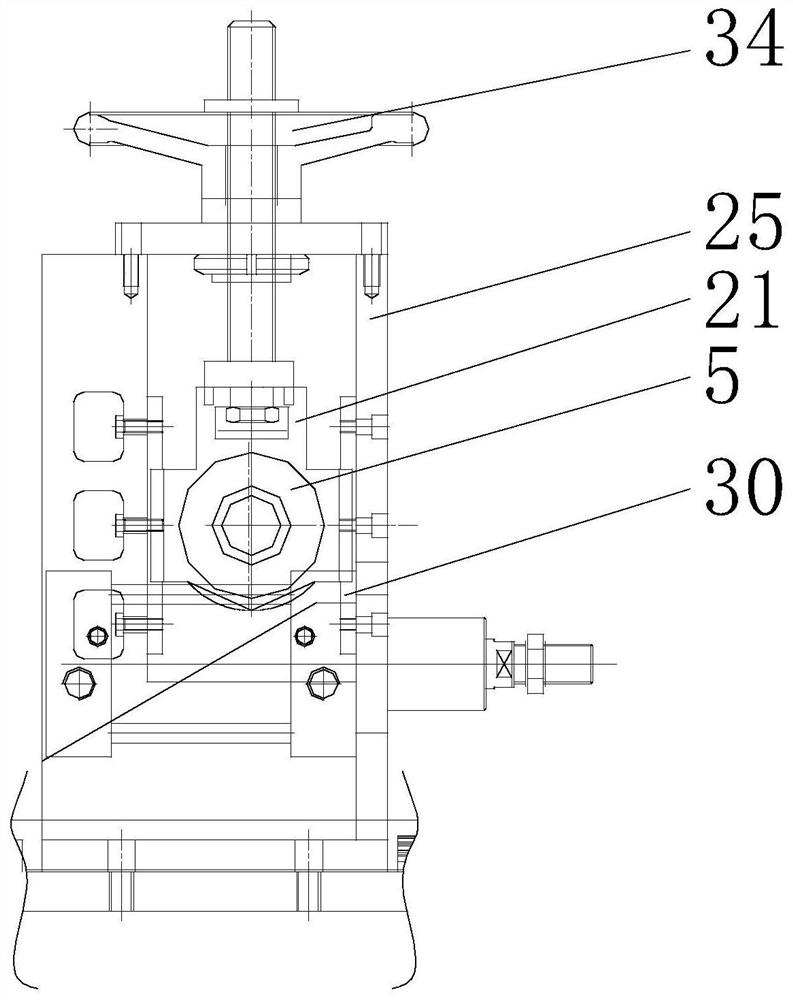

[0021] Such as Figure 1-7 As shown, a wear-resistant paper production device includes a frame 1, which is provided with a wear-resistant liquid recovery tank 2, and the frame 1 is sequentially provided with a spraying fixed roller 3, a spraying movable roller from the right side to the left side. Roller 4, lower smoothing roller one 5, upper smoothing roller one 6, lower smoothing roller two 7, upper smoothing roller two 8, paper output roller 9 and scraper 10, the two ends of the spraying fixed roller 3 pass through the bearing seat One 11 is rotatably connected to the frame 1, one side of the spraying fixed roller 3 passes through the bearing seat 1 and is connected to a drive motor 12; the two ends of the spraying moving roller 4 are connected to a bearing seat 2 13, and the bearing seat 2 13 is slidably connected to the Above the frame 1; in the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com