Hollow concrete-filled steel pipe support, prefabricated part, construction method, and supporting system

A hollow steel pipe and concrete technology, applied in excavation, infrastructure engineering, construction, etc., can solve the problems of restricting on-site construction progress, non-conformance, labor and material resources, etc., to facilitate factory production, easy transportation and installation, installation and The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

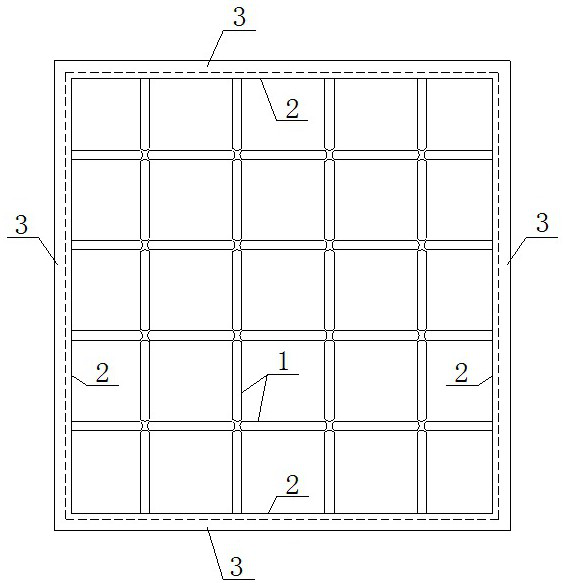

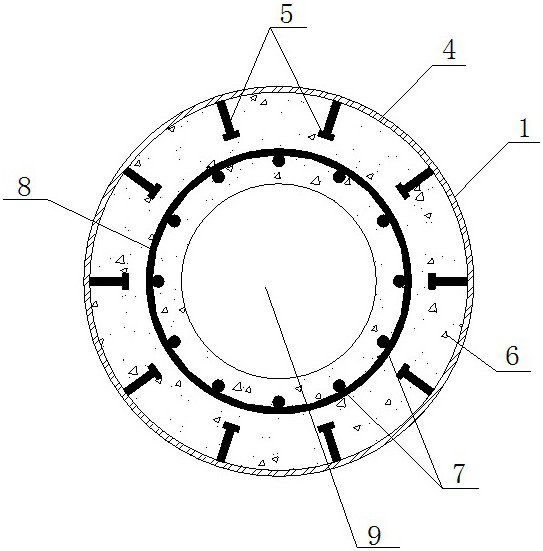

[0038] Such as Figure 2-Figure 4 As shown, this embodiment provides a hollow steel tube concrete support prefabricated part 1, which includes a steel tube 4 and a joint steel plate 10, the steel tube 4 is filled with concrete 6, and the concrete 6 has a hollow part 9 penetrating in the axial direction; The concrete 6 is equipped with a steel skeleton; both ends of the steel pipe 4 are welded with annular joint steel plates 10, the inner side of the joint steel plate 10 is connected with the steel skeleton, and the outer side of the joint steel plate 10 is located on the Steel pipe 4 outside. The hollow concrete-filled steel tube support prefabricated part 1 of this embodiment is a hollow member filled with concrete 6 inside the steel tube 4, which can not only give full play to the advantages of the two materials of steel and concrete, but also has high cost performance. Compared with the pure steel support, it has significant economic benefits. Compared with the concrete su...

Embodiment 2

[0047] Such as Figure 2-Figure 4 As shown, the present embodiment provides a construction method for the hollow concrete-filled steel tube support prefabricated part 1, including the following steps:

[0048] S1. According to the design drawings, prepare steel pipe 4, joint steel plate 10, spiral stirrup 8, longitudinal reinforcement 7, stiffening plate, joint inner liner 14, joint outer liner 13 and inner cladding pipe 15;

[0049] S2. The steel pipe 4 has reserved studs 5 on its inner wall during production, and the spiral stirrup 8 and longitudinal reinforcement 7 are arranged in the steel pipe 4;

[0050] S3, welding joint steel plates 10 at both ends of the steel pipe 4;

[0051] S4. Weld the joint inner lining pipe 14 and the joint outer lining pipe 13 on the inner side and the outer side of the two ends of the steel pipe 4, so that the joint inner lining pipe 14 and the joint outer lining pipe 13 are connected with the steel pipe 4 and the joint steel plate 10;

[00...

Embodiment 3

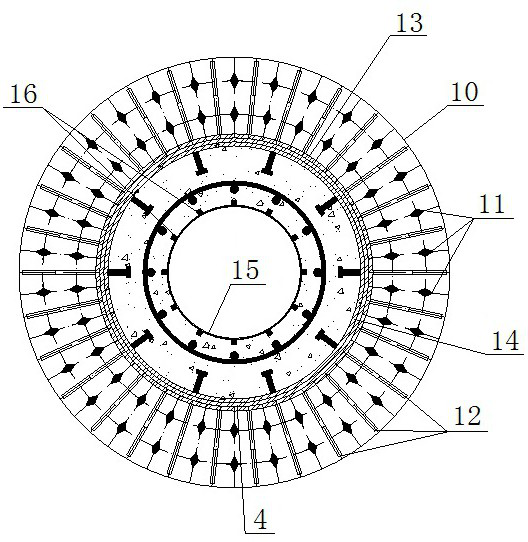

[0058] Such as image 3 As shown, this embodiment provides a hollow concrete-filled steel pipe support, which is formed by splicing a plurality of hollow concrete-filled steel pipe support prefabricated parts 1 provided in Embodiment 1, or a plurality of hollow steel pipes fabricated by the construction method provided in Embodiment 2 The concrete supporting prefabricated parts 1 are spliced together; the part of the joint steel plate 10 extending outside the steel pipe 4 is provided with a plurality of bolt holes in the circumferential direction, and the adjacent joint steel plates of the adjacent hollow steel pipe concrete supporting prefabricated parts 1 Corresponding bolt holes on the 10 are connected by bolts 11 respectively.

[0059] The hollow concrete-filled steel pipe support in this embodiment is spliced by multiple hollow concrete-filled steel pipe support prefabricated parts 1, and the hollow concrete-filled steel pipe support prefabricated part 1 and the hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com