Detachable deck type steel bar truss laminated slab

A reinforced truss and laminated board technology, applied in the direction of floors, building components, buildings, etc., can solve the problems of difficulty in crossing mechanical and electrical pipelines, prolonged construction period, small span of prefabricated panels, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

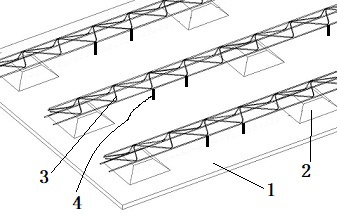

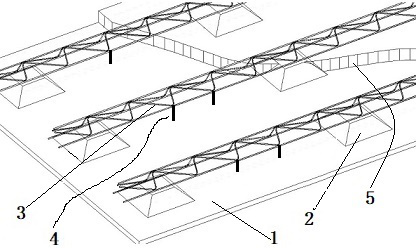

[0026] The most critical idea of the present invention is to place the reinforced truss on the upper surface of the protruding square prism on the prefabricated floor and fix it with bolts. There are connecting steel bars anchored into the prefabricated floor, which are used as the vertical support of the prefabricated floor. The steel truss can be disassembled and used repeatedly, saving materials and reducing waste, reducing the thickness of the plate, and reducing the temporary support under the prefabricated floor.

[0027] In order to describe the technical content, structural features, objectives and effects of the present invention in detail, it will be described in detail in conjunction with the implementation and accompanying drawings.

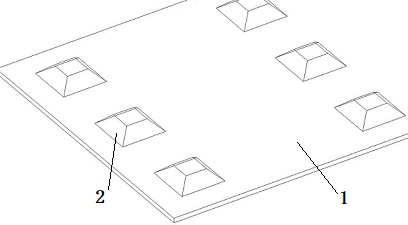

[0028] see figure 1 , figure 2 , image 3 , Figure 4 , the detachable top-loading reinforced truss composite plate of the present invention includes a prefabricated bottom plate 1, a protruding square prism 2, a steel bar truss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com