Fireproof heat-insulation pine solid door and production process thereof

A production process and solid door technology, which is applied to fire doors, wood processing appliances, door leaves, etc., can solve the problems of unsatisfactory fire and heat insulation effects of solid wood doors, so as to improve the effect of fire prevention, accelerate distribution, and avoid aspiration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

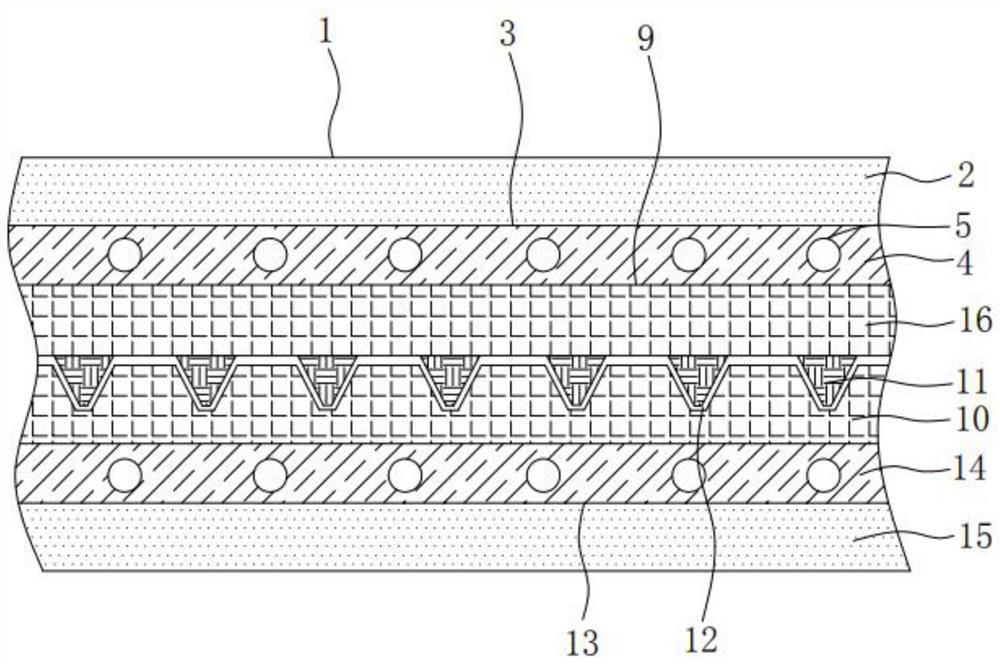

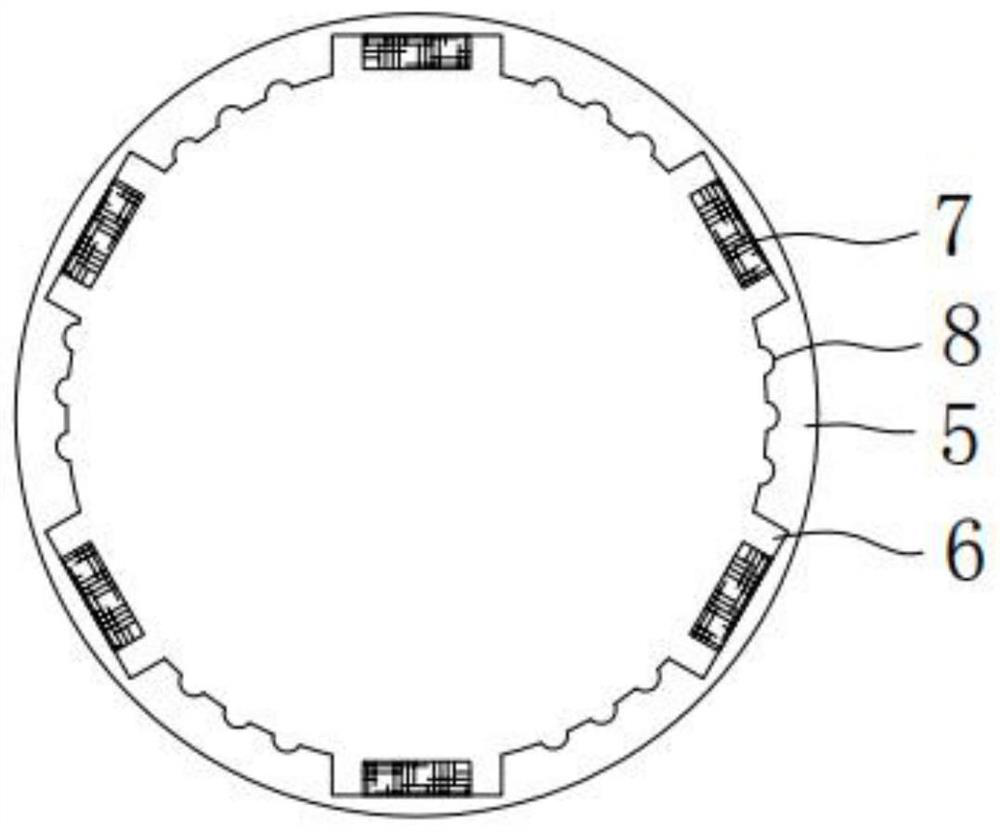

[0028] see Figure 1-2 , the present invention provides a fireproof and heat-insulated pine wood solid door technical solution: including a door body 1, a first fire-retardant layer 2 is arranged inside the door body 1, and a first fire-retardant layer 2 is arranged on the bottom of the first fire-proof layer 2 The fireproof layer 3, the inside of the first fireproof layer 3 is provided with a first fireproof board 4, the inside of the first fireproof board 4 is provided with a heat dissipation hole 5, and the inside of the heat dissipation hole 5 is provided with a ventilation hole 6, so The ventilation hole 6 is provided with an adsorption block 7, the inside of the heat dissipation hole 5 is provided with a diversion groove 8 on one side of the ventilation hole 6, and the bottom of the first fireproof layer 3 is provided with a strengthening layer 9. The interior of the reinforcement layer 9 is respectively provided with a first reinforcement board 16 and a second reinforce...

no. 2 example

[0059] Based on the production process of a fire-proof and heat-insulating pine solid door in the first embodiment of the present invention, the second embodiment of the present invention provides another production process of fire-proof and heat-insulating pine solid door, wherein the second embodiment does not It hinders the independent implementation of the technical solution of the first embodiment.

[0060] Specifically, the difference in the production process of the present invention for providing another fireproof and heat-insulating pine wood solid door is that it includes the following steps:

[0061] S1. Process the pine solid door into a standard size according to the processing size standard of the pine solid door, and then clean and remove the sawdust impurities remaining on the pine solid door, and then obtain the pine solid door embryo;

[0062] S2. After the door blank is obtained, the surface of the door blank is polished by external grinding equipment;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com