Low-temperature drying device for camellia seed

A low-temperature drying technology for camellia oleifera seeds, applied in drying, drying machines, heating devices, etc., can solve the problems of uneven drying, tea seeds cannot be turned over in time, and achieve the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

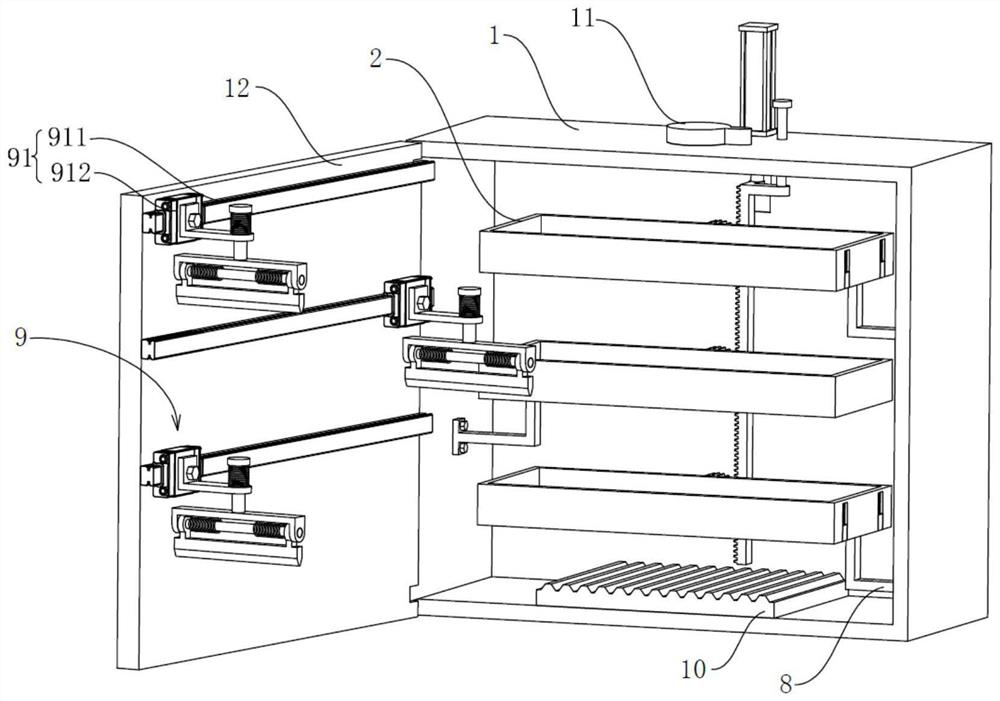

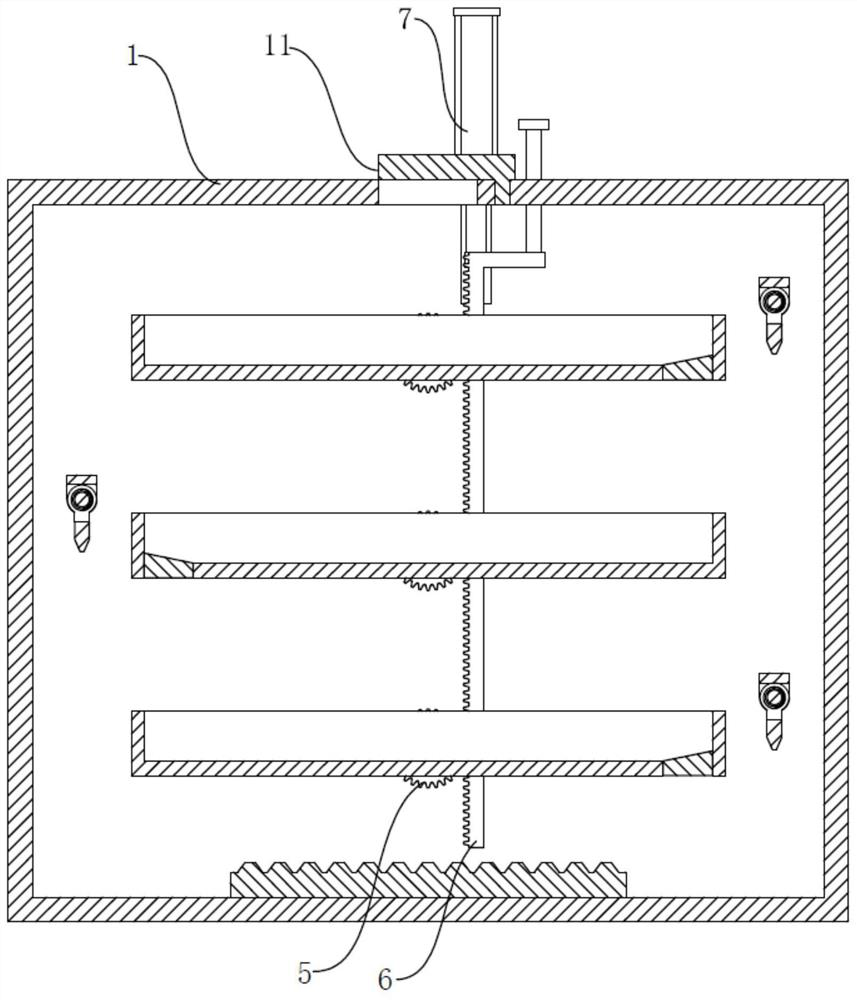

[0022] see Figure 1 to Figure 4 , the present invention provides a technical solution:

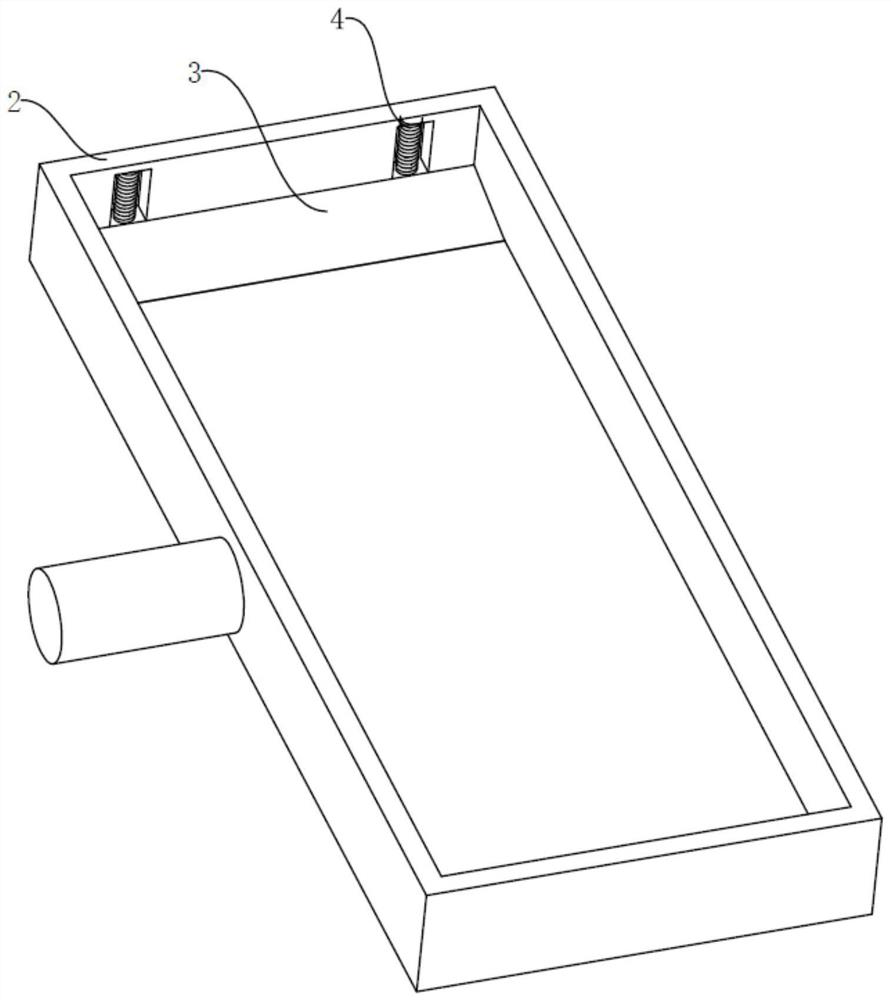

[0023] A low-temperature drying device for camellia oleifera seeds, comprising a drying box 1, a hopper 2, a slope-shaped sealing plate 3, a spring I 4, a gear 5, a rack 6, a hydraulic cylinder 7, a push rod 8, a turning mechanism 9 and heating plate 10, wherein:

[0024] A baffle plate 11 is installed on the feed opening at the top of the drying box 1, so when the baffle plate 11 breaks away from the feed opening at the top of the drying box 1, the Camellia oleifera seeds to be dried can be added, and the side of the drying box 1 is hinged with The cabinet door 12 and the heating plate 10 are arranged at the inner bottom of the drying box 1, so the interior of the drying box 1 presents a temperature gradient from bottom to top;

[0025] At least two hoppers 2 are respectively installed inside the drying box 1 through the rotating shafts at their ends, wherein the hoppers 2 are distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com