Treatment of leather including employing pectin

A technology of leather and pectin, which is applied in the field of leather manufacturing and can solve problems such as release problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0071] Materials and methods

[0072] pectin

[0073] Two commercial citrus pectins were obtained: CT 01 (low methoxyl) and CT 02 (amidated), and a beet pectin SB 01 (high methoxyl). All of these pectins are extracted and processed at the supplier. Pectin is not enzymatically treated at the supplier. For leather application tests, these pectins were used unmodified (unmodified pectin) and modified (enzymatically hydrolyzed and / or demethoxylated) to give partially enzymatically hydrolyzed pectin, demethoxylated Pectin or partially enzymatically hydrolyzed demethoxylated pectin.

[0074] Table 1: Unmodified pectin samples used in this study

[0075] pectin source Degree of methoxylation[%] Amidation degree [%] Remark CT 01 Tangerine 37-38 - low methoxy CT 02 Tangerine 29-30 21 amidation SB 01 beet 54-65 - high methoxyl

[0076] enzyme

[0077] Endopolygalacturonase M2 (Aspergilus aculeatus), a pectin hydrolase, was o...

Embodiment 1

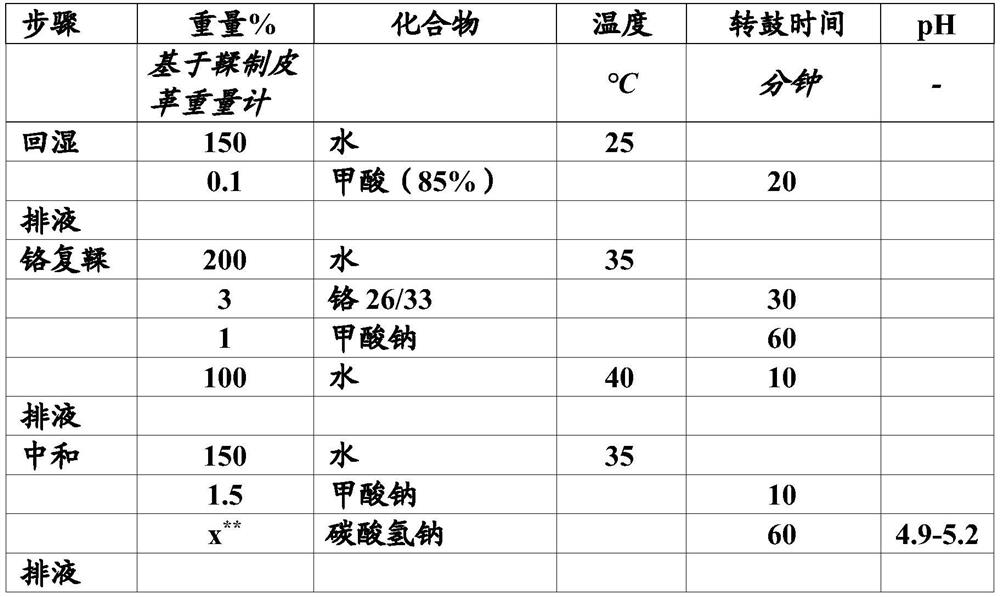

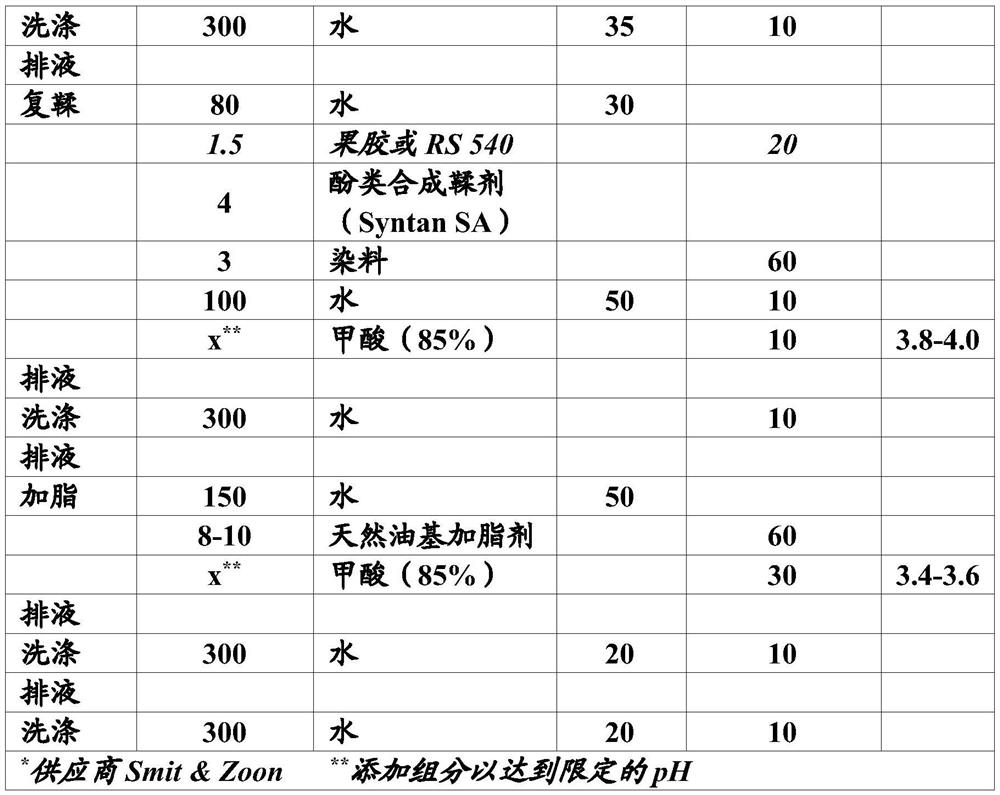

[0094] Wet blue (WB) bovine leather (thickness 1-2 mm) was treated according to the basic recipe in Table 3, wherein 1.5% (weight of shaved leather based on WB) was applied during retanning after mineral retanning and neutralization. ) unmodified citrus pectin CT 02, unmodified sugar beet pectin SB 01 or synthetic derivatives (Syntan RS 540 from Smit & zoon) immediately followed by the addition of phenolic retanning agents and dyes.

[0095] Table 3: The post-tanning treatment formulation of Example 1

[0096]

[0097]

[0098] The resulting crust samples were compared to a reference which was treated according to Table 3 with Syntan RS 540 instead of pectin, or treated without the addition of pectin or RS540 Sample (blank). The results are listed in Table 4. Both samples help improve stain intensity and fullness. Softness properties vary.

[0099] Table 4: Sensory evaluation of Example 1 (leather treated with CT 02 relative to blank evaluation, leather treated with ...

Embodiment 2

[0102] Wet blue (WB) bovine leather (thickness 1-2 mm) was treated according to the recipe in Table 3, modified for shoe upper articles, where 1- 2% (active matter, based on WB shaved leather) of partially enzymatically hydrolyzed citrus pectin CT 01 (H-CT 01), partially enzymatically hydrolyzed beet pectin SB 01 (H-SB 01 pectin ) or synthetic derivatives (Syntan RS 540 from Smit&Zoon), followed immediately by the addition of phenolic retanning agents and dyes.

[0103] Table 5: Sensory evaluation of Example 2 (all samples vs reference WB treated with Syntan RS 540)

[0104] H-CT 01 H-SB 01 textured appearance +- +- Dyeing uniformity - - staining intensity +++ +++ texture firmness + +- softness + - Fullness - +-

[0105] The resulting crust samples were compared to a reference, which was a sample of crust similar to the test sample but treated with Syntan RS 540 instead of pectin. The results are listed in Table 5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com