A large-scale shielded main pump main bolt tensioning device and tensioning method

A technology of tensioning device and main bolt, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems such as affecting the critical path of overhaul or unplanned downtime, the main bolt taking a long time, and being difficult to control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

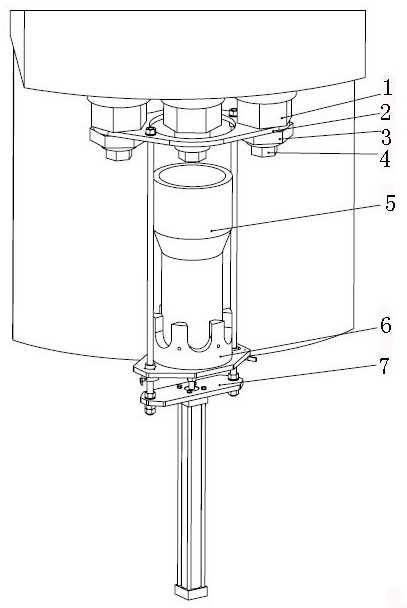

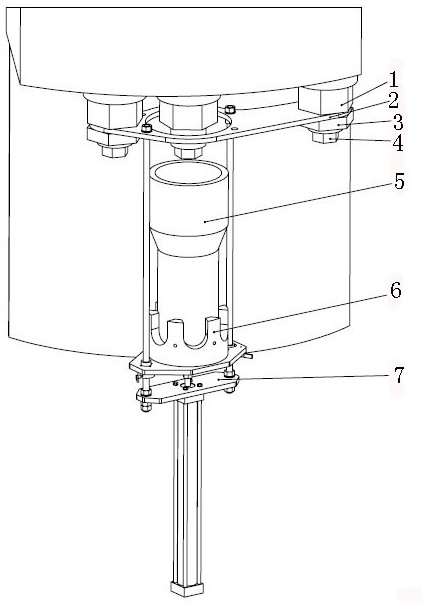

[0082] A main bolt tensioning device of a large-scale shielded main pump includes a tensioning mechanism, a disassembly assembly of the tensioning mechanism, and a pneumatic control system.

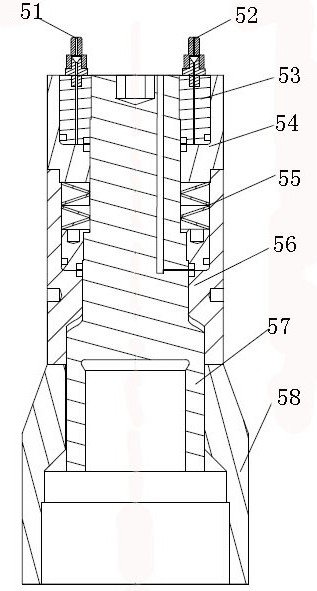

[0083] Such as figure 1 As shown, the stretching mechanism includes a piston cylinder, a bridge frame 58 , a stretching rod 57 , a piston, an oil inlet pipe 51 and an oil return pipe 52 . The bridge frame 58 is connected to the axial bottom end of the piston cylinder, and the bottom is provided with an open groove. The axial bottom end of the stretch rod 57 is provided with a threaded connection hole facing the opening groove, and the axial top end is provided with a limiting installation groove. The piston is arranged inside the piston cylinder and socketed with the stretch rod 57 . One mouth of the oil inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com