Production device and process for prefabricated part

A technology for production equipment and prefabricated parts, applied in the direction of manufacturing tools, ceramic molding workshops, ceramic molding machines, etc., can solve the problems of low production efficiency of prefabricated parts, achieve low production efficiency, save time, improve quality and production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present application will be described in further detail below in conjunction with drawings 1-5.

[0049] The embodiment of the present application discloses a prefabricated part production equipment.

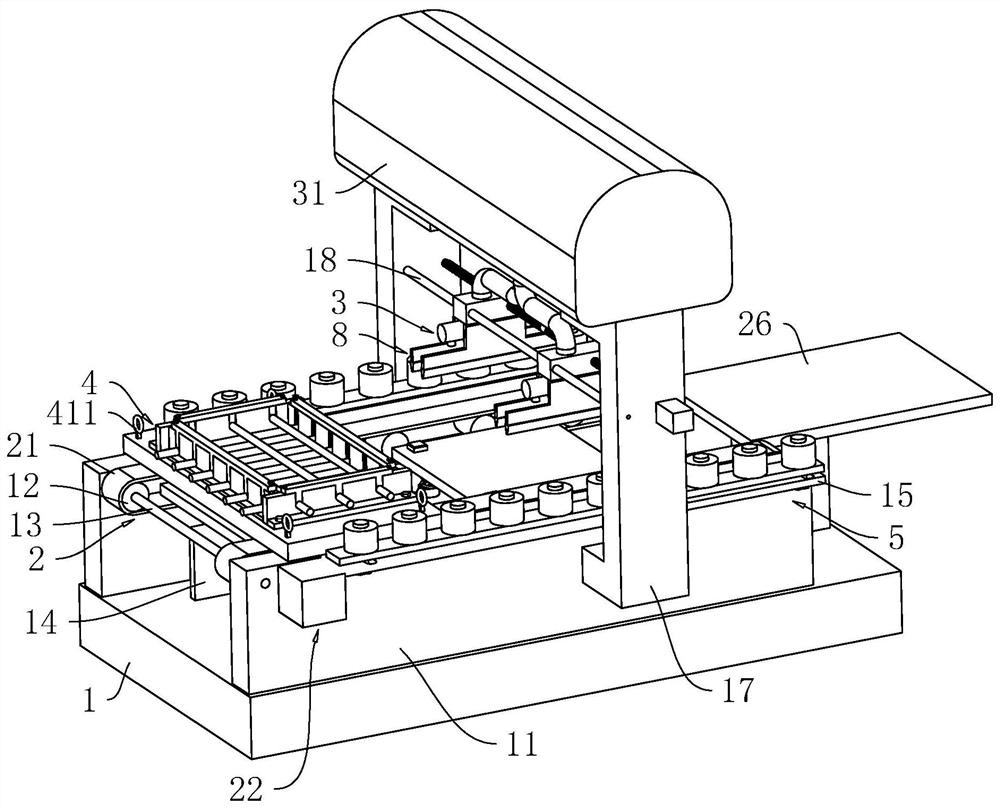

[0050] refer to figure 1 , The preform production equipment includes a frame 1 , a conveying mechanism 2 and a filling mechanism 3 arranged on the frame 1 .

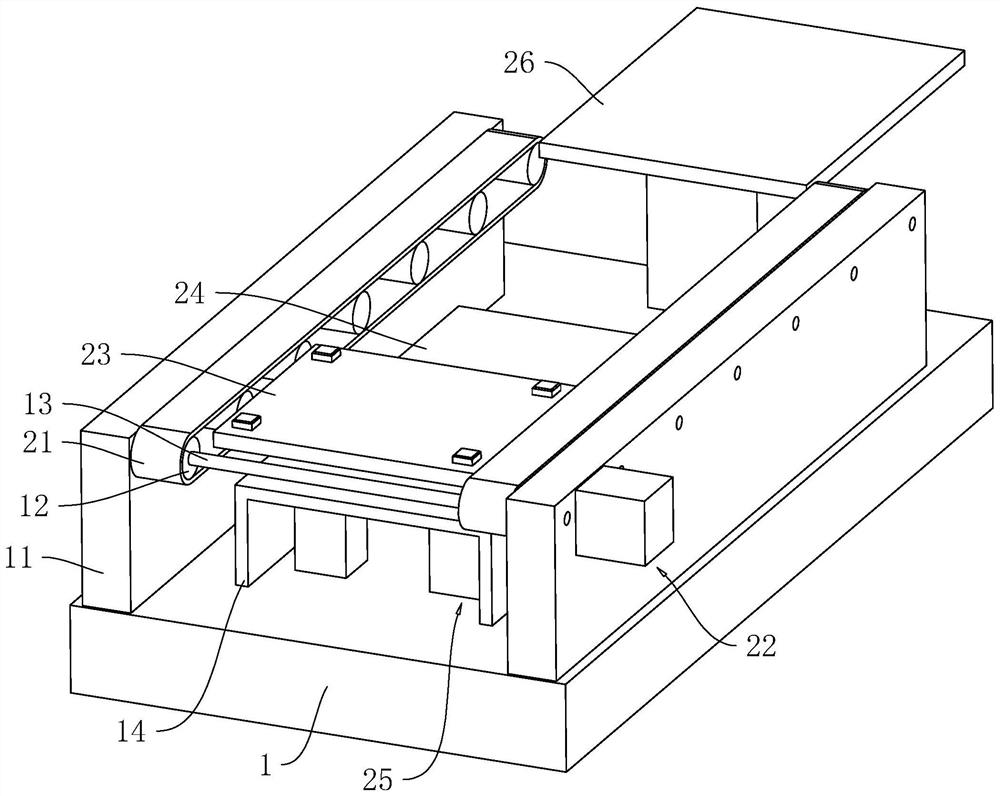

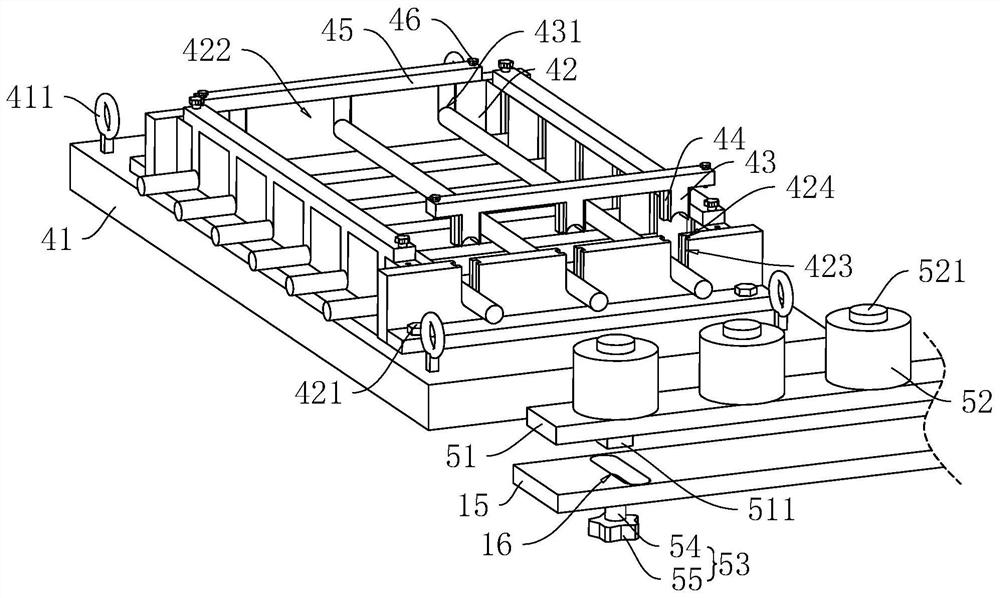

[0051] refer to figure 1 with figure 2 The conveying mechanism 2 includes a conveyor belt 21, a driver 22, a first lifting platform 23, a second lifting platform 24, a lifting assembly 25, and a receiving platform 26. Two mounting plates 11 are fixedly installed on the upper surface of the frame 1 at intervals. On the side wall on the opposite side of the block mounting plate 11, a conveying wheel 12 is rotated and installed, and a plurality of conveying wheels 12 are evenly distributed along the lengthwise direction of the mounting plate 11, two conveying wheels 12 near one end of the mounting plate 11 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com