Product transporting and packaging equipment for brickyard production

A technology for finished products and brick factories, which is applied in the field of finished product transportation and packaging equipment for brick factory production. It can solve the problems of blockage and line stoppage in cyclic packaging production, unstable brick accumulation and collapse, loose and collapsed bricks, etc., and achieve accurate and stable automatic packaging. Work, time-saving and labor-saving production efficiency, the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

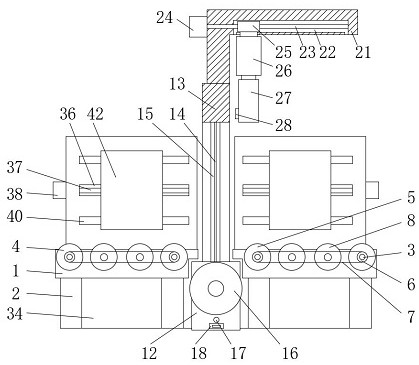

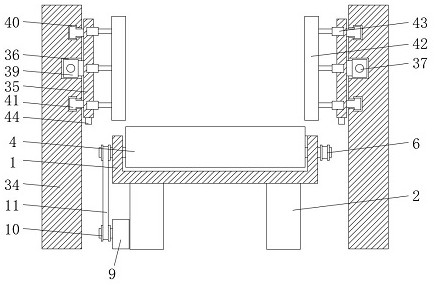

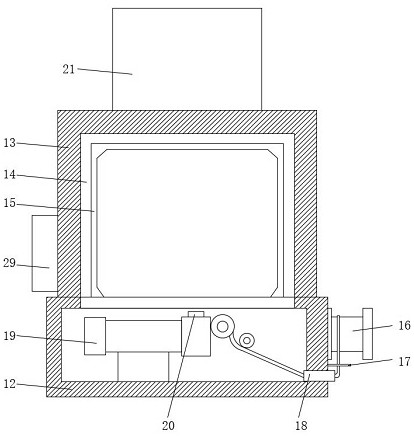

[0025] Such as Figure 1-4As shown, the embodiment of the present invention provides a finished product transportation and packaging equipment for brick factory production, including two transmission frames 1, the bottoms of the two transmission frames 1 are fixedly connected with support columns 2, and both transmission frames 1 are rotated A plurality of rotating shafts 3 are connected, wherein two sets of rotating shafts 3 are respectively connected with driving rollers 4 and driven rollers 5, and the bottoms of the two transmission racks 1 are provided with first motors 9 on the side close to the driving rollers 4. The driving ends of the two first motors 9 and one end of the rotating shaft 3 on the two driving rollers 4 are all provided with a second pulley 10, and the two sets of second pulleys 10 are correspondingly connected with a second belt 11. A packing box 12 is arranged at the position between the transmission racks 1, and the top of the packing box 12 is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com