Earphone connecting wire winding forming device for earphone production

A technology of winding and forming and connecting wires, which is applied in the directions of earphone manufacturing/assembly, earpiece/earphone accessories, transportation and packaging, etc., which can solve the problem of low stability and convenience of earphone cord winding, unstable process, winding sleeve forming Inhomogeneity and other problems to achieve the effect of improving stability, convenience and scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

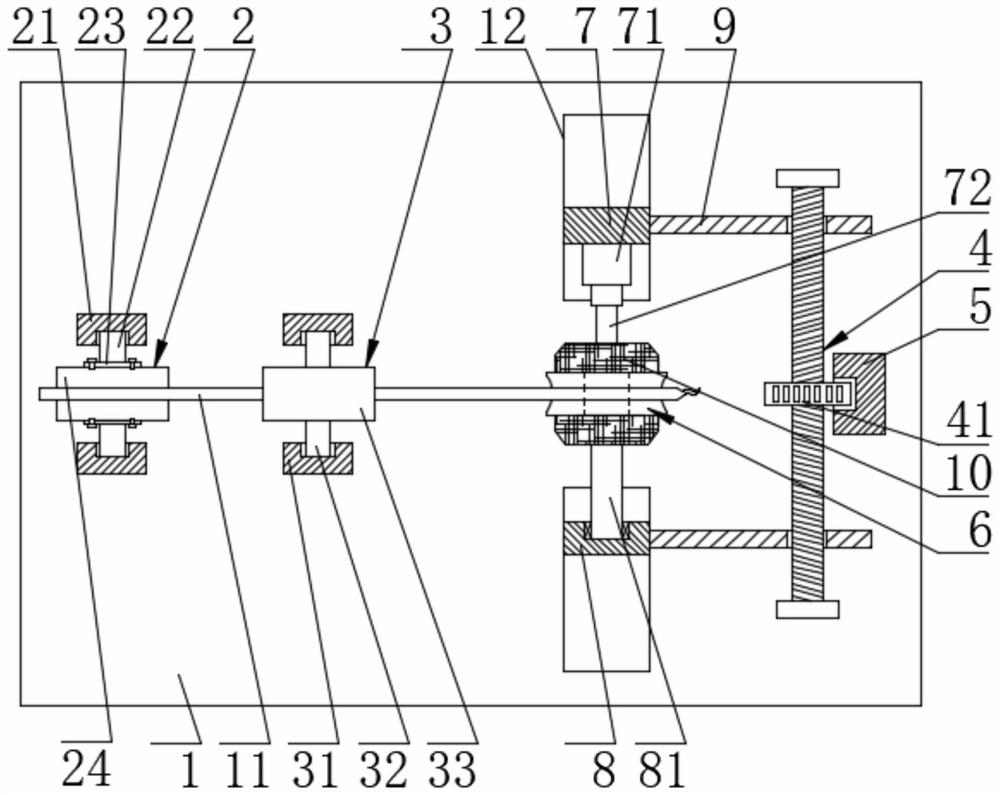

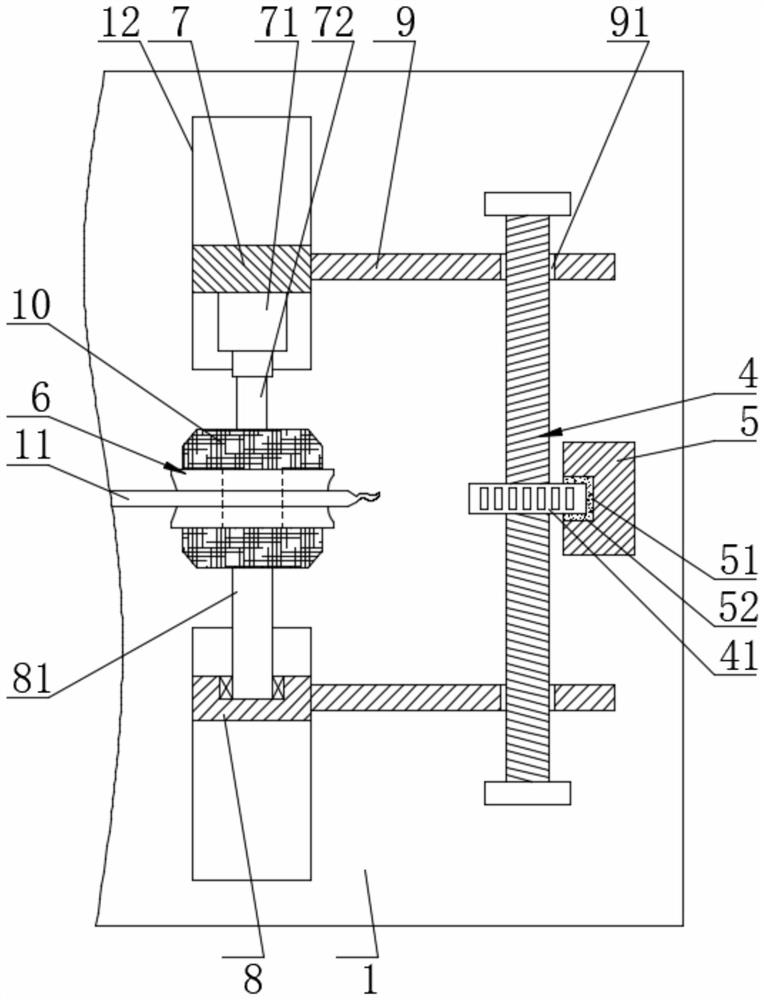

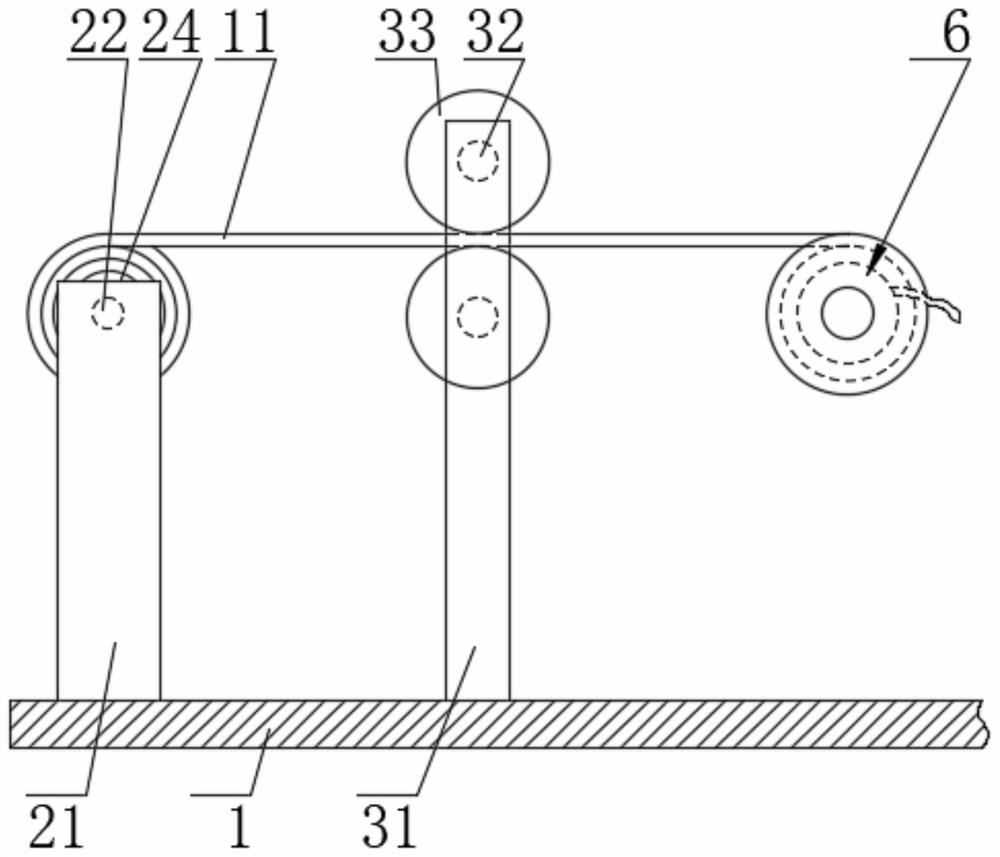

[0023] See figure 1 , image 3 , Figure 5 A headset with a headphone cable is wound producing molding apparatus, comprising a winding package 6 rings, double thread rod 4, provided in the main chassis and the discharge line roller group 2, group 3 on the line roller 1, fixed baffle plate 5, Actinomyces roller group 2, the winding roll 6 ring packing sleeve body 11 has a headphone cable, actinomycetes roller group 2 by a first holder 21, a first shaft 22 is inserted, the mounting plate 23, the discharge roller 24 composed of wire, wire roll group 3 by a second bracket 31, the second shaft 32 is inserted, the lead roll 33. the number of wires to two rollers 33 and a transverse axis of the body 11 of the earphone line symmetrically to the center of the winding package 6 ring I-shaped cross section structure, which has a through-hole preset.

[0024] See figure 1 , figure 2 , Figure 4 The main plate is provided with the guide runner 12, the number of the guide runner 12 and two transve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com