Liquid-gas two-phase medium coupling mobile injection sintering method and injection device

A sintering method and injection device technology, which is applied in the fields of injection sintering, liquid-gas two-phase medium coupling mobile injection sintering, liquid-gas two-phase medium coupling mobile injection device, and can solve high production costs and insufficient combustion energy, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

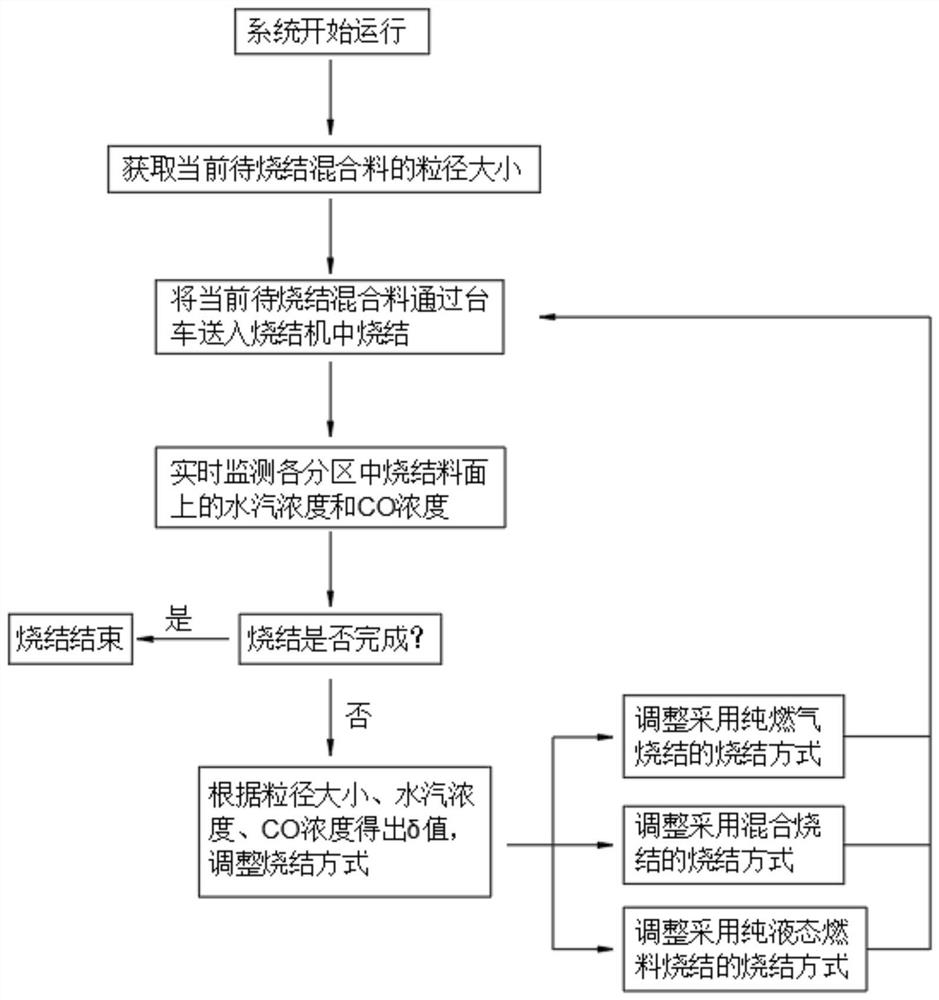

[0099] According to the first embodiment of the present invention, a liquid-gas two-phase medium coupled mobile jet sintering method is provided:

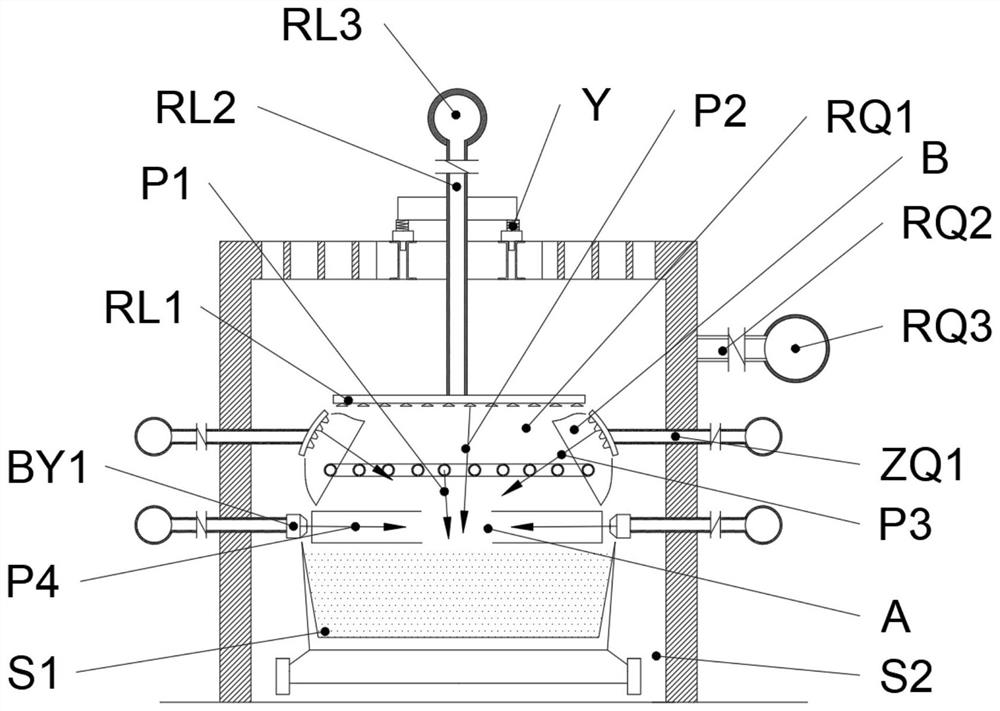

[0100] A liquid-gas two-phase medium coupling mobile injection sintering method, the method includes the following steps: 1) Obtain the particle size D of the current mixture to be sintered; 2) Send the mixture to be sintered into a sintering machine through a trolley for sintering , spray gaseous fuel to the sintering material surface of the trolley in an integral form, and spray liquid fuel to the material surface of the trolley in a moving form; 3) monitor in real time when the mixture to be sintered is sintered on the trolley, and obtain current Water vapor concentration C on the sintered surface 水 and CO concentration C CO ; 4) according to step 1) and step 3) data D, C 水 、C CO , compare it with the historical average data stored in the system, select one of the injection sintering methods of pure gaseous fuel sintering, pu...

Embodiment 1

[0131] According to the first embodiment of the present invention, a liquid-gas two-phase medium coupled mobile jet sintering method is provided:

[0132] A liquid-gas two-phase medium coupling mobile injection sintering method, the method includes the following steps: 1) Obtain the particle size D of the current mixture to be sintered; 2) Send the mixture to be sintered into a sintering machine through a trolley for sintering , spray gaseous fuel to the sintering material surface of the trolley in an integral form, and spray liquid fuel to the material surface of the trolley in a moving form; 3) monitor in real time when the mixture to be sintered is sintered on the trolley, and obtain current Water vapor concentration C on the sintered surface 水 and CO concentration C CO ; 4) according to step 1) and step 3) data D, C 水 、C CO , compare it with the historical average data stored in the system, select one of the injection sintering methods of pure gaseous fuel sintering, pu...

Embodiment 2

[0134] Repeat embodiment 1, but in step 4), data is substituted into formula (1), obtains the judgment parameter δ of the sintered material surface everywhere in the sintering machine;

[0135]

[0136] Judging the size of δ, choose the injection sintering method:

[0137] When δ≤1, the sintering method of pure gaseous fuel injection sintering is adopted;

[0138] When 1<δ≤2, the sintering method of mixed injection sintering is adopted;

[0139] When δ>2, the sintering method of pure liquid fuel injection sintering is adopted;

[0140] Among them, D, C 水 、C CO The units are mm, %, %; D 平均 is the historical average particle size of the mixture to be sintered, mm; C 水平均 is the historical average volume concentration of water vapor during sintering, %; C CO平均 is the historical average volume concentration of CO during sintering, %; k1 is the coupling coefficient of particle size, the value is 0.6-1.2; k2 is the coupling coefficient of water vapor concentration, the value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com