Replaceable high-strength prefabricated assembled pier

A technology of prefabricated assembly and prefabricated piers, which is applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of large site workload, long maintenance period, environmental traffic impact, etc., and achieve simple construction methods, high construction efficiency, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

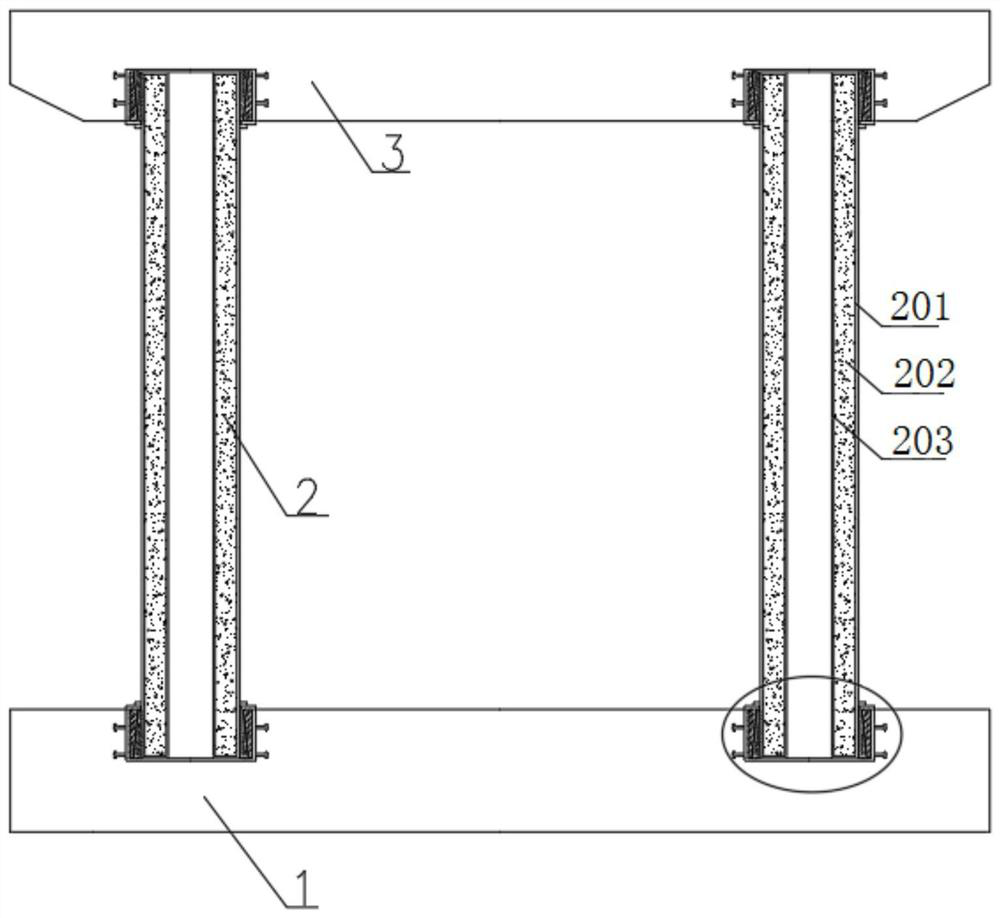

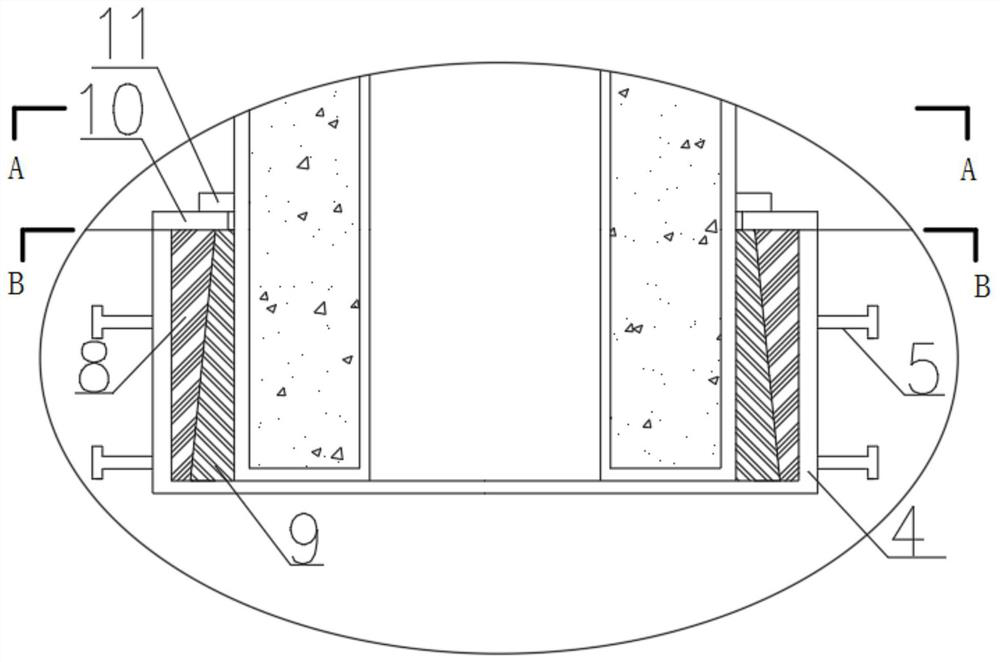

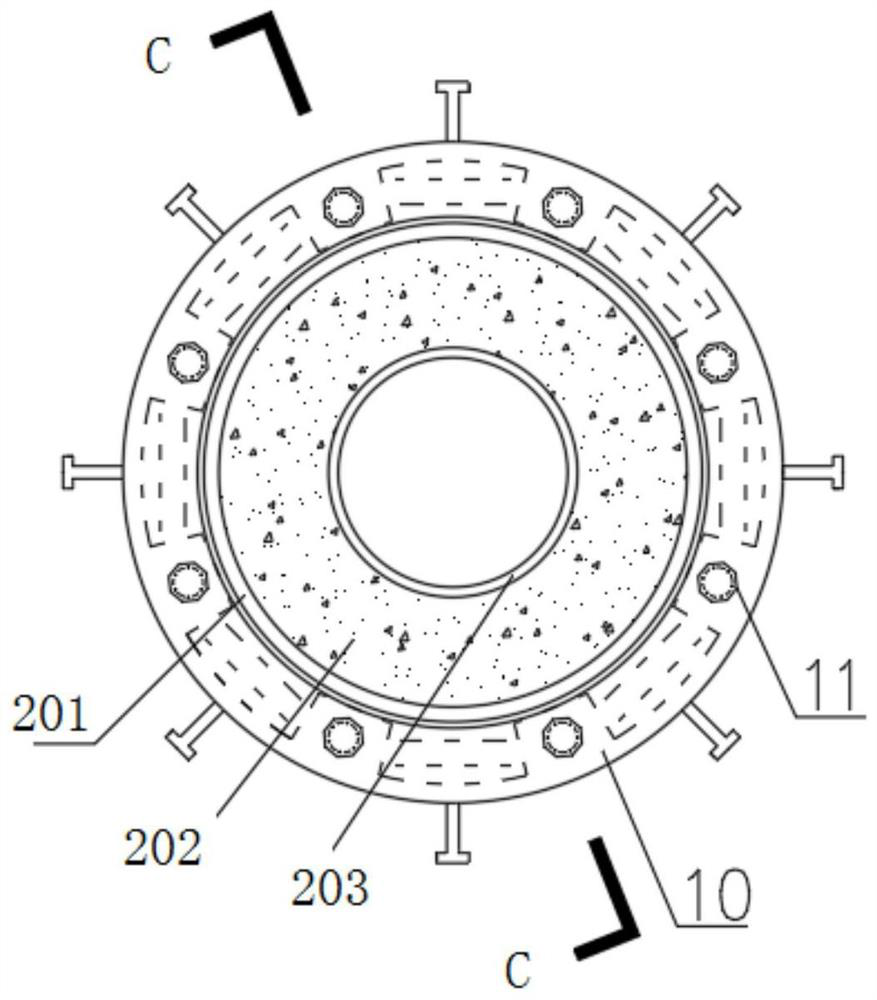

[0045] See Figure 1 to Figure 6As shown, this embodiment proposes a replaceable high-strength prefabricated assembled bridge pier, including a cap 1, a prefabricated pier column 2 arranged on the cap 1, and a cover beam 3 arranged on the prefabricated pier column 2, The upper and lower ends of the prefabricated pier column 2 are fixedly connected with the connection structure pre-embedded in the platform 1 and the cover beam 3 respectively. The sleeve 4 is provided with a number of fixing blocks 6 on the inner wall of the sleeve 4, and the inner surfaces of all the fixing blocks 6 jointly surround and form a cavity for matching and inserting the upper end or the lower end of the prefabricated pier 2.

[0046] see you again figure 1 As shown, the prefabricated pier column 2 is composed of an inner steel pipe 203, an outer steel pipe 201 sleeved outside the inner steel pipe 203, and a concrete 202 poured between the inner steel pipe 203 and the outer steel pipe 201, wherein th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com