Blockage monitoring device of sorting equipment and control method of blockage monitoring device

The technology of a monitoring device and a control method is applied in the direction of a device in which the axial direction of the swirling flow can be reversed, a swirling flow device, etc., which can solve problems such as heavy workload, affecting the effect of material sorting, and affecting the sorting of coarse materials, and achieve The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

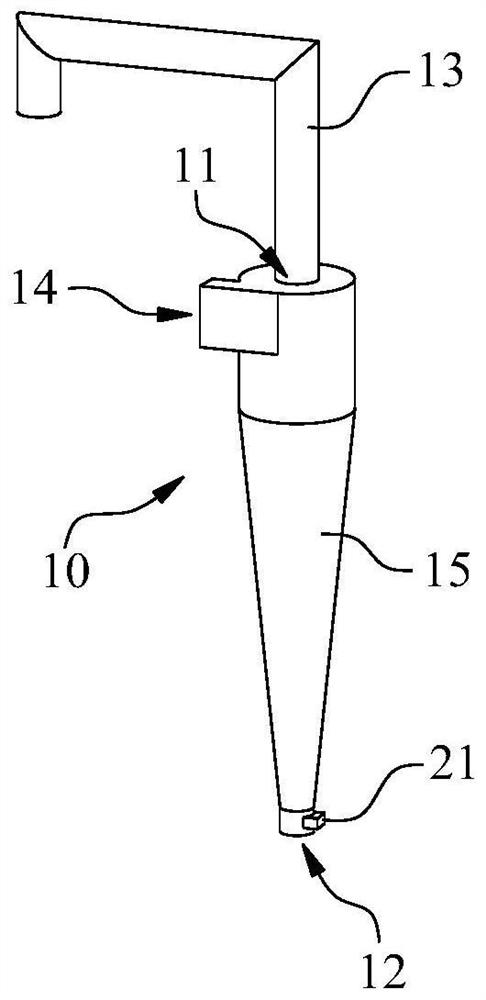

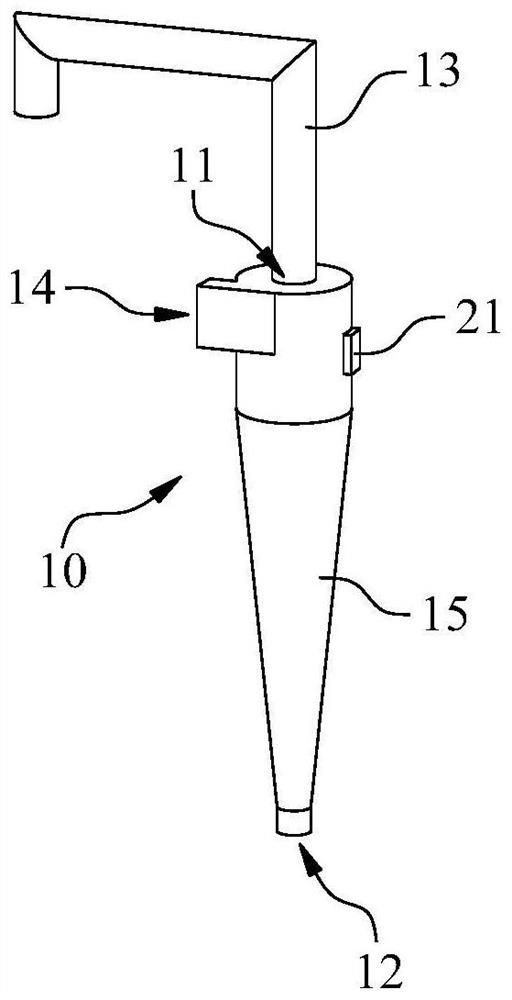

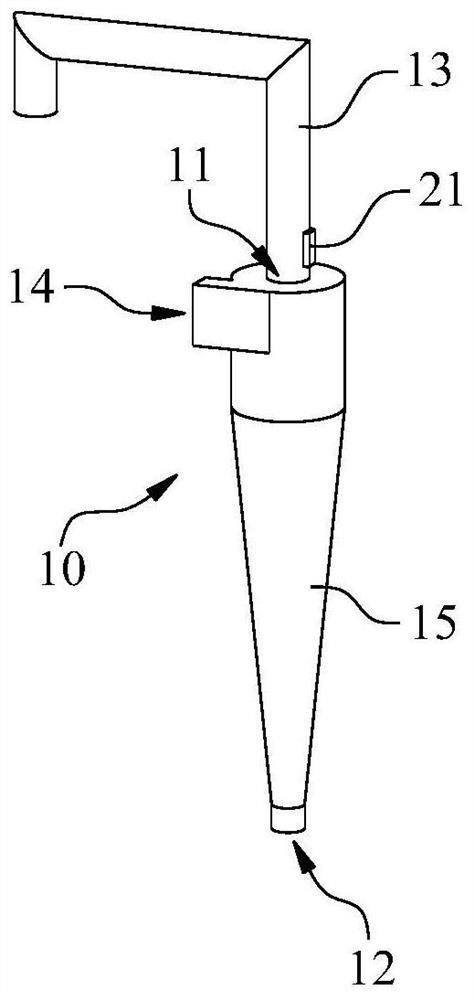

[0028] A clogging monitoring device for sorting equipment, including a cyclone 10, the cyclone 10 includes a first discharge port 11 communicated with a first material cavity 31 through a material guide pipe 13, and the opening is arranged in a second material cavity 32 The second discharge port 12 inside and the feed port 14 communicating with the mixing chamber 33, the first discharge port 11 or the second discharge port 12 are provided with a monitoring sensor 21, and the monitoring sensor 21 is connected to the alarm unit 50.

[0029] When the cyclone 10 is used to classify the particle size of the mineral material, since the movement speed of the mineral material in the cyclone 10 is fast and the hardness of the mineral material is relatively high, if the detection element of the monitoring sensor 21 is set in the cyclone 10 The cavity wall is easily damaged by the flowing mineral material, so the monitoring sensor 21 is set on the outer wall of the cyclone 10 in this embo...

Embodiment 2

[0034] The difference between this embodiment and the first embodiment lies in that several cyclones 10 are arranged in parallel, and the feed inlet 14 of each cyclone 10 communicates with the same mixing chamber 33 . Monitoring sensors 21 are respectively provided at the same part of each cyclone 10 , each monitoring sensor 21 is connected to a control unit 40 , and the control unit 40 is connected to an alarm unit 50 . That is, monitoring sensors 21 are respectively provided at the first discharge ports 11 of each cyclone 10 or monitoring sensors 21 are respectively provided at the second discharge ports 12 of each cyclone 10 . It should be further explained that the arrangement positions of the monitoring sensors 21 on each cyclone 10 should be the same or similar, so as to avoid deviations or errors in the detection results caused by different detection positions of the monitoring sensors 21 . In this way, if the discharge port of a certain cyclone 10 is blocked, the tempe...

Embodiment 3

[0039] The difference between this implementation and Embodiment 1 is that the feed inlet 14 of the cyclone 10 or its barrel 15 is provided with a reference sensor 22, and the monitoring sensor 21 and the reference sensor 22 are respectively connected with the control unit 40, and the control unit 40 The alarm unit 50 is connected; the reference sensor 22 and the monitoring sensor 21 are the same sensor.

[0040] In this embodiment, the monitoring sensor 21 is a contact temperature sensor, preferably a patch temperature sensor, which has good monitoring effect, high stability and reliability. The temperature sensing element of the monitoring sensor 21 for monitoring the temperature of the first discharge port 11 is attached to the outer wall of the first discharge port 11, and the temperature sensing element for monitoring the second discharge port 12 is attached to the second discharge port 12. On the outer wall of the material outlet 11 or the material guide pipe 13; the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com